Array substrate, manufacturing method of array substrate, and display device

An array substrate and electrode layer technology, applied in the field of organic electroluminescent display, can solve the problems of high manufacturing process and difficulty, deviation of luminous color, limited types of materials, etc., and achieve the goal of improving luminous efficiency, enhancing luminous efficiency, and improving light extraction efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

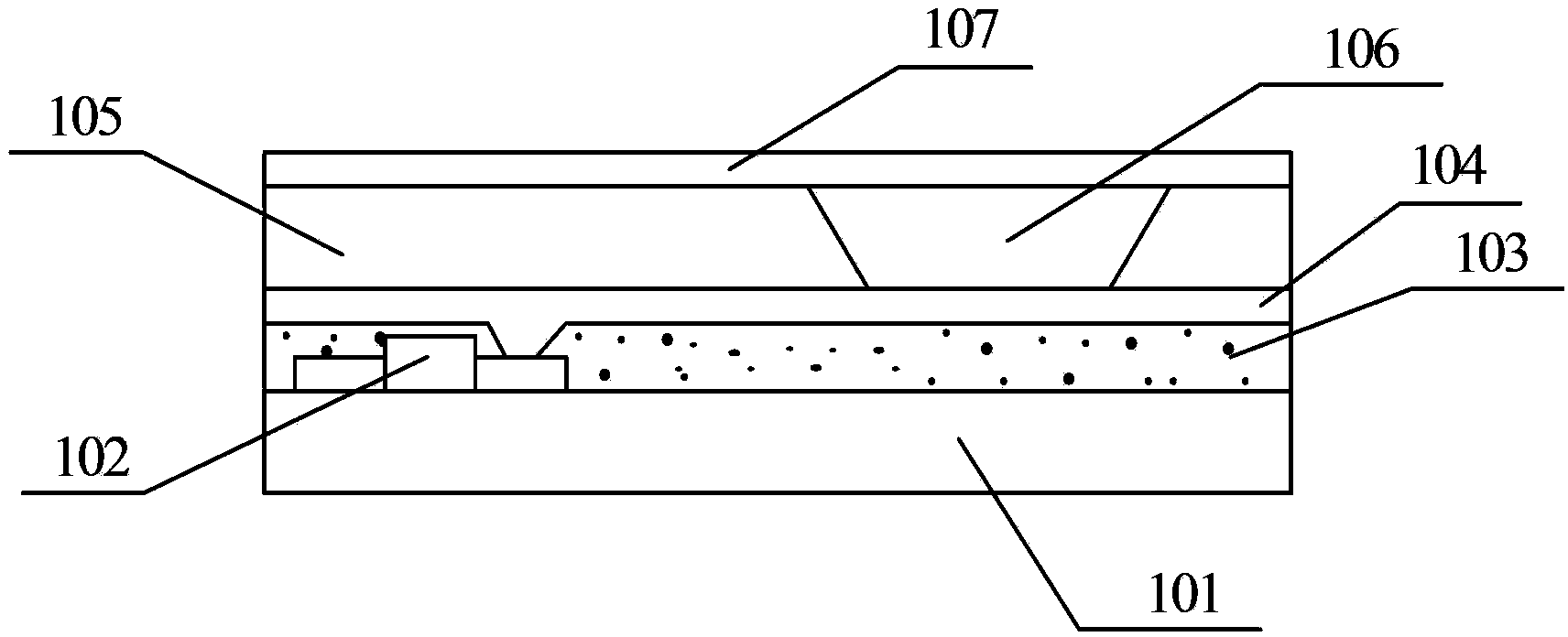

[0033] combine image 3 , this embodiment provides an array substrate, which includes an organic electroluminescent device, and the organic electroluminescent device includes: a first electrode layer 104, a second electrode layer 107, and The light-emitting layer 106 between 107, wherein the first electrode layer 104 is a transparent electrode layer, which is disposed on the planarization layer 103 doped with metal micro-nano particles q.

[0034] The planarization layer 103 below the transparent electrode layer of the organic electroluminescent device of the array substrate in this embodiment is doped with metal micro-nano particles q, and the surface plasmon resonance effect of the metal micro-nano particles q is used to enhance organic electroluminescence The luminous efficiency of the device is improved, thereby enhancing the light extraction rate of the array substrate.

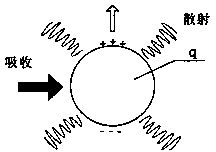

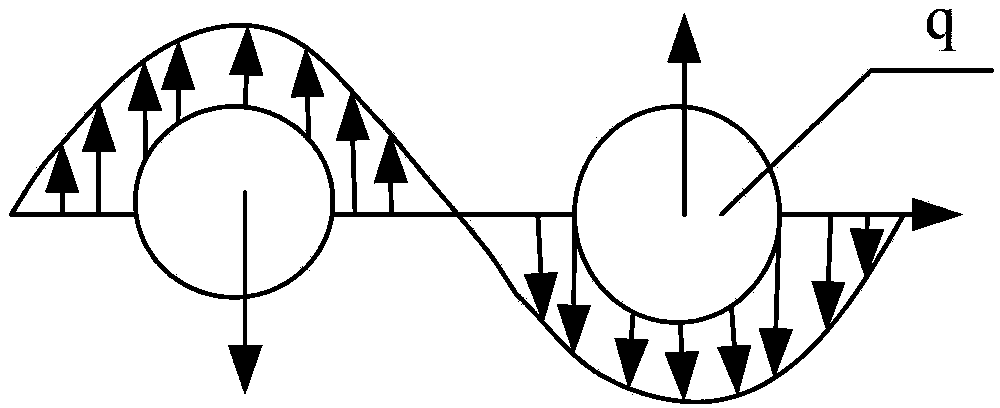

[0035] It should be noted that surface plasmons (surface plasmons; SPs) refer to the electron densit...

Embodiment 2

[0050] This embodiment provides a display device, which includes the array substrate described in Embodiment 1. The display device can be any device with a display function such as a mobile phone, a tablet computer, a television, a monitor, a notebook computer, a digital photo frame, a navigator, etc. product or part.

[0051] The display device of this embodiment has the array substrate in Embodiment 1, so it has better luminous efficiency and better visual effect.

[0052] Certainly, the display device of this embodiment may also include other conventional structures, such as a power supply unit, a display driving unit, and the like.

Embodiment 3

[0054] This embodiment provides a method for preparing an array substrate, which includes the following steps:

[0055] Step 1, forming a thin film transistor 102 on the substrate 101 through a patterning process. Wherein, the thin film transistor 102 may be a top-gate type or a bottom-gate type.

[0056] Of course, gate lines, data lines, etc. can also be formed at the same time, and the driving of the thin film transistors can be 2T1C, etc.

[0057] Step 2, forming a planarization layer 103 doped with metal micro-nano particles q on the substrate 101 on which the thin film transistor 102 is formed.

[0058] Wherein, the preparation of the planarization layer 103 doped with metal micro-nano particles q can adopt the following method;

[0059] Method 1, such as Figure 5 As shown in the schematic diagram of the structure, a first planarization layer 1031 is first deposited on the prepared thin film crystal substrate 101, and then a 2nm thick gold layer is plated on its surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com