Method for monitoring health of rotary machine suitable for working condition changing condition

A technology for rotating machinery and health monitoring, applied in the testing of machines/structural components, measuring devices, instruments, etc., which can solve problems such as difficulties, weak system response changes, and changes in shock and vibration energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

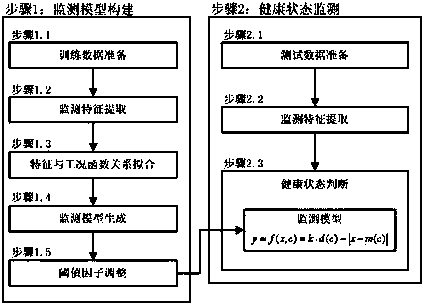

Method used

Image

Examples

Embodiment Construction

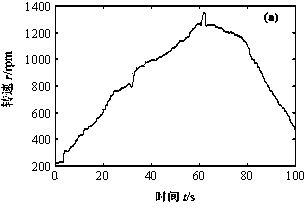

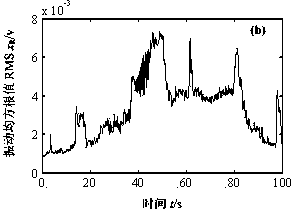

[0029] The specific implementation manner of the present invention will be described below by taking the health monitoring of a bearing, a key component of a rotating machine, as an example. Bearings are an important component of rotating machinery such as engines, gearboxes, pumps, and compressors. Bearing failure is one of the important causes of rotating machinery failure. Bearing health monitoring can detect bearing faults in a timely manner and provide support for maintenance decisions of rotating machinery, thereby avoiding mechanical failure or failure. Therefore, the health monitoring of bearings is very important to maintain the safety of rotating machinery. When the working conditions such as the rotating speed and load of the bearing change, both the normal contact impact energy and the impact vibration energy caused by faults will change. Although the traditional non-stationary signal processing method can deal with the non-stationary signal caused by the change ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com