Preparation method of gluconic acid and glucaric acid

A technology of glucaric acid and gluconic acid, which is applied in the field of organic electrochemical synthesis, can solve the problems of product aldehyde and acid yield, regulation, and hindering new reactions, etc., so as to maintain continuous high efficiency, simple and stable process excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

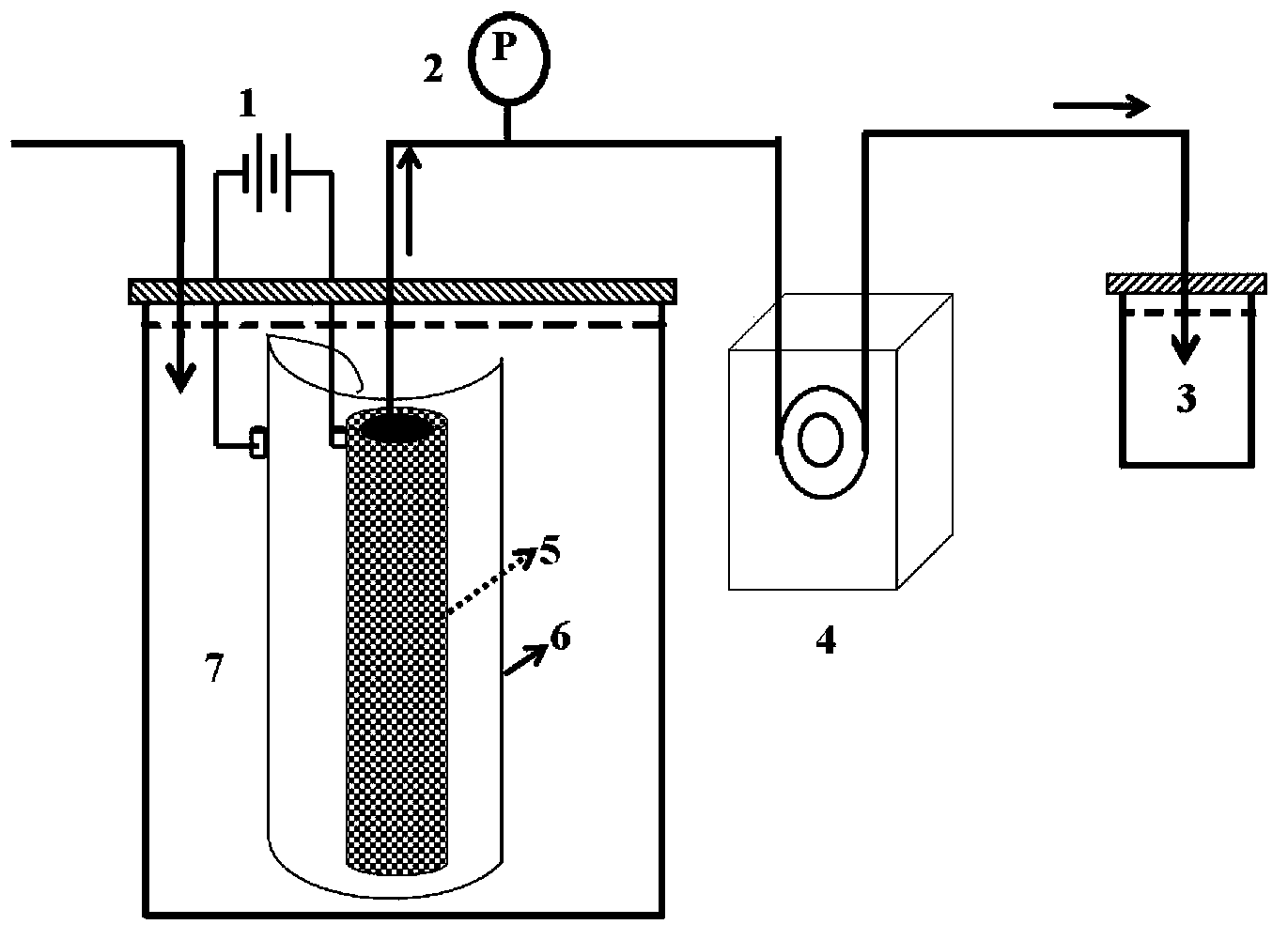

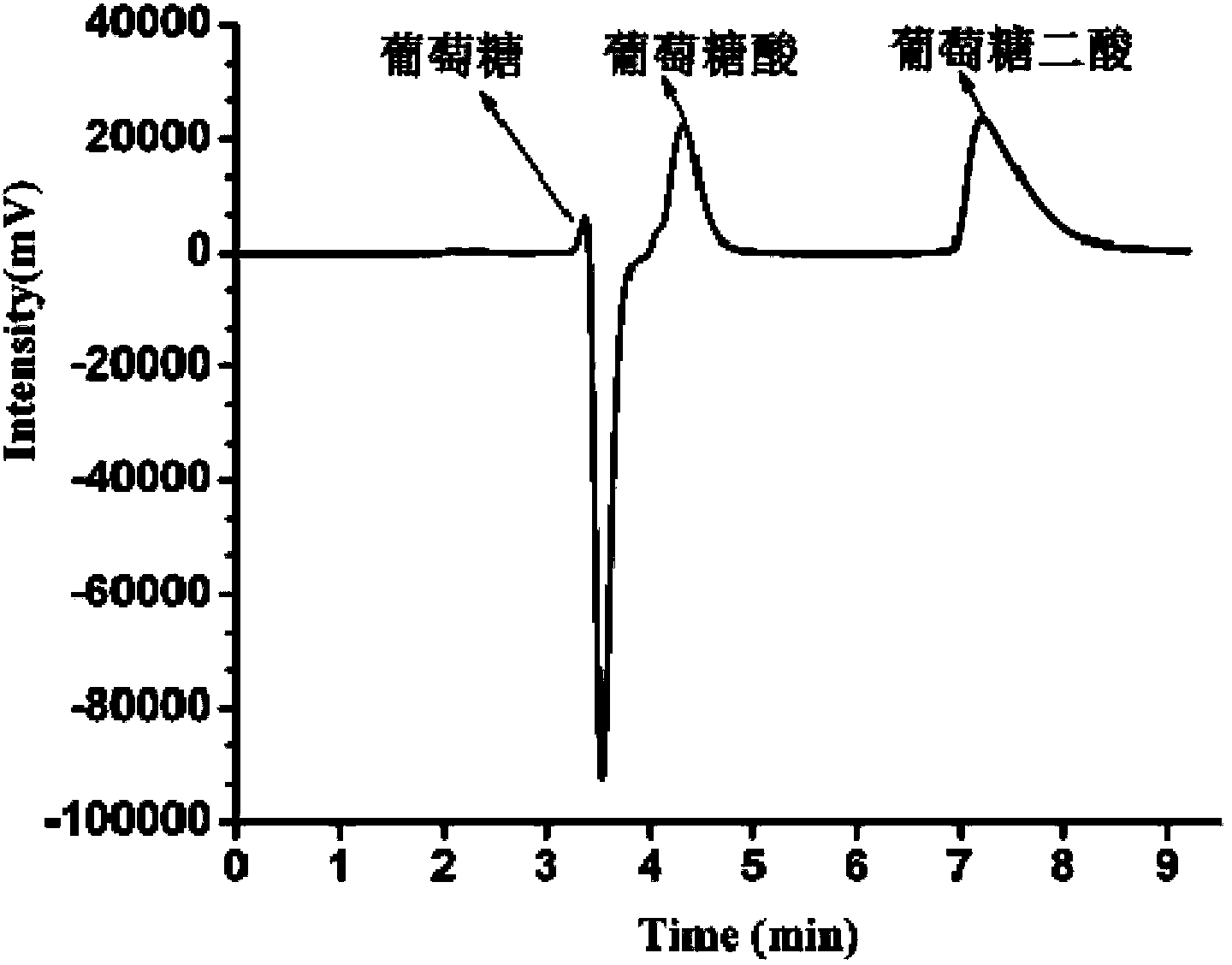

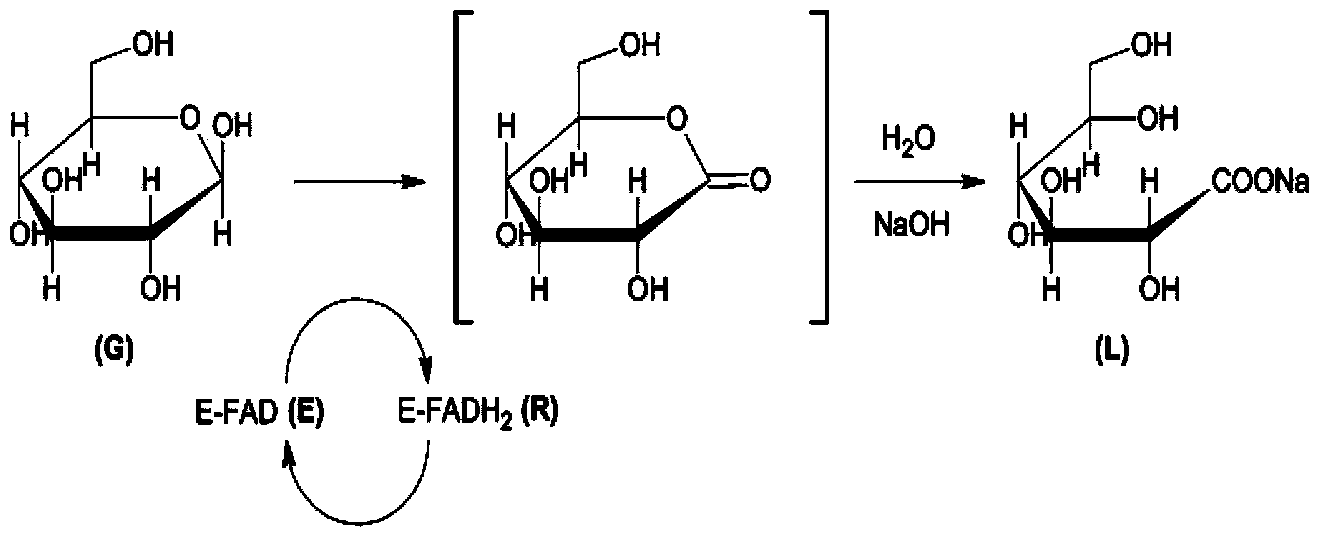

Embodiment 1

[0032] Nano TiO 2 The supported titanium-based electrocatalytic membrane is used as the anode, and the auxiliary electrode stainless steel is used as the cathode, which are respectively connected to a stabilized power supply via wires to form an electrocatalytic membrane reactor device. Prepare 50.5mmol / L glucose solution and place it in the membrane reactor at 0.1mmol / LH 2 SO 4 The solution is used as an electrolyte at room temperature and pressure, working voltage 2.8V, current density 3mA / cm 2 And membrane flux is 3.0L / m 2 ·Under the condition of h, the electrocatalytic membrane is used to catalyze the oxidation of glucose to prepare gluconic acid and glucaric acid. At the same time, the peristaltic pump is used to absorb the membrane permeate, and the target product obtained is separated from the reaction liquid in real time through the membrane osmosis. , The membrane permeate is separated and purified to obtain gluconic acid and glucaric acid products. The components of th...

Embodiment 2

[0042] Nano MnO 2 The supported titanium-based electrocatalytic membrane is used as the anode, and the auxiliary electrode stainless steel is used as the cathode to form an electrocatalytic membrane reactor device. Prepare 75.25mmol·L -1 The glucose solution is placed in the membrane reactor, with 0.1mmol / LNa 2 SO 4 The solution is used as the electrolyte, and the aqueous solution containing glucose and electrolyte is placed in the electrocatalytic membrane reactor at room temperature and pressure, working voltage 3.1V, current density 4mA / cm 2 And membrane flux is 2.0L / m 2 ·Under the condition of h, the electrocatalytic membrane is used to catalyze the oxidation of glucose to prepare gluconic acid and glucaric acid. At the same time, the peristaltic pump is used to absorb the membrane permeate, and the target product obtained is separated from the reaction liquid in real time through the membrane osmosis. , The membrane permeate is separated and purified to obtain gluconic acid ...

Embodiment 3

[0044] Nano WO 3 The supported titanium-based electrocatalytic membrane is used as the anode, and the auxiliary electrode stainless steel is used as the cathode to form an electrocatalytic membrane reactor device. Prepare 101mmol·L -1 The glucose solution is placed in a membrane reactor, with 0.1mmol / L NaCl solution as electrolyte, at room temperature and pressure, working voltage 3.5V, current density 6mA / cm 2 And membrane flux is 1L / m 2 ·Under the condition of h, the electrocatalytic membrane is used to catalyze the oxidation of glucose to prepare gluconic acid and glucaric acid. At the same time, the peristaltic pump is used to absorb the membrane permeate, and the target product obtained is separated from the reaction liquid in real time through the membrane osmosis. , The membrane permeate is separated and purified to obtain gluconic acid and glucaric acid products. The components of the permeate sample were analyzed by high performance liquid chromatography. Calculating u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com