Manufacturing method of electrode, and battery

A manufacturing method and electrode technology, which are applied in electrode manufacturing, electrode collector coating, battery electrodes, etc., can solve problems such as increased viscosity of electrode mixture and coating defects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] According to the preparation steps of the positive electrode, first, the positive electrode active material is dispersed in a solvent together with a conductive auxiliary agent, a binder, etc. by using a kneader such as a biaxial continuous kneader or a planetary mixer to prepare a positive electrode mixture paste. Then, the cathode mixture is coated on the surface of the cathode current collector by using a coater such as a die coater, followed by drying. Finally, a positive electrode mixture layer was formed on the surface of the positive electrode current collector by applying a pressing method on the positive electrode mixture coated on the surface of the positive electrode current collector.

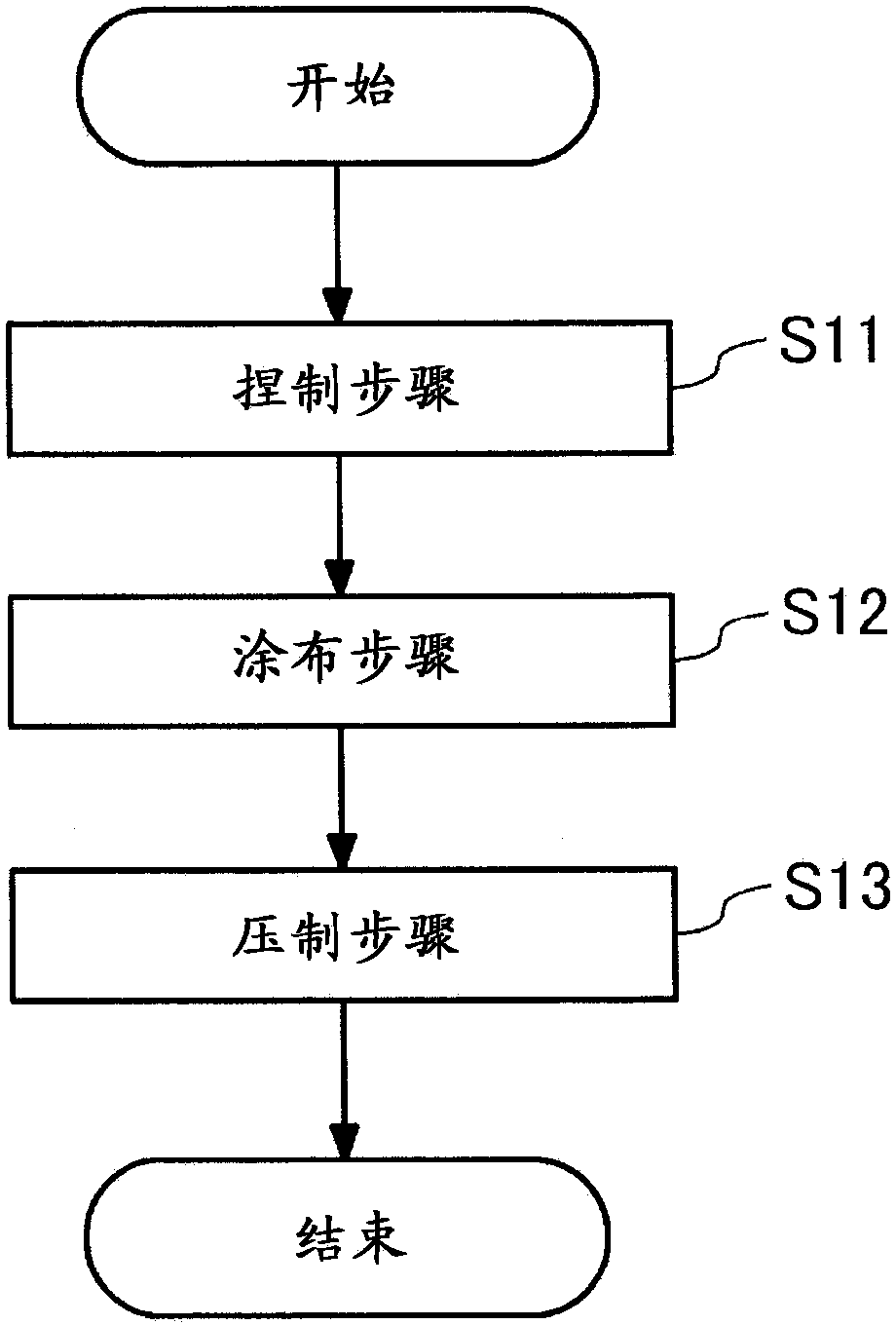

[0029] The preparation step of the negative electrode is a method of manufacturing the electrode related to the embodiment of the present invention. Such as figure 1 As shown in , the preparation steps of the negative electrode include kneading step S11, coating step S12 and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com