Method for preparing aldehydes or acids by selectively performing catalytic oxidation on alcohols by electro-catalysis membrane

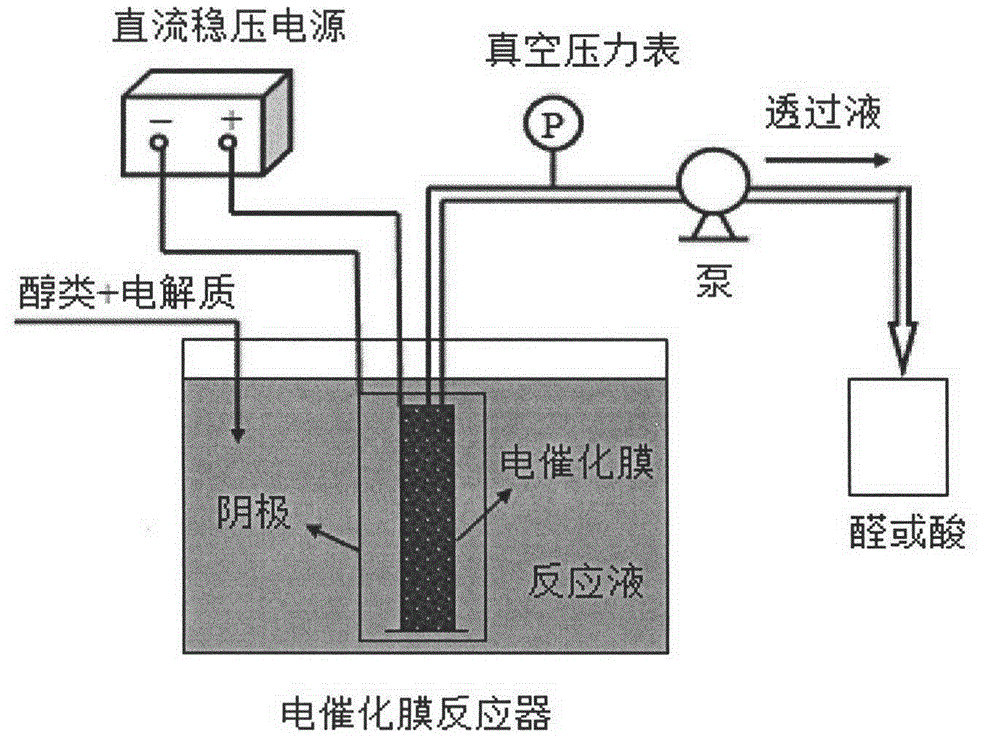

An electrocatalytic film and alcohol oxidation technology, which is applied in the electrolysis process, electrolysis components, electrolysis organic production, etc., can solve the problems of low solar energy utilization rate and difficult separation and recovery of photocatalysts, so as to maintain continuous high efficiency, avoid side reactions, The effect of simple equipment and process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] In this example, acetic acid is prepared from ethanol: a 0.05 mol / L ethanol aqueous solution is prepared and placed in a membrane reactor, and 7 g / L NaOH is added as an electrolyte. Under normal temperature and pressure, the working voltage is 1.5V and the current density is 0.9mA / cm 2 Under the conditions, the electrocatalytic membrane is used to catalyze the oxidation of ethanol to synthesize acetic acid. Gas chromatography-mass spectrometry was used to qualitatively and quantitatively detect the permeate of the reactor to obtain the conversion rate and yield of the reactant. In this experiment, the conversion rate of ethanol was 96.2%, and the yield of acetic acid was 88.7%.

Embodiment 2

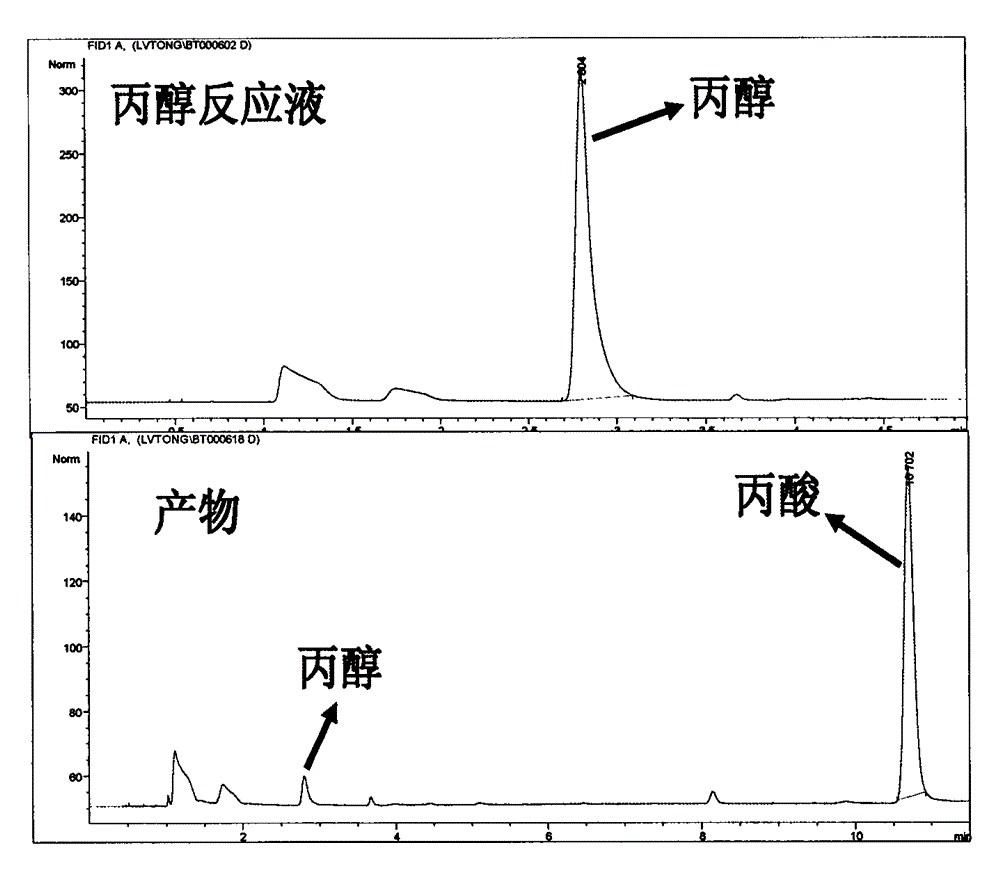

[0022] This example prepares propionic acid from propanol: prepare 0.03mol / L propanol aqueous solution and place it in a membrane reactor, add 5g / L NaHCO 3 as an electrolyte. Under normal temperature and pressure, the working voltage is 2.3V and the current density is 0.95mA / cm 2 Under these conditions, an electrocatalytic membrane was used to catalyze the oxidation of propanol to propionic acid. Gas chromatography-mass spectrometry was used to qualitatively and quantitatively detect the permeate of the reactor to obtain the conversion rate and yield of the reactant. The conversion rate of propanol in this experiment reaches 92.95%, and the productive rate of propionic acid reaches 79.83% (as figure 2 ).

Embodiment 3

[0024] This embodiment prepares butyric acid from butanol: prepare 0.1mol / L butanol aqueous solution and place it in the reactor, add 10g / LNa 2 CO 3 as an electrolyte. Under normal temperature and pressure, the working voltage is 3.5V and the current density is 10.0mA / cm 2 Under these conditions, the electrocatalytic membrane was used to catalyze the oxidation of butanol to synthesize butyric acid. Gas chromatography-mass spectrometry was used to qualitatively and quantitatively detect the permeate of the reactor to obtain the conversion rate and yield of the reactant. In this experiment, the conversion rate of butanol reached 98.84%, and the yield of butyric acid was 21.7%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com