Preparation method of waterproof and moisture permeable fabric membrane, waterproof and moisture permeable fabric and preparation method of membrane

A waterproof and moisture-permeable film, waterproof and moisture-permeable technology, applied in chemical instruments and methods, non-woven fabrics, textiles and papermaking, etc., can solve the problems of expensive products, difficult processing, complicated processes, etc., and achieve low cost and high production efficiency. The effect of high efficiency and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] The invention provides a method for preparing a waterproof and moisture-permeable membrane, comprising the following steps:

[0045] Dissolving the hydrophobic polymer in the first spinning solvent to obtain a hydrophobic spinning solution;

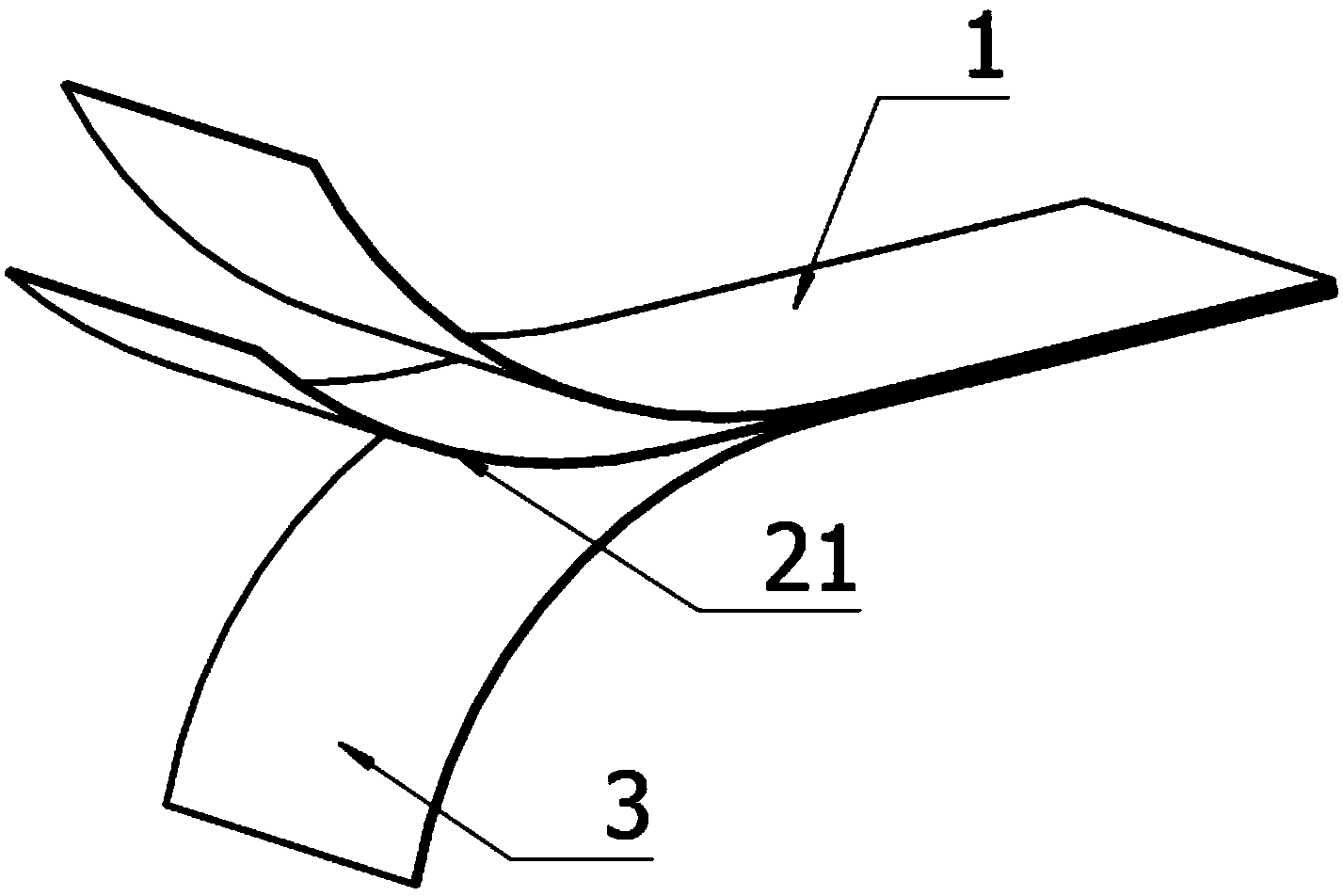

[0046] Carrying out the first electrospinning of the hydrophobic spinning solution to obtain a single-layer waterproof and moisture-permeable membrane;

[0047] or

[0048] Dissolving the hydrophilic polymer in the second spinning solvent to obtain a hydrophilic spinning solution;

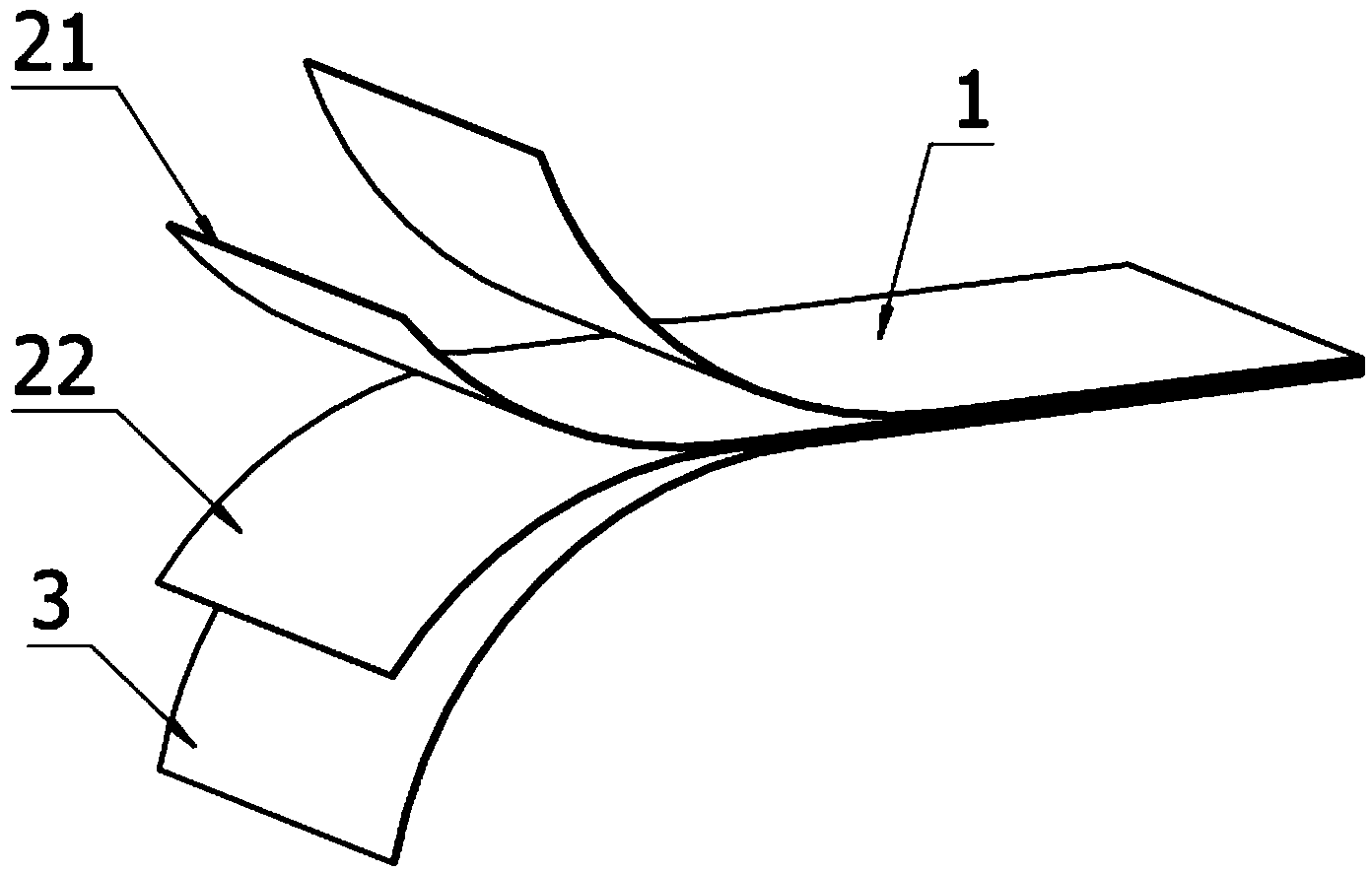

[0049] Carrying out the second electrospinning of the hydrophilic spinning solution to obtain a hydrophilic nanofiber membrane;

[0050] The single-layer waterproof and moisture-permeable membrane is combined with the hydrophilic nanofiber membrane to obtain a double-layer waterproof and moisture-permeable membrane.

[0051] In the invention, the polymer solution is electrostatically spun to obtain a waterproof and moisture-permeable membrane. The m...

Embodiment 1

[0095] Dissolve the polyvinylidene fluoride polymer in N,N-dimethylacetamide, stir the obtained first polymer solution in a constant temperature water bath at 55°C for 3 hours, and prepare the second polymer solution with a mass fraction of 20wt%. a spinning solution;

[0096] Dissolve polyimide in N,N-dimethylacetamide, stir the obtained second polymer solution in a constant temperature water bath at 55°C for 3 hours, and prepare the second spinning with a mass fraction of 20wt%. liquid;

[0097] The obtained first spinning solution and the second spinning solution are subjected to electrospinning, the spinning voltage is set to 30kV, the receiving distance is 15cm, and the spinning time is 1h, and the obtained first fiber and the second fiber are spun to obtain Single-layer waterproof and moisture-permeable membrane;

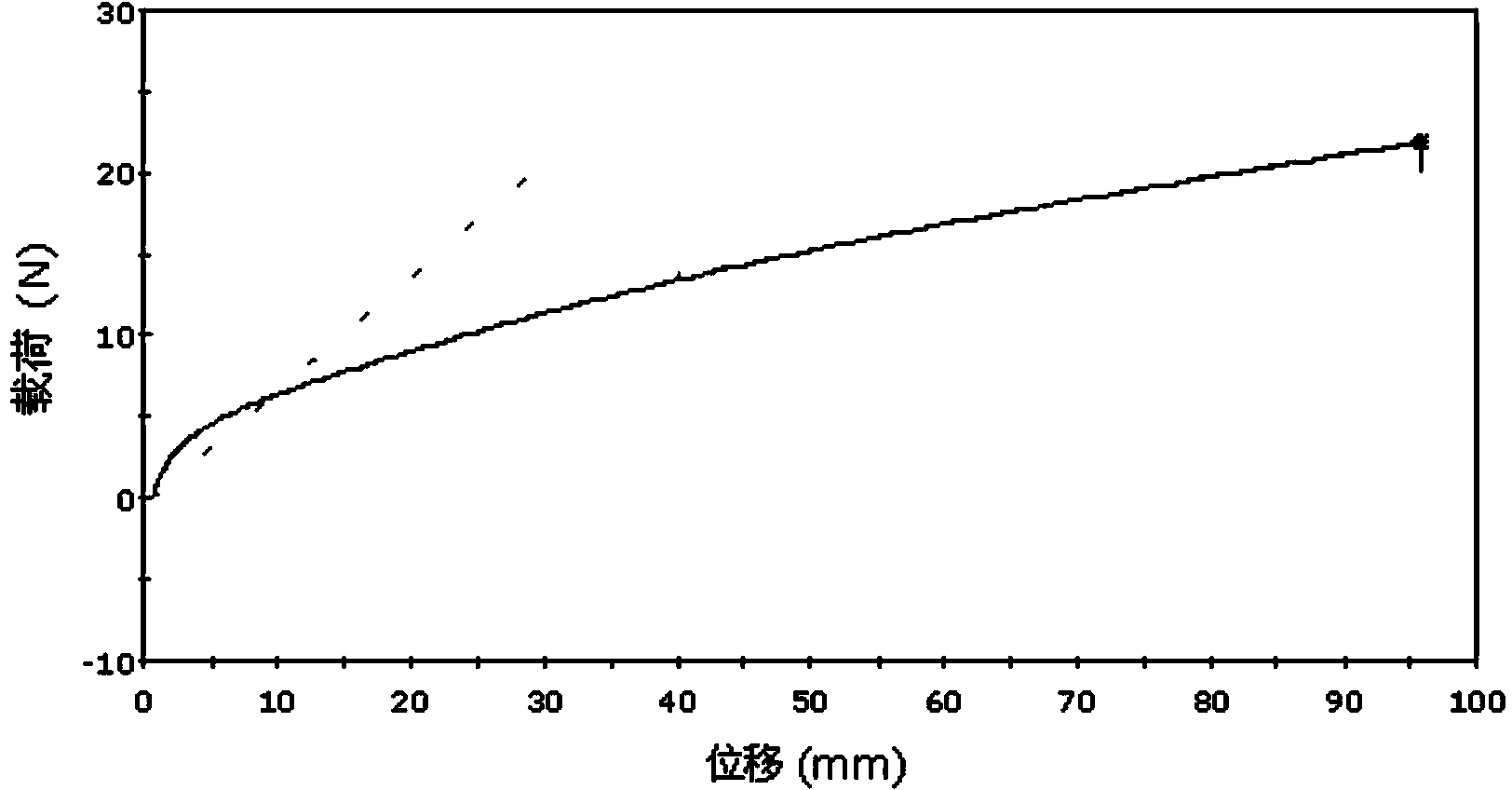

[0098] The average diameter of the fiber detected by the present invention is 326nm, the coefficient of variation CV is 6.73%, and the thickness of the fibe...

Embodiment 2

[0109] Dissolve the polyvinylidene fluoride polymer in N,N-dimethylacetamide, stir the obtained first polymer solution in a constant temperature water bath at 55°C for 4 hours, and prepare the first polymer solution with a mass fraction of 25wt%. a spinning solution;

[0110] Dissolve polytetrafluoroethylene in N,N-dimethylacetamide, stir the obtained second polymer solution in a constant temperature water bath at 55°C for 4 hours, and prepare a second spinning solution with a mass fraction of 25wt%. liquid;

[0111] The obtained first spinning solution and the second spinning solution are electrospun, the setting spinning voltage is 30kV, the receiving distance is 18cm, and the spinning time is 2 hours, and the obtained first fiber and the second fiber are spun A single-layer waterproof and moisture-permeable membrane is obtained;

[0112] The average diameter of the fiber detected by the present invention is 460nm, the coefficient of variation CV and 5.25%, and the thickne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Hydrostatic pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com