Post-cast strip construction and drainage method for base plate of basement

A technology of basement floor and post-pouring belt, which is applied in the field of engineering construction, can solve the problems of cement slurry loss, high groundwater pressure, and poor water permeability, and achieve the effects of reducing the probability of leakage, simple construction, and good seepage and drainage effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

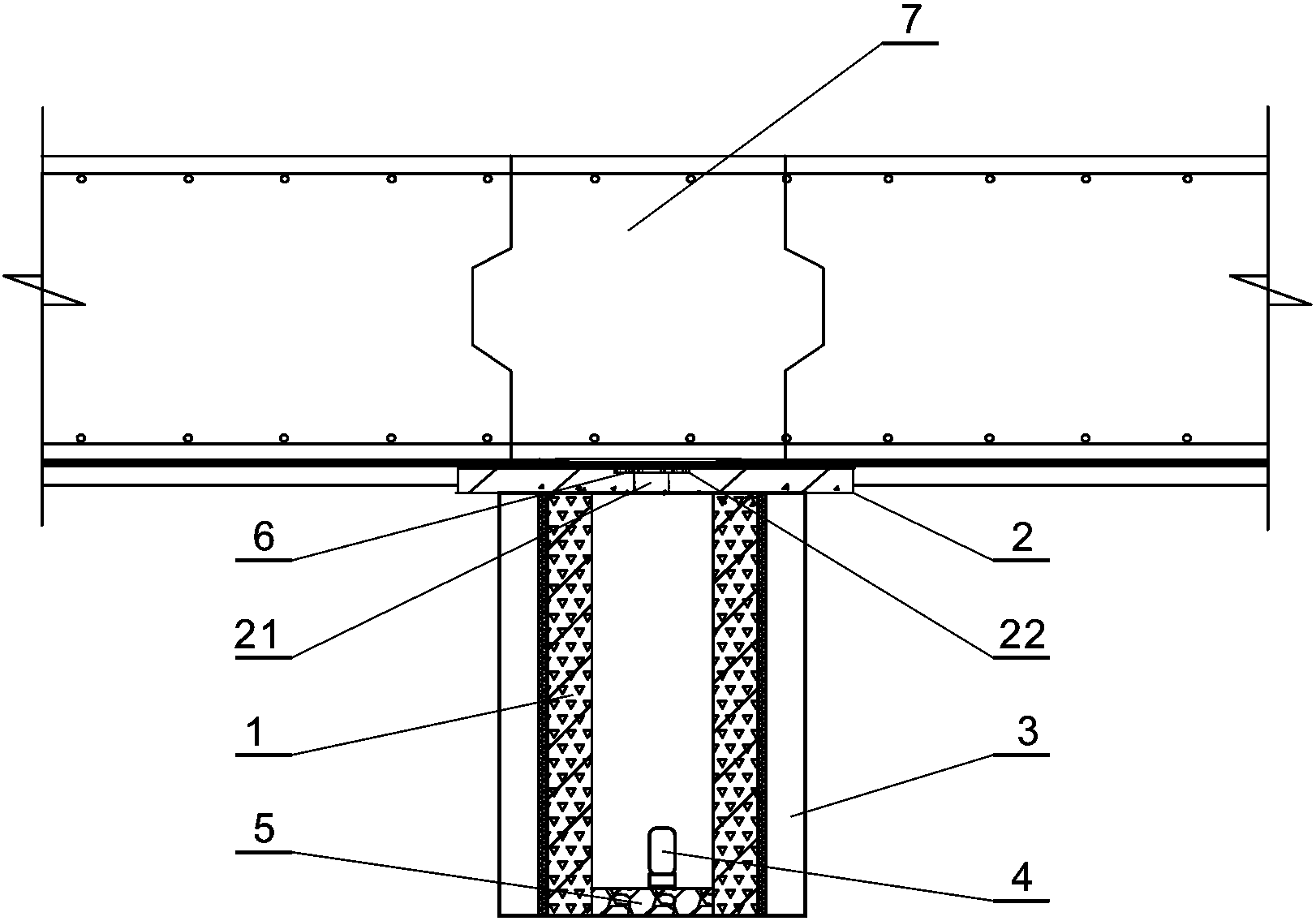

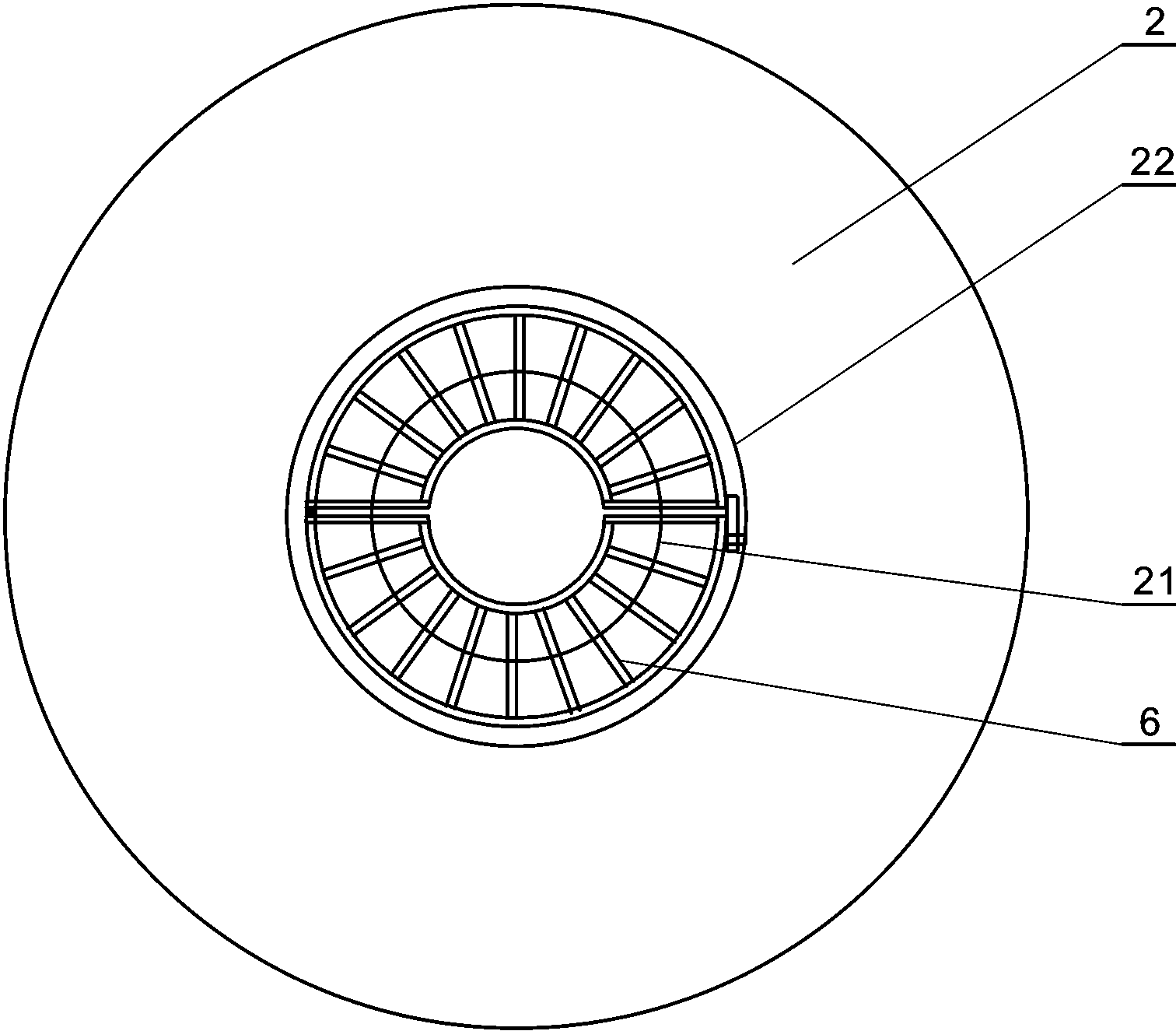

[0021] refer to figure 1 , figure 2 , the concrete implementation steps of the present invention are as follows:

[0022] a), prefabricated permeable pipe and cover plate

[0023] The prefabricated permeable pipe 1 is made of sand-free and permeable concrete. The outer diameter of the permeable pipe is Φ500mm; the wall thickness of the permeable pipe is 40mm; the height of the permeable pipe is 1500 mm; the outer wall of the permeable pipe 1 is wrapped with gauze; The pipe 1 is wrapped with gauze on the outside of the permeable pipe 1 in order to keep the side wall of the permeable pipe 1 with good water permeability;

[0024] Prefabricated concrete cover plate 2, outer diameter of concrete cover plate: Φ1000mm; wall thickness of concrete cover plate: 60mm; pump outlet 21 and water grate concave platform 22 are set in the center of concrete cover plate, pump outlet diameter: Φ150mm; water grate concave platform Diameter: Φ300mm; Depth of water grate concave table: 15mm. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com