A kind of alkaline zinc-nickel alloy pulse electroplating method with stable nickel content

A zinc-nickel alloy and pulse electroplating technology, which is applied in the field of electroplating zinc-nickel alloy, can solve the problems of fine grain size and unstable nickel content, and achieve the effects of good bonding force, excellent corrosion resistance, and fine crystallization of the coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

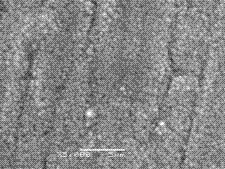

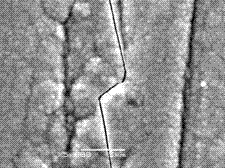

Image

Examples

Embodiment 1

[0036] (1) Preparation of alkaline zinc-nickel alloy plating solution: First, weigh 10g of zinc oxide, 80g of sodium hydroxide, 15g of nickel sulfate hexahydrate, 15ml of ethylenediamine, 10ml of tetraethylenepentamine, 30g of potassium sodium tartrate, and 10g of lemon sodium nitrate, 40ml triethanolamine, 1.5 ml nonionic surfactant, 0.5 g vanillin. Stir the weighed sodium hydroxide and zinc oxide evenly, add 1 / 5 of the total volume of the plating solution in distilled water to dissolve, and stir to dissolve until the solution is clear and transparent, then dilute to 1 / 3 of the total volume, this solution is 1 No. solution; then dissolve the weighed nickel sulfate hexahydrate, potassium sodium tartrate, and sodium citrate respectively, then mix and stir thoroughly, then add the weighed ethylenediamine, tetraethylenepentamine and triethanolamine, stir and mix Evenly, this solution is No. 2 solution. Finally, slowly add No. 2 solution into No. 1 solution, stir while adding, the...

Embodiment 2

[0041] (1) Preparation of alkaline zinc-nickel alloy plating solution: First, weigh 10g of zinc oxide, 80g of sodium hydroxide, 15g of nickel sulfate hexahydrate, 15ml of ethylenediamine, 10ml of tetraethylenepentamine, 30g of potassium sodium tartrate, and 10g of lemon sodium nitrate, 40ml triethanolamine, 1.5 ml nonionic surfactant, 0.5 g vanillin. Stir the weighed sodium hydroxide and zinc oxide evenly, add 1 / 5 of the total volume of the plating solution in distilled water to dissolve, and stir to dissolve until the solution is clear and transparent, then dilute to 1 / 3 of the total volume, this solution is 1 No. solution; then dissolve the weighed nickel sulfate hexahydrate, potassium sodium tartrate, and sodium citrate respectively, then mix and stir thoroughly, then add the weighed ethylenediamine, tetraethylenepentamine and triethanolamine, stir and mix Evenly, this solution is No. 2 solution. Finally, slowly add No. 2 solution into No. 1 solution, stir while adding, the...

Embodiment 3

[0046] (1) Preparation of alkaline zinc-nickel alloy plating solution: First, weigh 10g of zinc oxide, 80g of sodium hydroxide, 15g of nickel sulfate hexahydrate, 15ml of ethylenediamine, 10ml of tetraethylenepentamine, 30g of potassium sodium tartrate, and 10g of lemon sodium nitrite, 40ml triethanolamine, 1.5 ml nonionic surfactant, 0.5 g vanillin. Stir the weighed sodium hydroxide and zinc oxide evenly, add 1 / 5 of the total volume of the plating solution in distilled water to dissolve, and stir to dissolve until the solution is clear and transparent, then dilute to 1 / 3 of the total volume, this solution is 1 No. solution; then dissolve the weighed nickel sulfate hexahydrate, potassium sodium tartrate, and sodium citrate respectively, then mix and stir thoroughly, then add the weighed ethylenediamine, tetraethylenepentamine and triethanolamine, stir and mix Evenly, this solution is No. 2 solution. Finally, slowly add No. 2 solution into No. 1 solution, stir while adding, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com