Flat type speaker having vibration-lead plate of PCB voice coil plates

A flat-panel speaker and guide plate technology, which is applied in the fixing/tightening of electrostatic transducer speakers, sensors, and diaphragms, can solve the problems of small bonding area, limitation of speaker vibration energy conduction, disconnection, etc., to shorten the project. , Solve the effect of product quality decline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

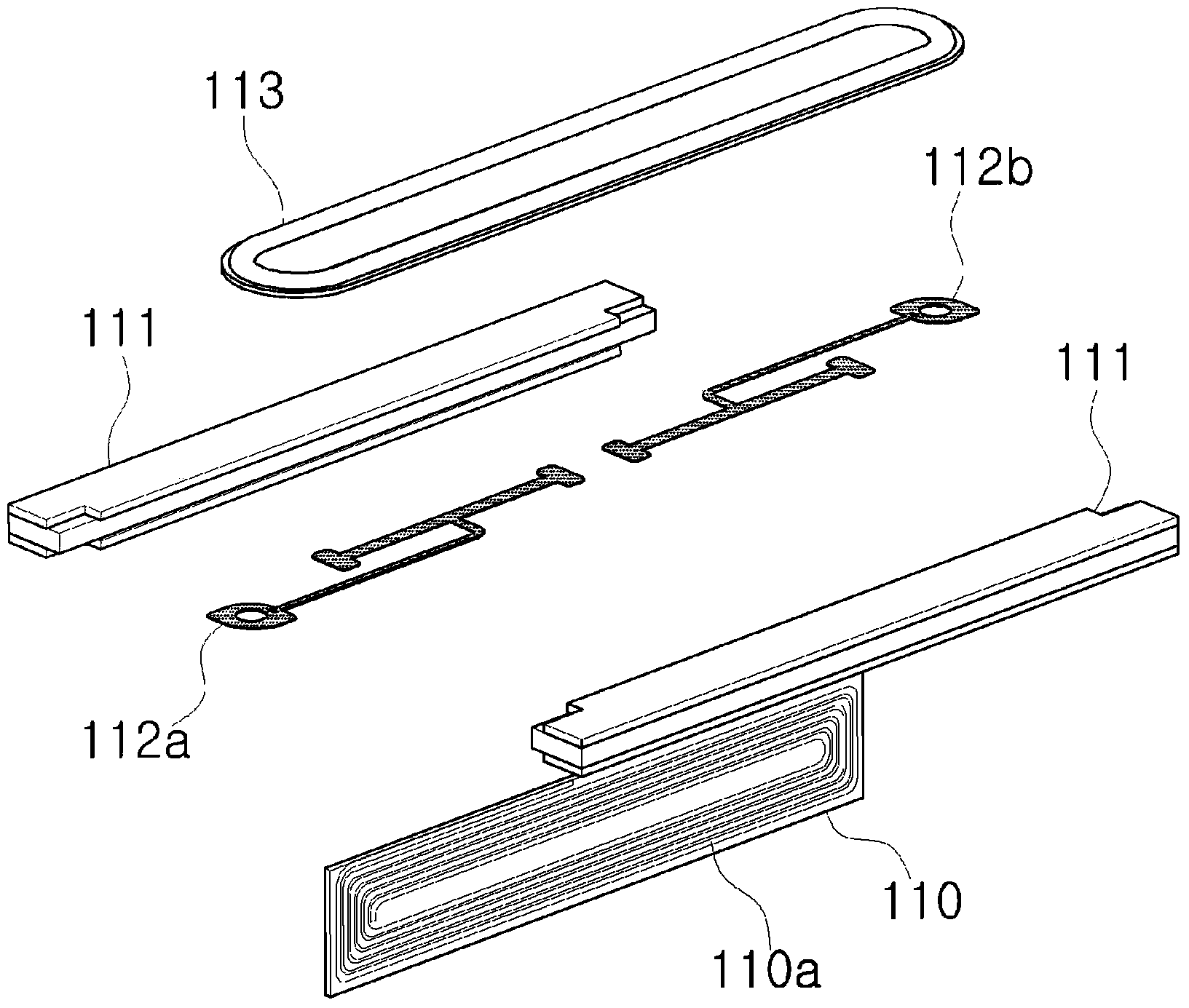

[0037] Next, with reference to the accompanying drawings, the structure and effects of the flat panel speaker with the vibration-guiding metal plate of the PCB voice coil board of the present invention will be described in detail.

[0038] figure 1 It is an oblique view of the panel speaker with the vibration guide plate of the PCB voice coil board according to the present invention. figure 2 It is an exploded oblique view of a panel speaker having a vibration-guiding metal plate of a PCB voice coil plate according to the present invention.

[0039] Such as figure 1 Shown, the present invention has the panel loudspeaker of the vibration guide disk of PCB voice coil plate to be made of following several parts: voice coil plate (110), it is printed with the PCB (PRINT CIRCUIT BOARD: printed circuit board) form of tracking form pattern The voice coil (110a) is pattern printed; a pair of magnetic bodies (111) are at a certain interval on the left and right sides of the voice co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com