Low-cost production method for container steel casting blanks

A container, low-cost technology, applied in the direction of improving process efficiency, manufacturing converters, etc., can solve the problems of low utilization rate of molten iron phosphorus, low surface crack rate of cast slabs, low cost, etc., to improve the utilization rate of molten iron phosphorus, The effect of improving the yield of molten steel and reducing the production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

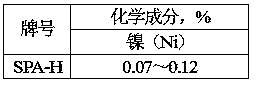

[0103] Example 1: 120-ton system: 106.07 tons of molten iron, 15.61 tons of scrap steel, basicity control at the end of the converter: 1.64; add 18.4 kg of light-fired steel per ton and 8.2 kg of lime per ton of steel, and the oxygen supply intensity is 2.1 to 3.1 Nm 3 / min·t, blowing to oxygen consumption 9.8Nm 3 End the oxygen supply at / t and then blow the gun again to the end point; tap carbon (C) at the end point: 0.05%, tap phosphorus (P): 0.069%, tap temperature: 1652°C, for the cooling water of the continuous casting mold The flow rate is controlled, the flow rate of cooling water is controlled at 7.9m / s, the specific water volume of secondary cooling is 1.03L / kg, the temperature of the tundish is controlled at 1533-1539°C; the section of the casting machine is 1010mm, and the casting speed is controlled at 1.45m / min to obtain steel The chemical composition of the slab is:

[0104] .

Embodiment 2

[0105] Example 2: 120-ton system: 109.54 tons of molten iron, 10.23 tons of scrap steel, basicity control at the end of the converter: 2.31; add 21.6 kg of light-fired steel per ton and 9.8 kg of lime per ton of steel, and the oxygen supply intensity is 2.2 to 3.4 Nm 3 / min·t, blowing to oxygen consumption 7.1Nm 3End the oxygen supply at / t and blow again to the end point; tap carbon (C) at the end point: 0.07%, tap phosphorus (P): 0.081%, tap temperature: 1641°C, for continuous casting crystallizer cooling water The flow rate is controlled, the flow rate of cooling water is controlled at 8.3m / s, the specific water volume of secondary cooling is 0.72L / kg, the temperature of the tundish is controlled at 1529-1536°C; the section of the casting machine is 1400mm, and the casting speed is controlled at 1.12m / min to obtain steel The chemical composition of the slab is:

[0106] .

Embodiment 3

[0107] Example 3: 120-ton system: 107.54 tons of molten iron, 14.23 tons of scrap steel, basicity control at the end of the converter: 1.89; add 18.8 kg of light-fired steel per ton and 8.4 kg of lime per ton of steel, and the oxygen supply intensity is 2.1 to 3.3 Nm 3 / min·t, one oxygen supply blowing to the end point; the end point tapping carbon (C): 0.06%, tapping phosphorus (P): 0.072%, tapping temperature: 1649 ° C, the cooling water flow rate of the continuous casting crystallizer is adjusted Control, control the flow rate of cooling water to 8.8m / s, the specific water volume of secondary cooling to 0.74L / kg, the temperature of the tundish to be controlled at 1534-1542°C; the cross-section of the casting machine: 1350mm, and the casting speed to be controlled at 1.12m / min to obtain the cast slab The chemical composition is:

[0108] .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com