Full-section rectangular rapid heading machine with planet wheel driving Lello triangular cutterhead

A triangular and planetary gear technology, applied in mining equipment, earthwork drilling, tunnels, etc., can solve the problems of low section space utilization, manual correction, and inability to form at one time, so as to achieve high section space utilization, improve use efficiency, The effect of high numbers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

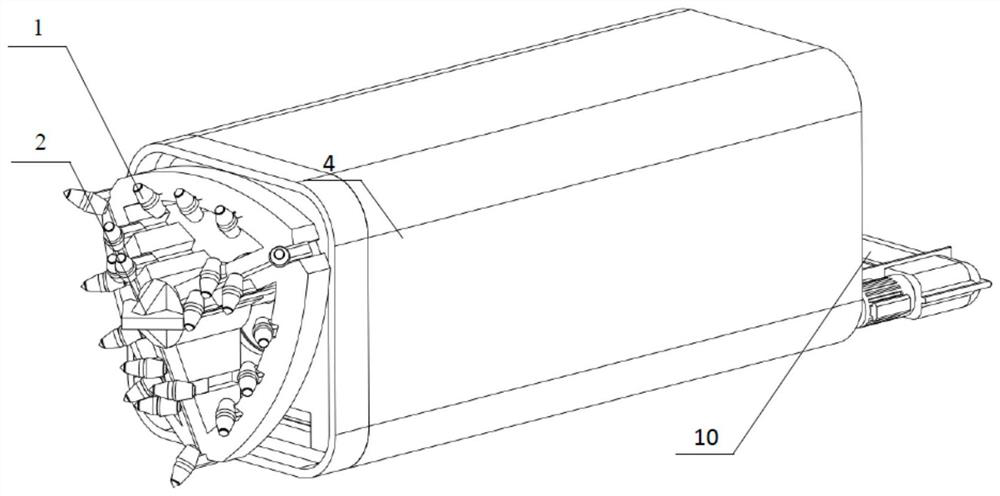

[0036] Such as figure 1 , 2 , 9-11, this example provides a full-section rectangular rapid roadheader with a planetary wheel driving a Lello triangular cutter head, including a driving device, a shield structure, and a cutter head, and a driving device is placed in a hollow inside the shield structure , the cutterhead is located in front of the shield body structure, the cutterhead is a conical structure with a Lelot triangle as the cross-section, and the driving device is used to drive the Lelot triangle cutterhead at the front of the shield structure to move, and the A cutting head 1 is arranged on the cutter head.

[0037] The drive device includes a power part and a transmission part, the power part is an electric motor, and the transmission part is a planetary gear box, and the planetary gear box includes a box body, a front end cover of the box body, an eccentric input shaft 73, a planetary gear shaft , internal gear, eccentric inner turntable, between the eccentric in...

example 2

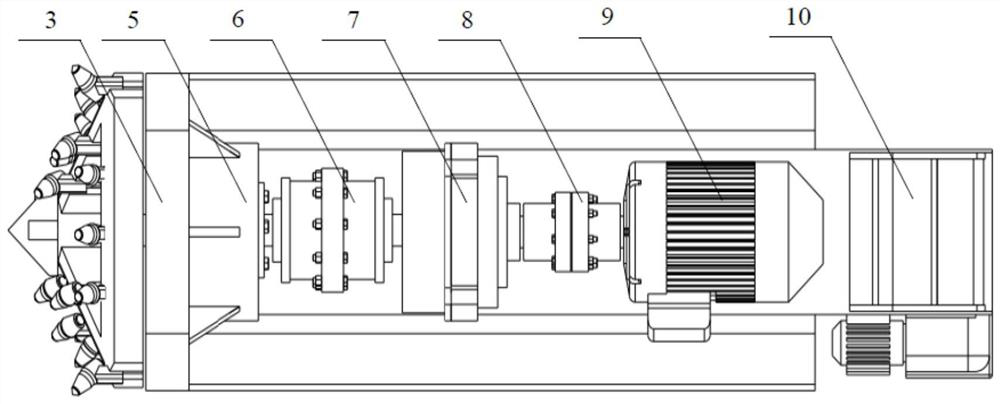

[0043] Such as Figure 3-5 As shown, the difference between this example and Embodiment 1 is that the cutter head of this example includes two cutter head structures, the two cutter head structures are arranged in a staggered front and rear, and each cutter head structure is connected to a driving device.

Embodiment 3

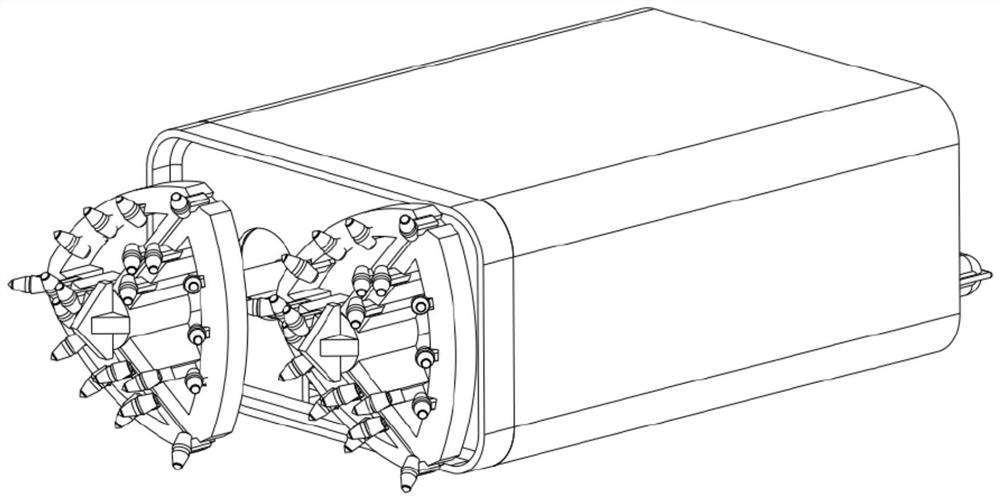

[0045] Such as Figure 6-8 As shown, the difference between this example and Embodiment 1 is that the cutter head of this example includes two two cutter head structures arranged side by side, and the two cutter head structures do not interfere with each other, and the steering of the two cutter head structures is opposite , each cutterhead structure is connected with a driving device; compared with the cutterhead of embodiment 1, the cutterhead of this example reduces the structure of the triangular edge part of the original cutterhead, and only the main frame is retained to make the double cutterhead turn On the contrary, it is arranged in parallel to avoid interference and carry out mining.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com