Linear transmission part

A technology of linear transmission and components, which is applied in transmission devices, belts/chains/gears, mechanical equipment, etc., can solve the problems of increasing the difficulty of installing spare parts, poor structural rationality, limited selection of spare parts, etc., and achieve less material consumption , The overall structure is compact and the section space utilization rate is high

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

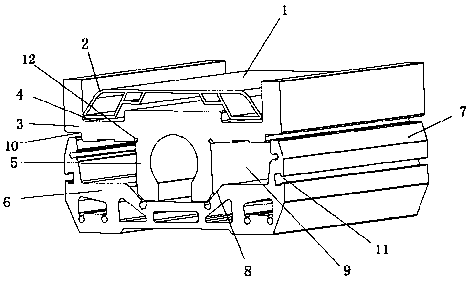

[0018] This embodiment provides a linear transmission component, including a base, a sliding table and a cover plate, and the sliding table is installed between the base and the cover plate. The cover plate is composed of a top plate 1 and a raised structure 2 arranged on both sides of the top plate 1; the slide table is a positive T-shaped structure, and a avoidance hole 12 is provided at the connection position between the horizontal part 3 and the vertical part 5 of the slide table, and the hole avoidance The setting of 12 facilitates the installation of parts and reduces the difficulty of installation. The upper surface of the horizontal part 3 of the slide table is provided with a first groove 4 that matches the raised structure 2, and the height of the first side of the first groove 4 close to the center of the horizontal part 3 is smaller than that of the first groove 4 away from the horizontal part. 3, the height of the second side away from the center of the transvers...

Embodiment 2

[0020] This embodiment is similar to Embodiment 1, and further, the lower surface of the transverse part 3 of the slide table is provided with a third groove 10 at a position corresponding to the top of the side wall 7, and the third groove 10 matches the top of the side wall 7 , the arrangement of the third groove 10 further improves the stability of the connection between the slide table and the base.

[0021] In addition, there is also a second protrusion inside the raised structure 2 on the cover plate, the second raised structure is connected to the raised structure 2, the size of the second raised structure is smaller than the size of the raised structure 2, and the raised structure 2 and the inside of the second protruding structure adopt a hollow design, which reduces the weight of the cover to a certain extent, saves materials and ensures its mechanical strength.

Embodiment 3

[0023] This embodiment is similar to Embodiment 1 or 2. Further, the cavity structure provided inside the support base 6 specifically includes a rectangular cavity structure, two triangular cavity structures and two trapezoidal cavity structures, and the rectangular cavity structure Located directly below the vertical part 5, the triangular cavity structure and the trapezoidal cavity structure are symmetrically distributed on both sides of the rectangular cavity structure, and the triangular cavity structure is located between the rectangular cavity structure and the trapezoidal cavity structure, and the trapezoidal cavity structure Mounting holes are provided around the structure. The supporting bottom plate 6 contains a plurality of cavity structures equipped with mounting holes, so that the base provides convenient space for the installation of components while ensuring the connection strength.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com