Hydrocarbon-resistant indoor thin fireproofing coating for steel structures

A fire-resistant coating and thin-coating technology, applied in fire-resistant coatings, epoxy resin coatings, coatings, etc., can solve the problems of poor adhesion, easy peeling, poor fire-proof and heat-insulation effect, etc. Good acidity and alkalinity, good foaming effect

Inactive Publication Date: 2013-12-18

王海辉

View PDF3 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] The purpose of the present invention is to overcome the deficiencies of the prior art, and to design a hydrocarbon-resistant indoor thin-coated steel structure fireproof coating, which solves the ubiquitous problems of thin-coated steel structure fireproof coatings that are easy to fall off in the event of a fire, poor adhesion, and fireproof. The problem of poor insulation

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

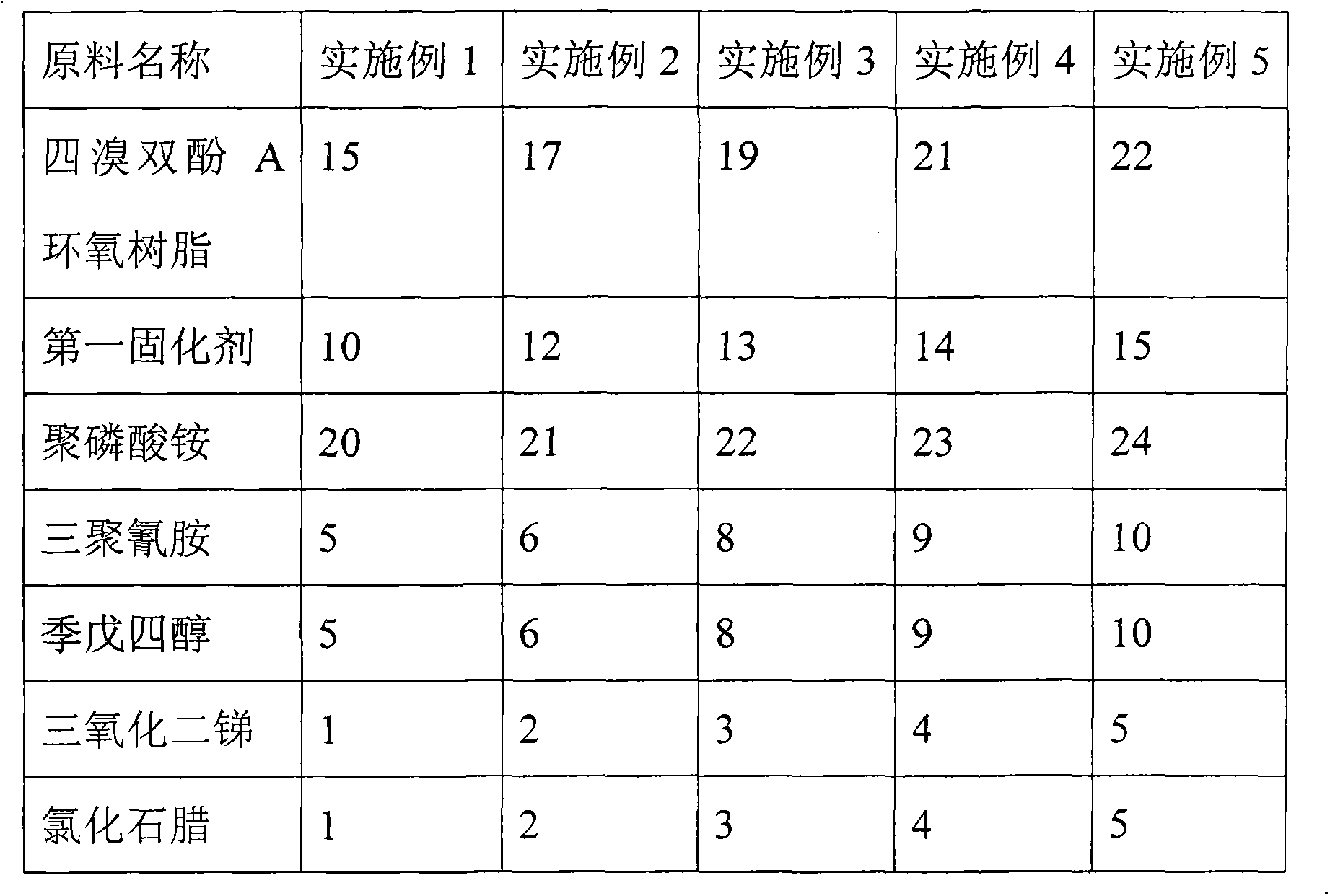

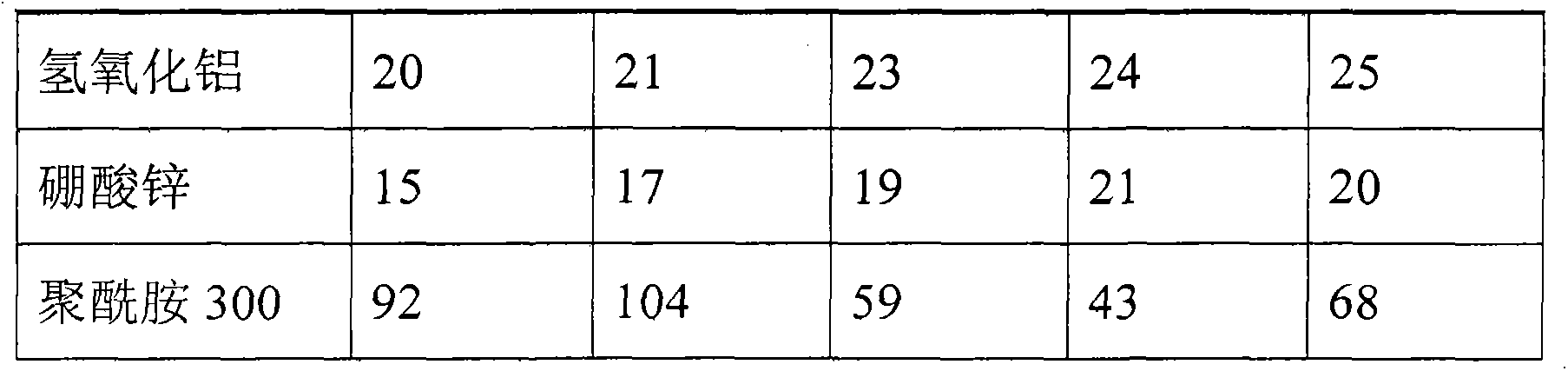

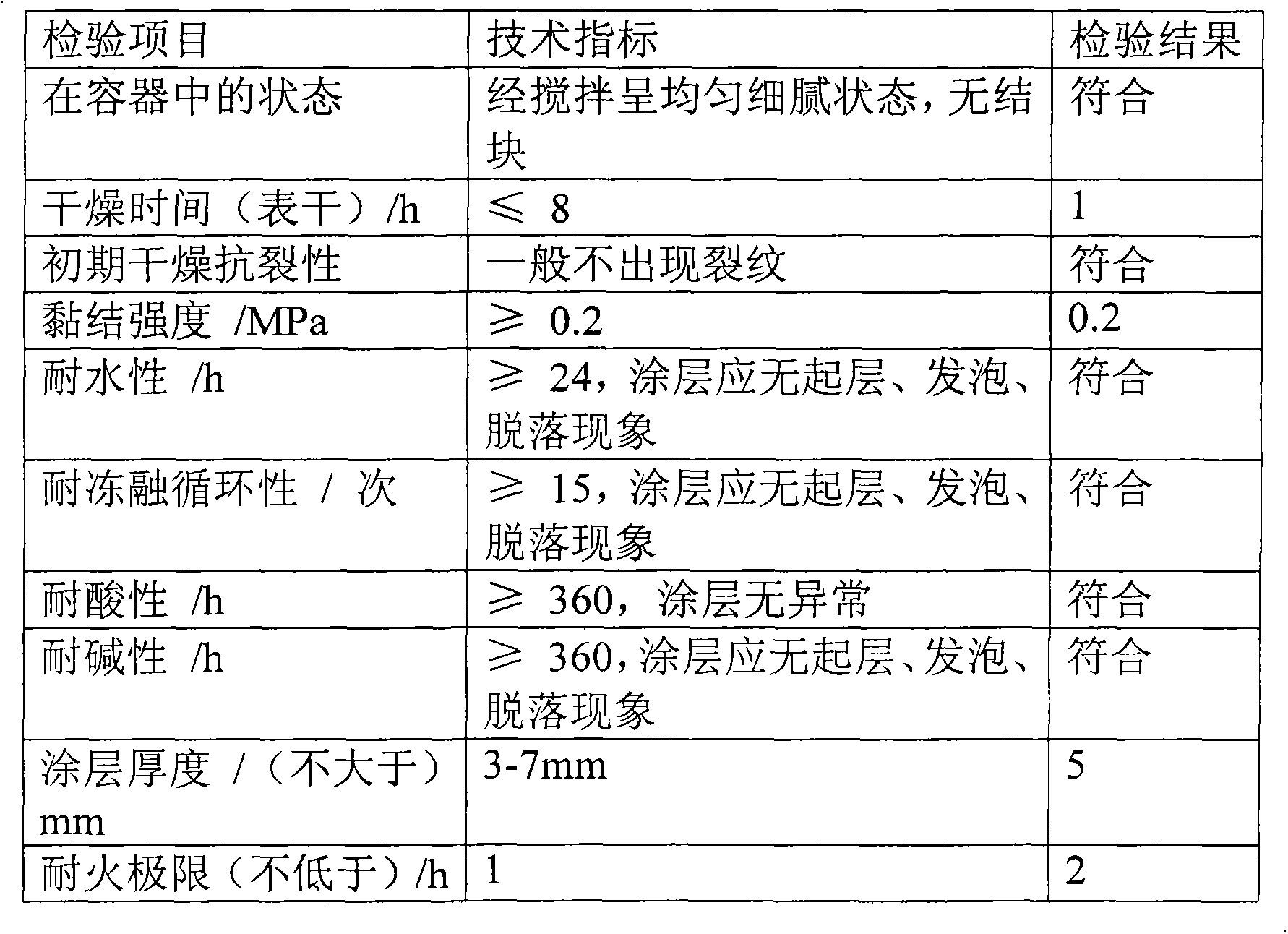

The invention discloses a hydrocarbon-resistant indoor thin fireproofing coating for steel structures, aiming at solving the problems of general thin fireproofing coatings for steel structures which are easy to peel off in case of fire disaster, poor in adhesion performance, and poor in fireproofing and heat insulation effects. The technical scheme is as follows: the fireproofing coating is prepared from a component A: TBA type epoxy resin fireproofing coating, and a component B, namely polyamide 300 curing agent, at (1-3):1 in parts by mass, wherein the component A, namely TBA type epoxy resin fireproofing coating, consists of the following materials in parts by weight: 15-22 parts of TBBP-A epoxy resin, 10-15 parts of first curing agent, 20-24 parts of ammonium polyphosphate, 5-10 parts of melamine, 5-10 parts of pentaerythritol, 1-5 parts of antimonous oxide, 1-5 parts of chlorinated paraffin, 20-25 parts of aluminum hydroxide and 15-20 parts of zinc borate. The fireproofing coating has the advantages of good foaming effect, massive generation of carbide, little smoke, strong adhesion force, good acid-base resistance property and good fireproofing and heat insulation effects.

Description

technical field [0001] The invention belongs to the technical field of fireproof coatings, and relates to a hydrocarbon-resistant indoor thin-coated steel structure fireproof coating, in particular to a hydrocarbon-resistant indoor thin-coated steel structure fireproof coating with good adhesion and good fireproof and heat insulation effects. Background technique [0002] The frames of modern large-scale buildings and petrochemical facilities mostly use steel structures. However, the thermal conductivity of steel is generally 52W / (m·K). The yield strength drops sharply to about 40% of the normal temperature state and loses its bearing capacity, so fire protection must be carried out on the steel structure. It is undoubtedly one of the most economical, convenient and effective methods to protect steel structures with intumescent fire retardant coatings. The intumescent fireproof coating is sprayed on the steel surface, and when the coating is exposed to fire, it foams and ex...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C09D163/02C09D7/12C09D5/18

Inventor 王海辉

Owner 王海辉

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com