PET composite material and preparation method thereof

A technology of composite materials and compounds, which is applied in the field of low-temperature-resistant halogen-free flame-retardant PET composite materials and its preparation, can solve the problems of low-temperature resistance and flame-retardant performance of PET materials, and achieve the effects of low cost, simple process, and elimination of influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The embodiment of the present invention further provides the above PET composite material preparation method, comprising the following steps:

[0037] Step S01, providing raw materials:

[0038] Weigh the thermoplastic polyester elastomer, PET, halogen-free flame retardant, compatibilizer, coupling agent and dispersant according to the formula;

[0039] Step S02, preparing the first mixture:

[0040] mixing the halogen-free flame retardant and coupling agent in a high mixer for 10 to 20 minutes to obtain the first mixture;

[0041] Step S03, preparing the second mixture:

[0042] mixing the first mixture, PET, dispersant, and dried thermoplastic polyester elastomer and compatibilizer to obtain a second mixture;

[0043] Step S04, extrusion process:

[0044] The second mixture is melt-extruded to obtain a PET composite material.

[0045] Specifically, in step S01, the thermoplastic polyester elastomer, PET, halogen-free flame retardant, compatibilizer, coupling agen...

Embodiment 1

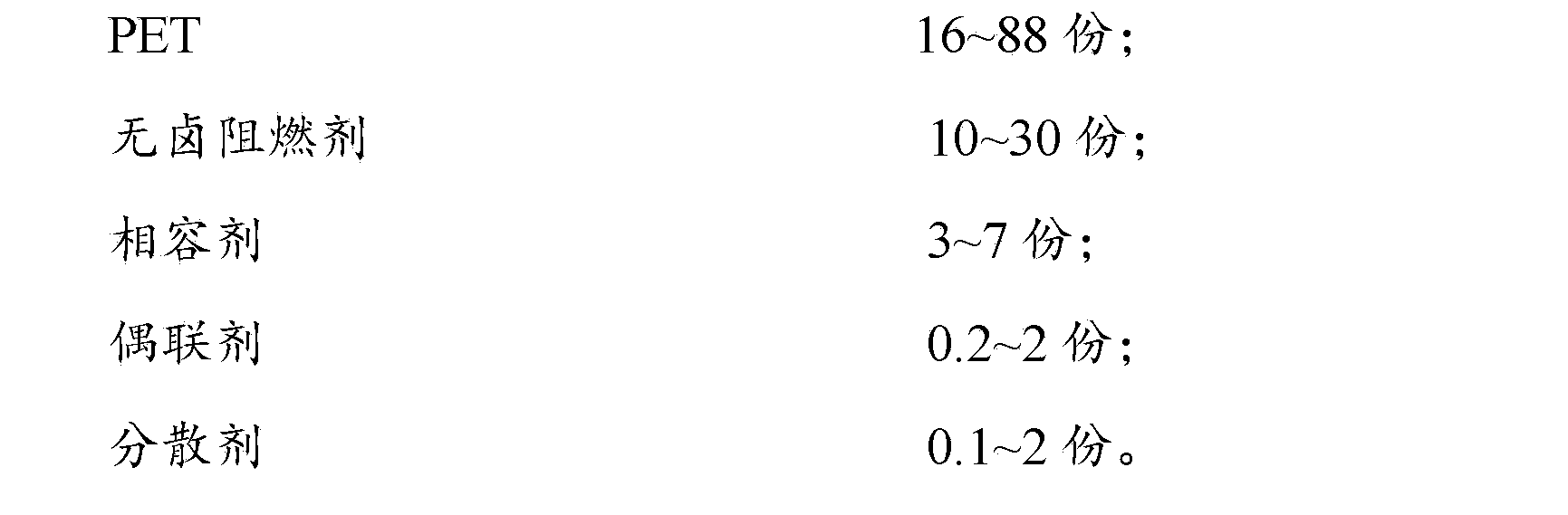

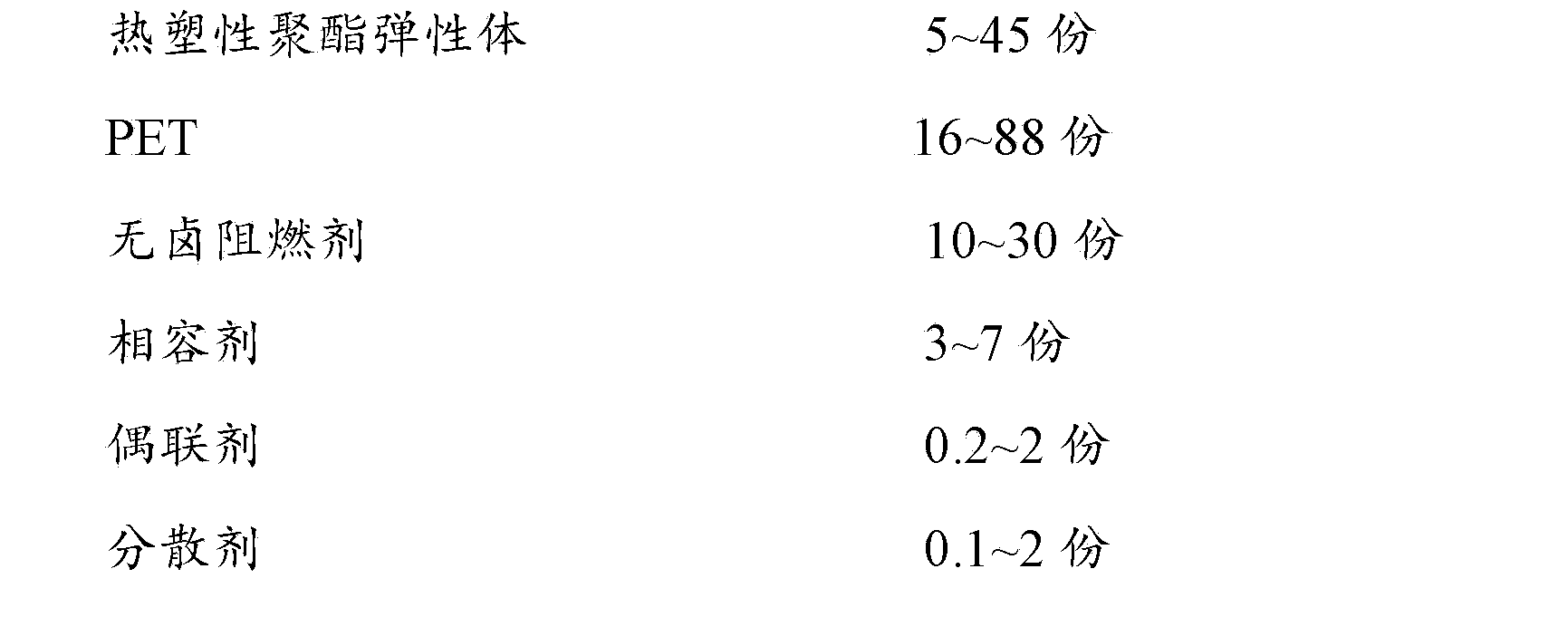

[0052] Embodiment PET composite material of the present invention, comprises the component of following parts by weight:

[0053] 5 parts of TPEE 7246; 82 parts of PET 1100; 3 parts of 790; 0.1 part of KH560; 0.1 part of ADR-4370; 9 parts of OP1240; 1 part of MR01;

Embodiment PE

[0054] The preparation method of the PET composite material of the embodiment of the present invention comprises the following steps:

[0055] a: Weigh the components with the above contents, first dry the thermoplastic polyester elastomer and compatibilizer in a vacuum oven at 45°C for 3-4 hours;

[0056] b: uniformly mixing the halogen-free flame retardant and the coupling agent in a high-speed mixer to obtain the first mixture;

[0057] c: Add the PET resin, dispersant, thermoplastic polyester elastomer and compatibilizer dried in step a to the first mixture, and continue mixing until uniform to obtain a second mixture;

[0058] d: Put the second mixture mixed in step c into the hopper of the twin-screw extruder, melt and extrude, and granulate; The temperature in the zone is 190°C, the temperature in the fourth zone is 200°C, the head is 220°C, the speed of the main engine is 450 rpm, and the pressure is 18MPa.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com