Synthesis method of 1-benzylpyridinium-3-carboxylate

A technology of benzyl nicotinic acid salt and synthesis method, applied in the direction of organic chemistry, etc., can solve the problems of long reaction time, poor water solubility of the product, deep red color, etc., and achieve short reaction time, good uniform plating and deep plating The effect of ability and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

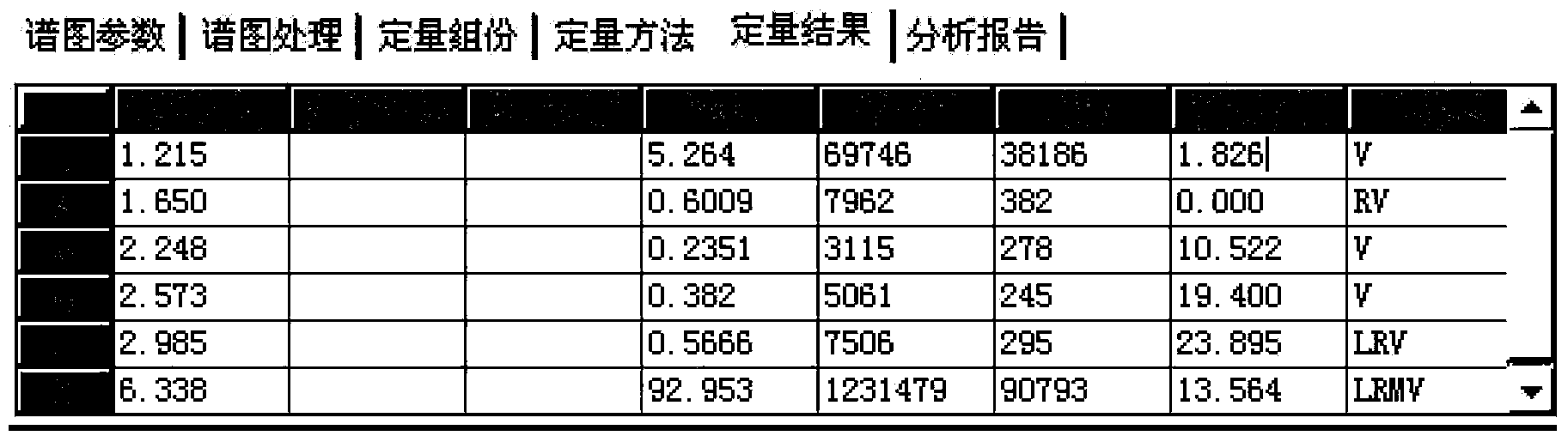

Image

Examples

Embodiment 1

[0021] Add 2.2kg of deionized water to a 5L four-neck flask, add 0.4kg of sodium hydroxide to dissolve, then slowly add 1.23kg of nicotinic acid at 40°C, continue to stir and dissolve, and gradually add 5gK 2 CO 3 , 5g trioctylmethyl ammonium chloride, 10g boric acid, the solution is neutral, and the temperature is raised to 80°C, and 1.26kg of benzyl chloride is started to be added dropwise, at a temperature of 80-90°C. After 1 hour, the reaction was completed, and benzyl nicotinic acid salt was obtained, and the appearance was a light yellow transparent liquid.

Embodiment 2

[0024] Add 480g of deionized water to a 1L four-neck flask, add 80g of sodium hydroxide to dissolve, then slowly dissolve 240g of nicotinic acid at 50°C, continue to stir and dissolve, and gradually add 1g of NaOH 2 CO 3 , 0.5g tetrabutylammonium bromide, 5g sodium bicarbonate, the solution is weakly alkaline, heat up to 70°C, start to add 200g of benzyl chloride dropwise, the dropwise addition temperature is 70-80°C, after the dropwise addition is completed, keep the temperature at this temperature After 2 hours, the reaction was completed to obtain benzyl nicotinic acid salt, and the appearance was a yellow transparent liquid. The concentration is 90.17%.

Embodiment 3

[0026] Add 520g of deionized water to a 1L four-neck flask, add 80g of sodium hydroxide to dissolve, then slowly dissolve 246g of nicotinic acid at 60°C, continue to stir and dissolve, and gradually add 3g of K 2 CO 3 , 1g of bromogeramine, 6g of sodium acetate, the solution is weakly alkaline, the temperature is raised to 80°C, and 240g of benzyl chloride is started to be added dropwise at a temperature of 80-95°C. After the addition is completed, the temperature is kept at this temperature for 1 hour. Benzyl nicotinic acid salt, the appearance is a yellow transparent liquid. The concentration is 91.26%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com