Anti-infection material for intrauterine contraceptive device and preparation method of anti-infection material

An IUD and anti-infection technology, which is applied in the fields of medical science and surgery, can solve the problems that polymer material parts are easy to adhere to bacteria, polymer parts do not have anti-infection, and form infection sources, so as to reduce the phenomenon of uterine inflammation and Its secretion, improve anti-infection performance, improve the effect of tissue compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

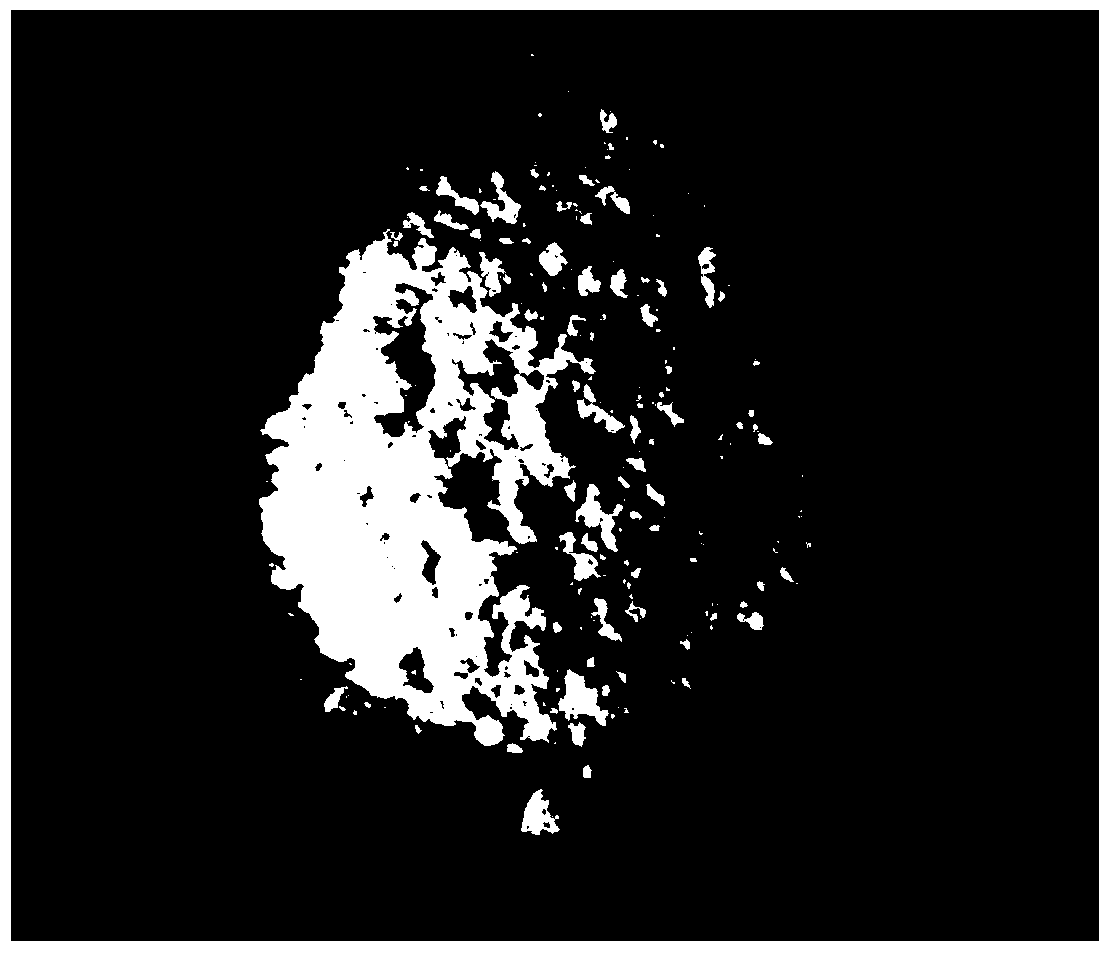

[0031] Weigh 1.0kg of chitosan with a degree of deacetylation of 50%, dissolve it in a dilute hydrochloric acid solution with a pH of 1.0, make it fully dissolved, then add 0.01kg of anhydrous copper sulfate, stir it fully to make it fully dissolve in the shell Form chitosan complex in polysaccharide hydrochloric acid solution, then add 1.0mol / L sodium hydroxide solution to precipitate chitosan complex, wash with deionized water, dry under reduced pressure or hot air, pulverize, and finally form a powder Chitosan complexes such as figure 1 shown.

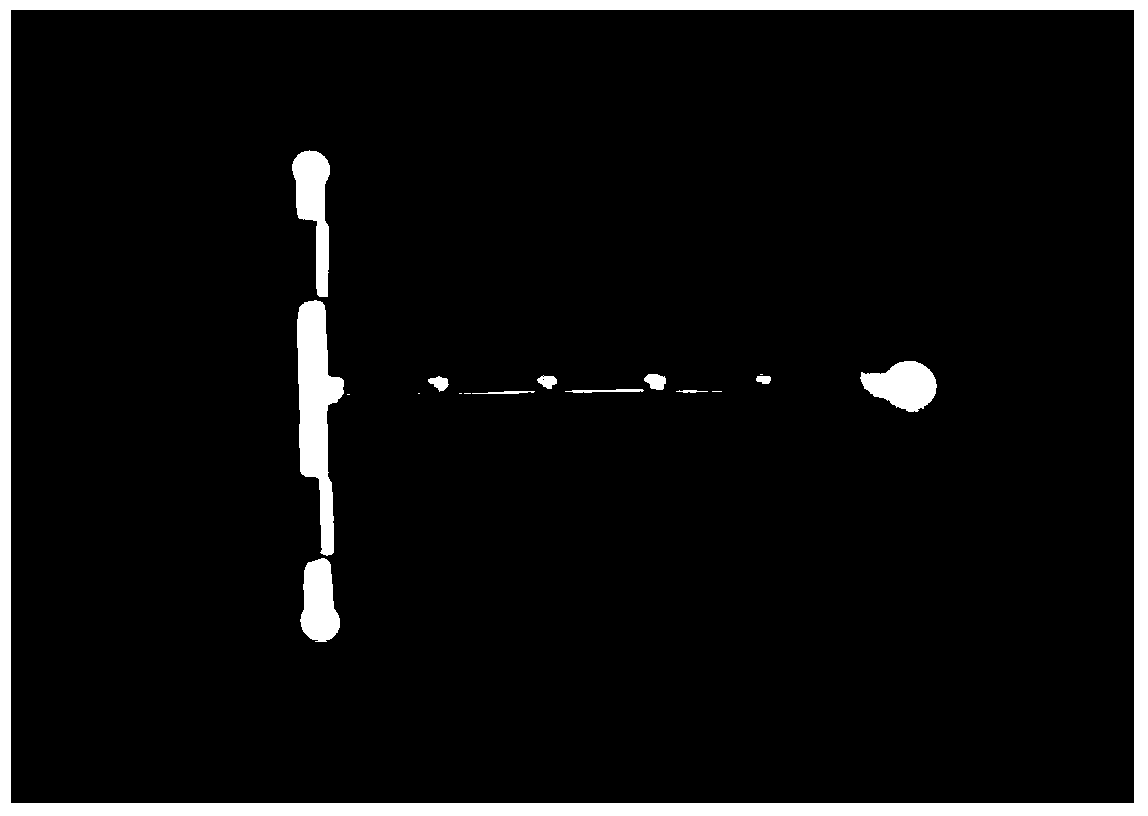

[0032] 0.6kg of the above-mentioned powdered chitosan compound and 1.0kg of low-density polyethylene are physically mixed, and the mixture is melt-blended through a twin-screw extruder to prepare a uniformly mixed low-density polyethylene material containing the chitosan compound , and then injection molded into T-shaped polymer parts for TCuIUD, such as figure 2 As shown, the polymer component has excellent antibacterial propert...

Embodiment 2

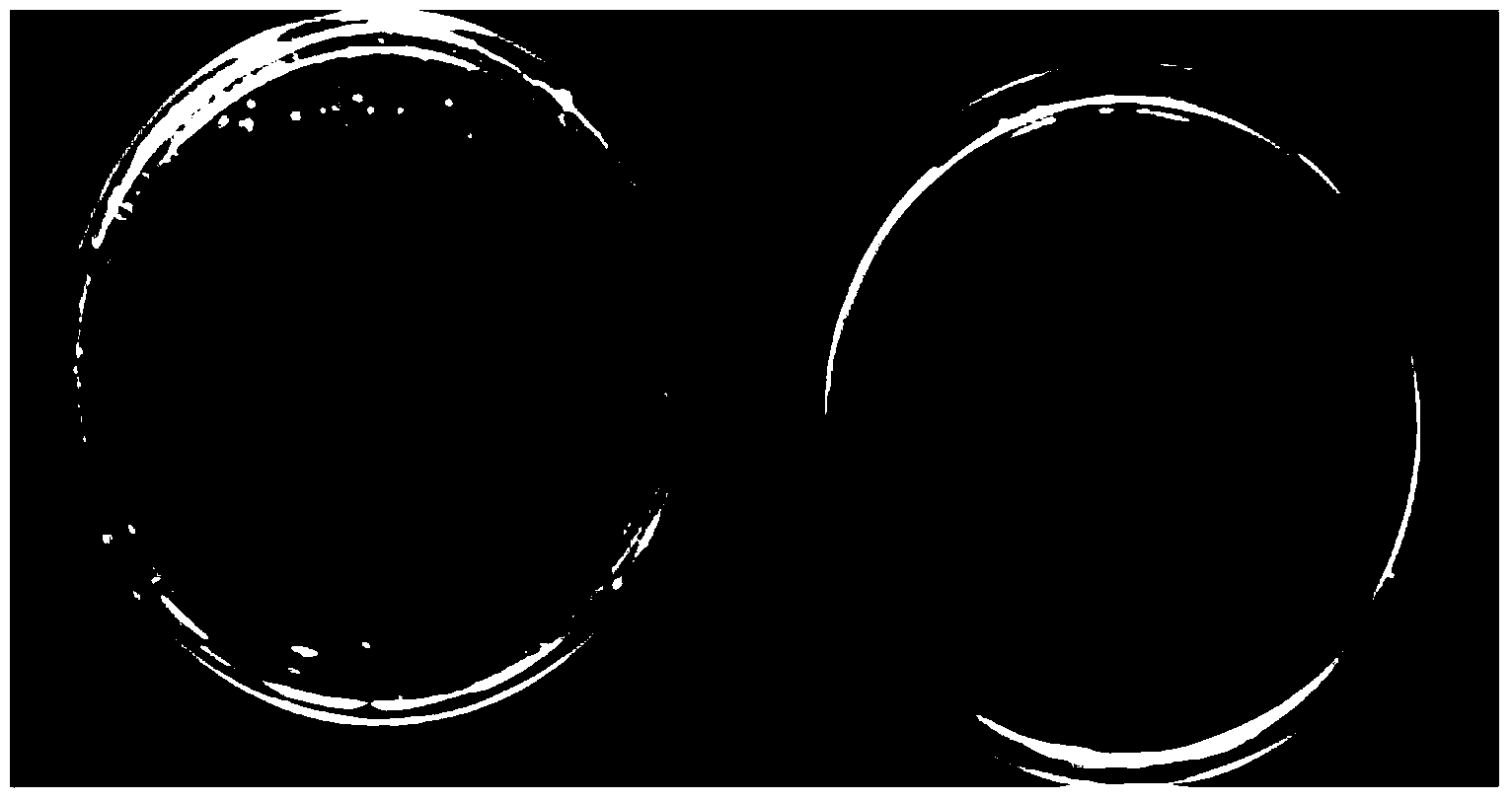

[0034] Weigh 1.0kg of chitosan with a degree of deacetylation of 100%, dissolve it in a dilute hydrochloric acid solution with a pH of 5.0, make it fully dissolved, then add 2.0kg of anhydrous copper sulfate, stir it fully to make it fully dissolve in the shell Chitosan complexes are formed in the polysaccharide hydrochloric acid solution, and the chitosan complexes are obtained after solution extrusion molding, no problem washing with 1.0mol / L sodium hydroxide solution, deionized water washing, and shearing, and decompression Or hot air drying, and finally form a fibrous chitosan complex, such as Figure 4 shown.

[0035] 1.0kg of the above-mentioned fibrous chitosan compound and 0.7kg of low-density polyethylene are physically mixed, and the mixture is melt-blended through a twin-screw extruder to prepare a uniformly mixed low-density polyethylene containing chitosan compound The material is then injection molded into a T-shaped polymer part for TCuIUD. The polymer part has...

Embodiment 3

[0037] Weigh 1.0kg of chitosan with a degree of deacetylation of 50%, dissolve it in a dilute hydrochloric acid solution with a pH of 5.0, make it fully dissolved, then add 0.5kg of silver nitrate, stir it fully to make it fully dissolve in chitosan Form chitosan complex in hydrochloric acid solution, then add 1.0mol / L sodium hydroxide solution to precipitate chitosan complex, wash with deionized water, dry and pulverize under reduced pressure or hot air, and finally form powdered chitosan sugar complexes.

[0038]0.01kg of the above powdered chitosan compound and 1.0kg of low-density polyethylene are physically mixed, and the mixture is melt-blended through a twin-screw extruder to prepare a uniformly mixed low-density polyethylene material containing the chitosan compound , and then injection molded into a T-shaped polymer part for TCuIUD. The polymer part has excellent antibacterial properties, and the antibacterial rate against Candida albicans reaches 99%, thereby improvi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com