Water filling device and method for subcritical and above pressure boiler

A water-filling and subcritical technology for boilers, which is applied in the direction of supplementary water supply, preheating, steam generation, etc., can solve the problems of being idle and useless, and achieve the effects of low power consumption, simple equipment, and less operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

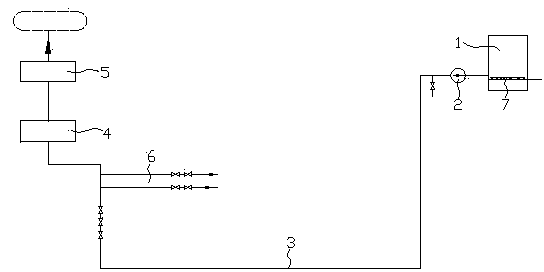

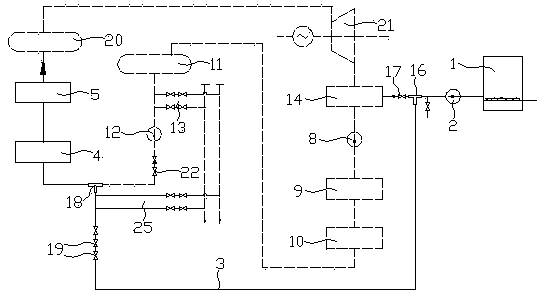

[0017] The water filling method for subcritical and above pressure boilers has the following steps: first put the qualified desalinated water into the desalinated water replenishment water tank, use the condensate replenishment pump to transfer the desalinated water in the desalinated water replenishment water tank through successively connected water filling pipes, three In the process of filling the subcritical and above pressure boiler with water, the desalted water in the pipeline is adjusted by sampling and adding treatment chemicals in the dosing device. Water quality parameters.

[0018] When filling water into subcritical and above pressure boilers, in order to avoid condensation or antifreeze on the metal surface, it is required to fill in desalinated warm water at 20°C~70°C. In order to fill subcritical and above pressure boilers with the above-mentioned Desalinated warm water at a certain temperature, and a heater may be installed in the desalted water replenishment...

Embodiment 2

[0021] The water filling method for subcritical and above pressure boilers has the following steps: put the qualified desalinated water into the desalinated water replenishment water tank, heat the desalinated water in the desalinated water supplementary water tank to desalinated warm water at 20°C~70°C, and other steps With embodiment 1.

[0022] The subcritical and above pressure boiler water filling device can be connected with the subcritical and above pressure boiler water supply device.

[0023] figure 2 Among them, the subcritical and above pressure boiler water supply device connected with the subcritical and above pressure boiler water supply device has a condenser 14 connected in sequence, a condensate pump 8, a condensate polishing device 9, and a three-stage low pressure heater 10 , deaerator 11, high-pressure electric feed water pump 12, three-stage high-pressure heater 4 and economizer 5, there is a device for sampling desalted water in the pipeline and adding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com