High-sensitivity fiber grating voltage sensor

A voltage sensor, fiber grating technology, applied in the direction of measuring current/voltage, instrument, measuring electrical variables, etc., can solve problems such as limiting the test range, test result deviation, etc., to improve safety and stability, avoid errors, and improve sensitivity and stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

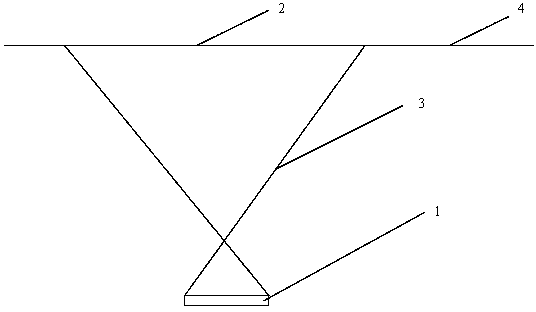

[0030] Such as figure 1 The fiber Bragg grating voltage sensor shown is composed of a piezoelectric ceramic 1, a fiber grating A2, a fork device 3 and a fiber Bragg grating B4, wherein the material of the fork device 3 is 4J36 iron-nickel alloy, and its structure is two X-shaped The metal rods placed across are hinged, and the hinged position is 1 / 6 of the total length of the metal rods from the bottom of the metal rods. The piezoelectric ceramic 1 is made of lead niobate piezoelectric ceramics, which is a cuboid, and the plane in contact with the fork-shaped device 3 There are two fixing holes on the top, and the bottom ends of the two metal rods of the fork device 3 are provided with embedded parts for extending into the fixing holes, which can be inserted into and nested in the fixing holes, and fixed with glue at the same time, the fiber grating A2 passes through the metal The fiber grating A2 is welded on the top of the fork device 3 with gold-tin solder, and the fiber Br...

Embodiment 2

[0035] Such as figure 1 The fiber Bragg grating voltage sensor shown is composed of a piezoelectric ceramic 1, a fiber grating A2, a fork device 3 and a fiber Bragg grating B4, wherein the material of the fork device 3 is 4J36 iron-nickel alloy, and its structure is two X-shaped The cross-placed metal rods are hinged, and the hinged position is 1 / 3 of the total length of the metal rod from the bottom end of the metal rod. The piezoelectric ceramic 1 is made of barium titanate piezoelectric ceramics, which is a cuboid. The plane in contact with the fork-shaped device 3 There are two fixing holes on the top, and the bottom ends of the two metal rods of the fork device 3 are provided with embedded parts for extending into the fixing holes, which can be inserted into and nested in the fixing holes, and fixed with glue at the same time, the fiber grating A2 passes through the metal The fiber grating A2 is welded on the top of the fork device 3 with gold-tin solder, and the fiber Br...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com