Multifunctional solid plunger tube oil well pump

A solid column and oil well pump technology is applied in the field of oil well pump and multifunctional solid plunger tubular well pump. The effect of preventing sediment clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

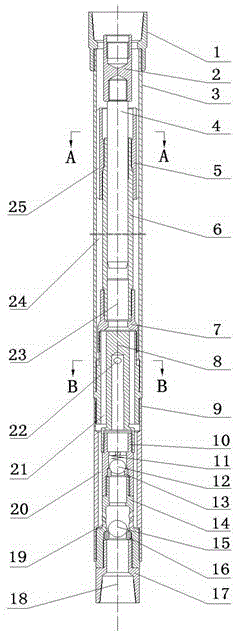

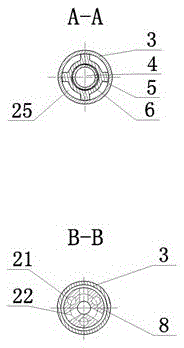

[0015] The structural principle and working principle of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0016] to combine figure 1 , figure 2 , the present invention includes an outer pump barrel 3 and an inner pump barrel 6, the upper end of the outer pump barrel 3 is connected to a tubing collar 1, a solid plunger assembly is installed in the inner pump barrel 6, and the top end of the solid plunger 4 is connected to a plunger joint 2, The upper end of the plunger joint 2 is connected to the sucker rod, and the working chamber 23 is formed between the bottom of the solid plunger 4 and the inner pump barrel 6. The pump barrel 3 is connected, and the upper oil outlet annulus 24 is formed between the inner pump barrel 6 and the outer pump barrel 3. The diversion joint 8 is connected to the backwash fixed valve cover 14 through the extension short pipe 9, and the backwash fixed valve cover 14 The lower liquid i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com