Water emulsion type polyvinyl chloride resin terminator and preparation method thereof

A technology of polyvinyl chloride resin and terminator, which is applied in the field of water-emulsion polyvinyl chloride resin terminator and its preparation, can solve the problems of single general efficiency, no thermal stabilization effect, and single function, and achieve simple and good production process Termination effect, effect of improving processability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

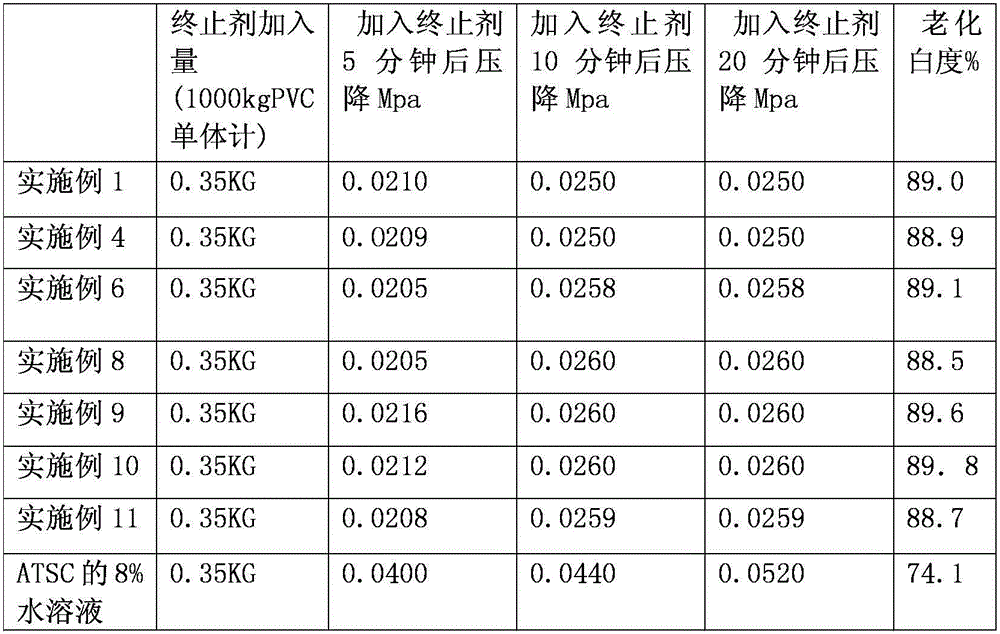

Examples

Embodiment 1

[0039] The preparation method of aqueous emulsion type polyvinyl chloride resin terminator comprises the following steps:

[0040] 1) Weigh 35g of liquid fatty acid zinc, 35g of diphenyl-isooctyl phosphite, 40g of 2,2-bis(4-hydroxyphenyl)propane, and 0.1g of benzene salicylate according to the weight of the above raw materials. ester, 4g of hydroquinone, 42g of sorbitan trioleate, 54g of polyoxyethylene sorbitan monolaurate, 8g of polyvinyl alcohol GH-20 and 320g of deionized water;

[0041] 2) Put the liquid fatty acid zinc, diphenyl-isooctyl phosphite and 2,2-bis(4-hydroxyphenyl)propane obtained in step 1) into a 1000mL flask, stir and dissolve at 125°C, and keep warm After 3 hours, it was lowered to normal temperature to obtain a mixed solution;

[0042] 3) Add phenyl salicylate and hydroquinone to the mixed solution obtained in step 2), and stir evenly to obtain a mixed terminator solution;

[0043] 4) Add sorbitan trioleate and polyoxyethylene sorbitan monolaurate to th...

Embodiment 2

[0047] The preparation method of aqueous emulsion type polyvinyl chloride resin terminator comprises the following steps:

[0048] 1) Weigh 27g of liquid fatty acid zinc, 48g of triphenyl phosphite, 65g of epoxy linseed oil, 9g of bisphenol A phosphite, 9g of 2,2-bis(4 -Hydroxyphenyl)propane, 0.2g of 2.5-bis-(5-tert-butyl-2-benzoxazolyl)thiophene, 0.1g of phenyl salicylate, 18g of 2-phenylpropene, 5g of sorbic acid Alcohol monolaurate, 8 g of sorbitan trioleate, 1 g of sodium dodecylbenzenesulfonate and 100 g of deionized water;

[0049] 2) Put the liquid fatty acid zinc, triphenyl phosphite, epoxy linseed oil, bisphenol A phosphite and 2,2-bis(4-hydroxyphenyl)propane obtained in step 1) at 160°C Stir to dissolve, keep warm for 2 hours and drop to normal temperature to obtain a mixed solution;

[0050]3) Add 2.5-bis-(5-tert-butyl-2-benzoxazolyl)thiophene, phenyl salicylate and 2-phenylpropene to the mixture obtained in step 2), and stir well to obtain the mixture termination...

Embodiment 3

[0055] The preparation method of aqueous emulsion type polyvinyl chloride resin terminator comprises the following steps:

[0056] 1) Weigh 21g of calcium stearate, 39g of diphenylisodecyl phosphite, 40g of epoxidized soybean oil, 12g of bisphenol A phosphite, 18g of 2, 2-bis(4-hydroxyphenyl)propane, 0.2g of 2,4-dihydroxybenzophenone, 5g of p-tert-butylcatechol, 5g of 2-phenylpropylene, 30g of polyoxyethylene sorbitan Monooleate, 10g of emulsifier OS-15, 4g of polyvinyl alcohol GH-22 and 200g of deionized water, standby;

[0057] 2) The calcium stearate obtained in step 1), diphenylisodecyl phosphite, epoxidized soybean oil, bisphenol A phosphite and 2,2-bis(4-hydroxyphenyl)propane Stir and dissolve at 90°C, keep warm for 5 hours and then lower to room temperature to obtain a mixed solution;

[0058] 3) Add 2,4-dihydroxybenzophenone, p-tert-butylcatechol and 2-phenylpropylene to the mixed solution obtained in step 2), and stir evenly to obtain a mixed terminator solution;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com