Sterilization laundry detergent containing epsilon-polylysine

A technology of polylysine and laundry detergent, applied in the directions of detergent compounding agent, detergent composition, organic detergent composition, etc., can solve problems such as endangering human health, irritating skin, etc., and achieve high safety and detergency. Strong antibacterial and bactericidal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

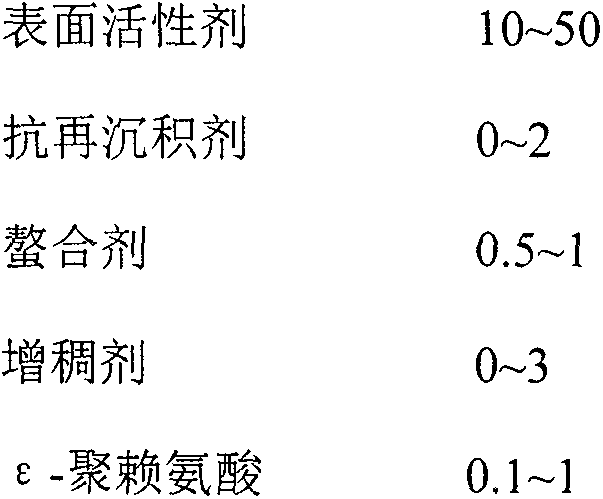

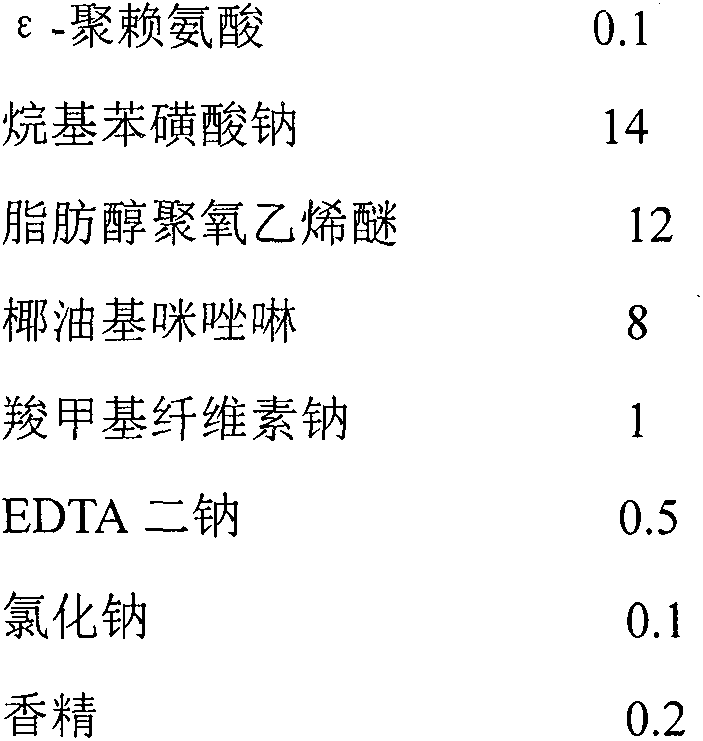

[0018] A bactericidal laundry detergent containing ε-polylysine, comprising the following components (in mass percent):

[0019]

[0020]

[0021] Prepare the laundry detergent according to the following steps: (1) Add accurately measured sodium alkylbenzene sulfonate, fatty alcohol polyoxyethylene ether and deionized water into the stirring tank, heat up to 60° C., and stir until completely dissolved; (2) ) Slowly add accurately measured coco-based imidazoline and ε-polylysine, stir until they are completely dissolved, cool, observe the reaction kettle until a transparent and uniform solution is completely formed; (3) Add other additives, after all dissolve Standing for defoaming, the bactericidal laundry detergent containing ε-polylysine is prepared. Through comparison test with commercially available conventional sterilizing laundry detergent containing p-chlorine m-xylenol, the laundry detergent of Example 1 has strong detergency and can kill more than 99.99% of micr...

Embodiment 2

[0025] A bactericidal laundry detergent containing ε-polylysine, comprising the following components (in mass percent):

[0026]

[0027] Prepare the laundry detergent according to the following steps: (1) Add accurately measured fatty alcohol polyoxyethylene ether sodium sulfate and deionized water into the stirring tank, heat up to 60°C, and stir until completely dissolved: (2) Slowly add accurately measured Sorbitan alkyl ester and ε-polylysine, stir until they are completely dissolved, cool, observe the reaction kettle until a transparent and uniform solution is completely formed; (3) add other additives, and let stand to eliminate Bubble, that is to prepare a bactericidal laundry detergent containing ε-polylysine. The laundry detergent has strong detergency and can kill more than 99.99% of microorganisms. After washing, the clothes have no smell of chemical fungicides and have a fresh smell.

[0028] Table 2 washing effect

[0029]

[0030]

Embodiment 3

[0032] A bactericidal laundry detergent containing ε-polylysine, comprising the following components (in mass percent):

[0033]

[0034] Prepare the laundry detergent according to the following steps: (1) Add accurately measured sodium alkylbenzene sulfonate, cocoic acid diethanolamide, cocamidopropyl betaine and deionized water into the stirring tank, and heat up to 60°C , stir until completely dissolved; (2) slowly add accurately measured ε-polylysine, stir until it is completely dissolved, cool, observe the reaction kettle until a transparent and uniform solution is completely formed; (3) add other additives, all After dissolving, let it stand for defoaming, and then prepare the ε-polylysine-containing bactericidal laundry liquid. The laundry detergent has strong detergency and can kill more than 99.99% of microorganisms. After washing, the clothes have no smell of chemical fungicides and have a fresh smell.

[0035] Table 3 washing effect

[0036]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com