Broaching tool mechanism capable of rotating at high speed

A high-speed rotation, bearing seat technology, used in grinding machine parts, other manufacturing equipment/tools, grinding/polishing equipment, etc., can solve problems such as inability to achieve sealing effect, wear of sealing rings, heat at the sealing area, etc. Achieve the effect of reducing labor input, high rotation, and reducing load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

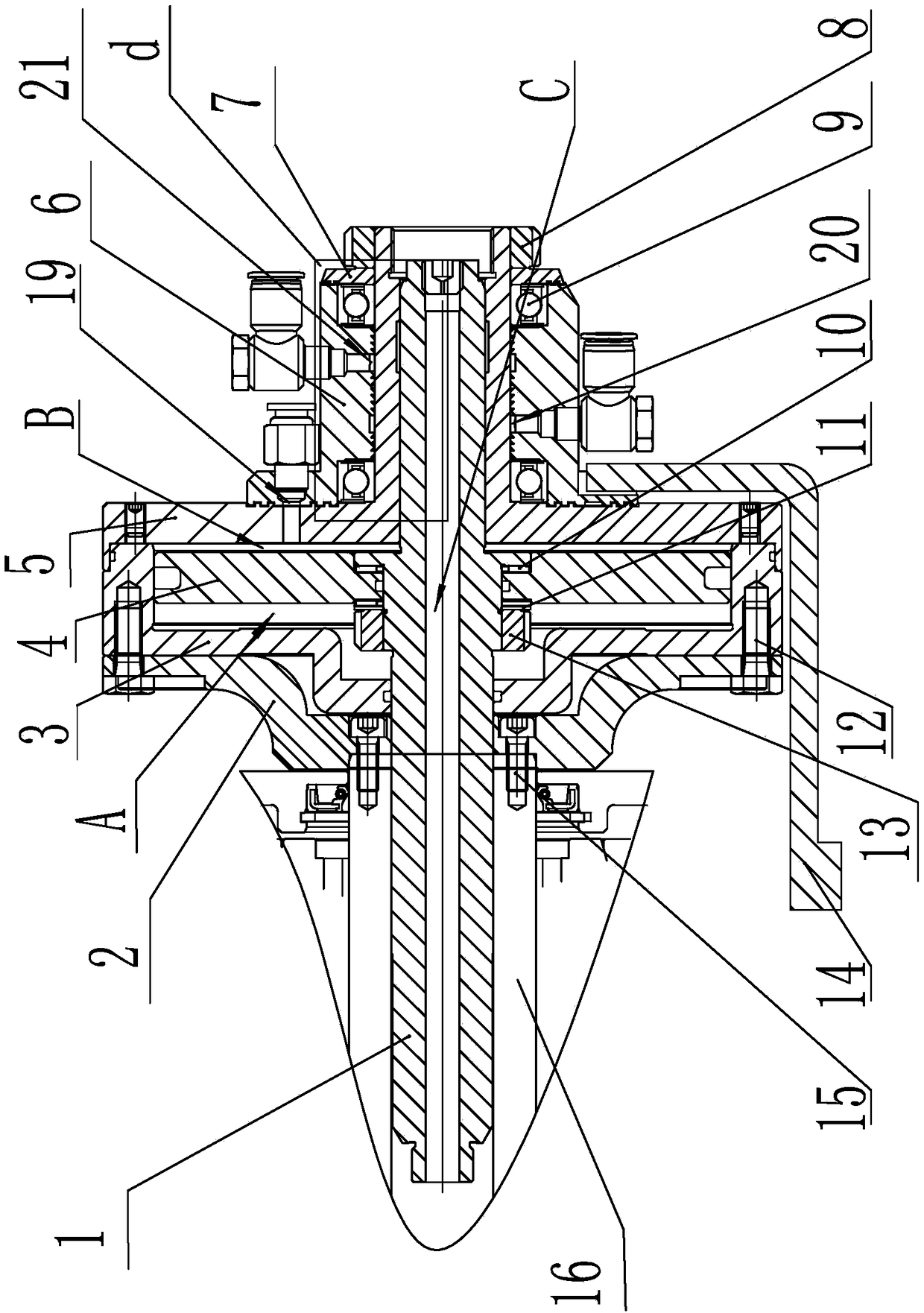

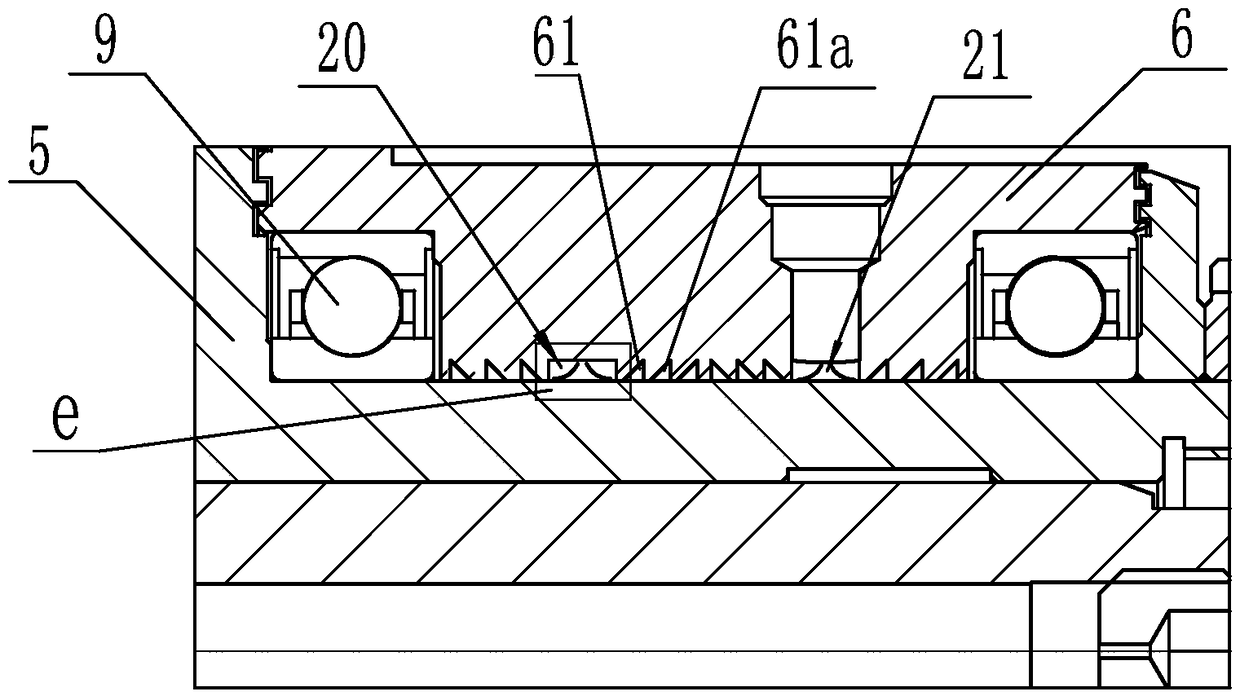

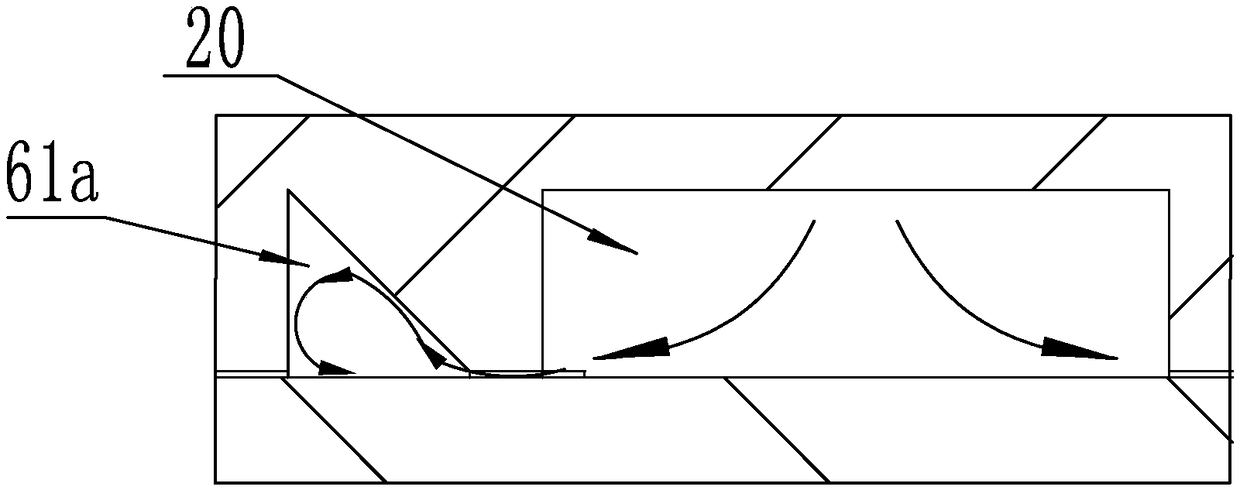

[0023] Such as figure 1 , figure 2 As shown, a high-speed rotating broach mechanism of the present invention comprises a cylinder-piston assembly in which a piston 4 is arranged inside an outer sleeve 3 and a support sleeve 5 with a T-shaped longitudinal section; the piston 4 passes through the central hole A rotary mandrel 1 is set, and the mandrel 1 passes through the outer casing 3 and the support sleeve 5 at both ends in a hermetic manner, and the support sleeve 5 is contacted by two corners respectively arranged at the two ends of the bearing seat 6. The bearing 9 is rotatably connected to the bearing seat 6, the distance between the outer wall of the cylindrical section of the support sleeve 5 and the inner wall of the bearing seat 6 and the distance between the right side wall of the support sleeve 5 and the bearing seat The distances between the left side walls of 6 are all 0.02-0.05 mm. Since the support sleeve 5 and the bearing seat 6 rotate relatively, the cleara...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com