Method for quickly improving enrichment rate and degree of ammonia-oxidizing bacteria (AOB) in sequencing batch reactor (SBR)

A sequencing batch reactor and ammonia oxidizing bacteria technology, applied in chemical instruments and methods, water/sludge/sewage treatment, biological water/sewage treatment, etc., can solve the problem of long enrichment time of ammonia oxidizing bacteria, Low enrichment degree and other problems, to achieve the effect of short enrichment time and high enrichment degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

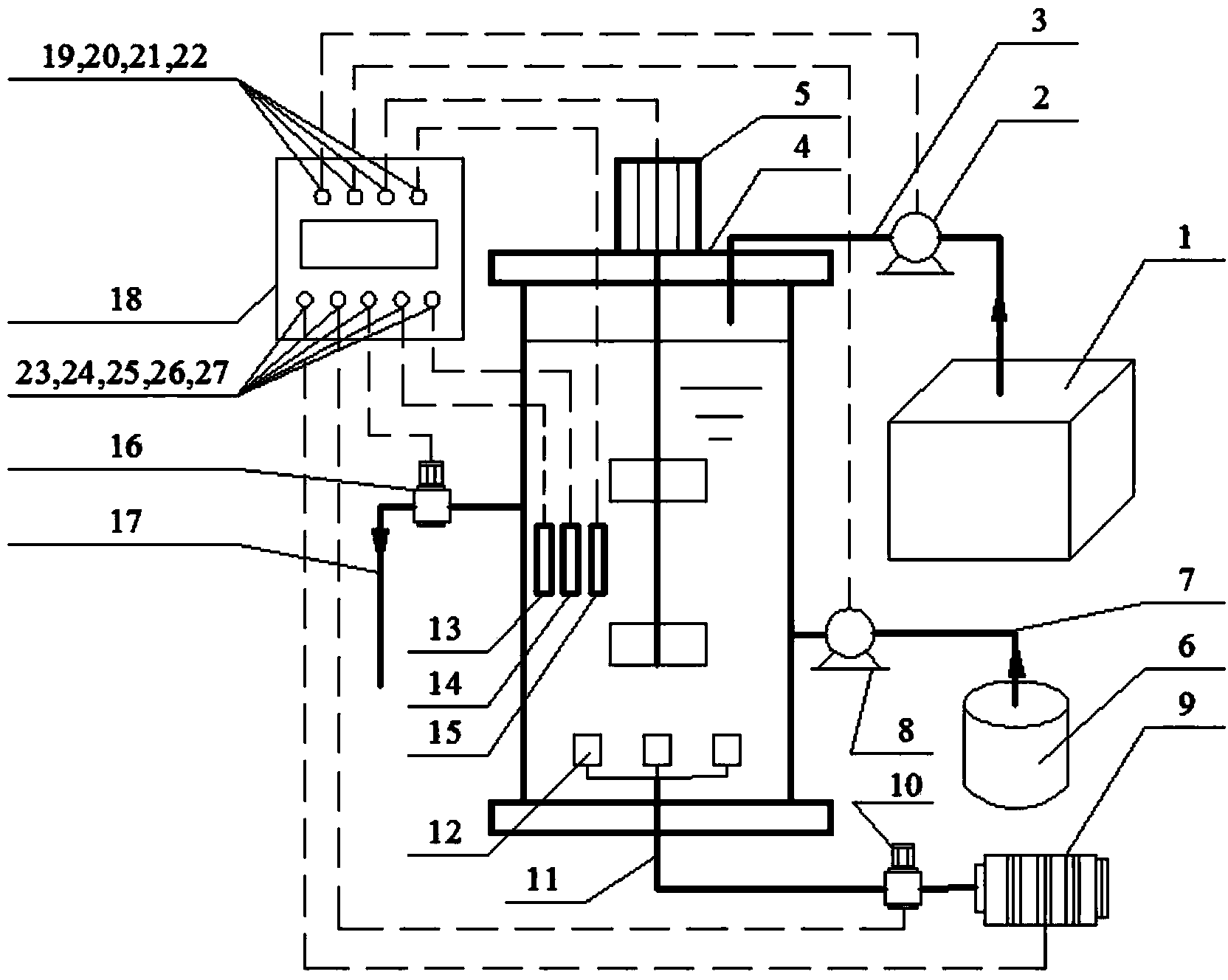

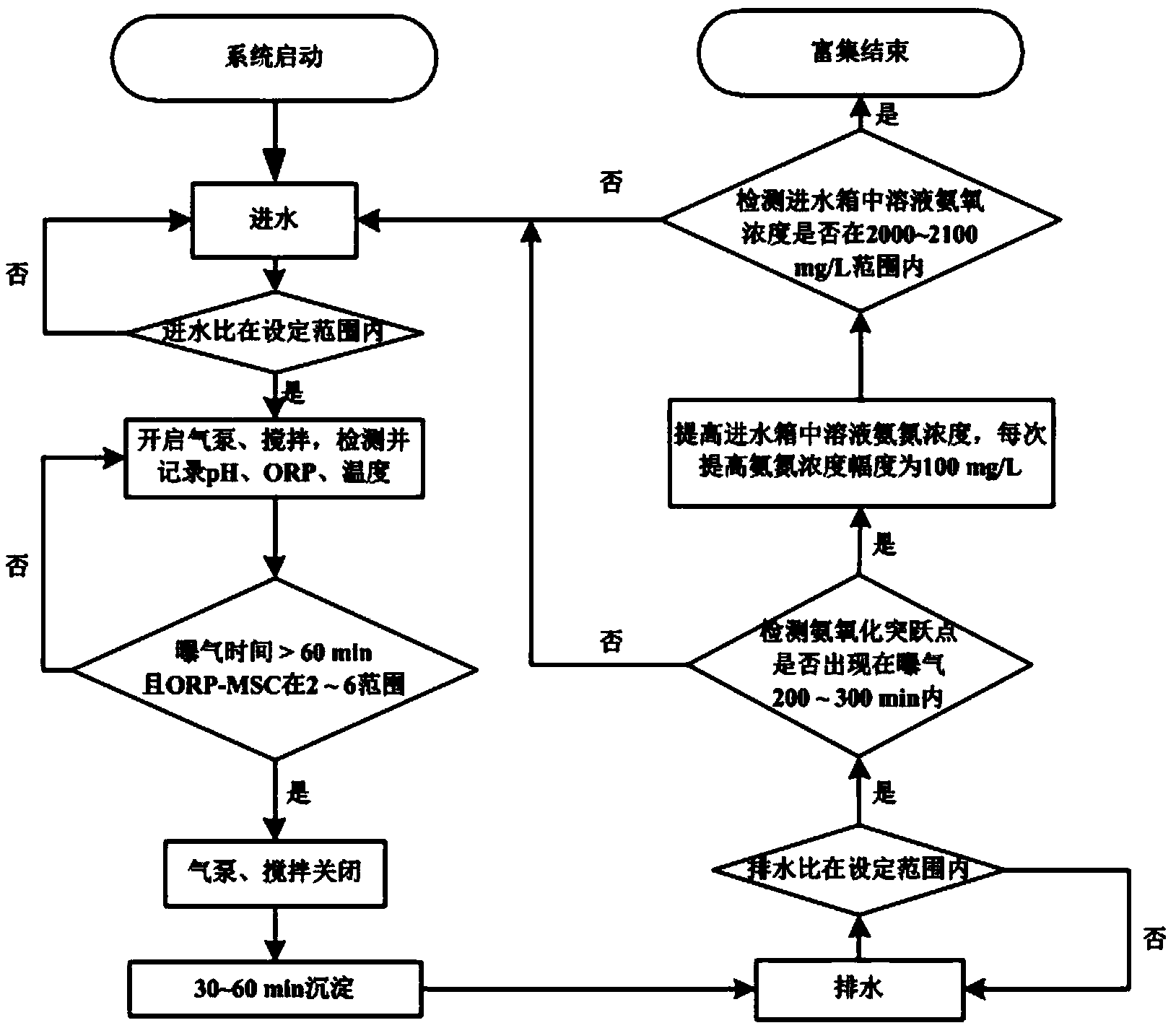

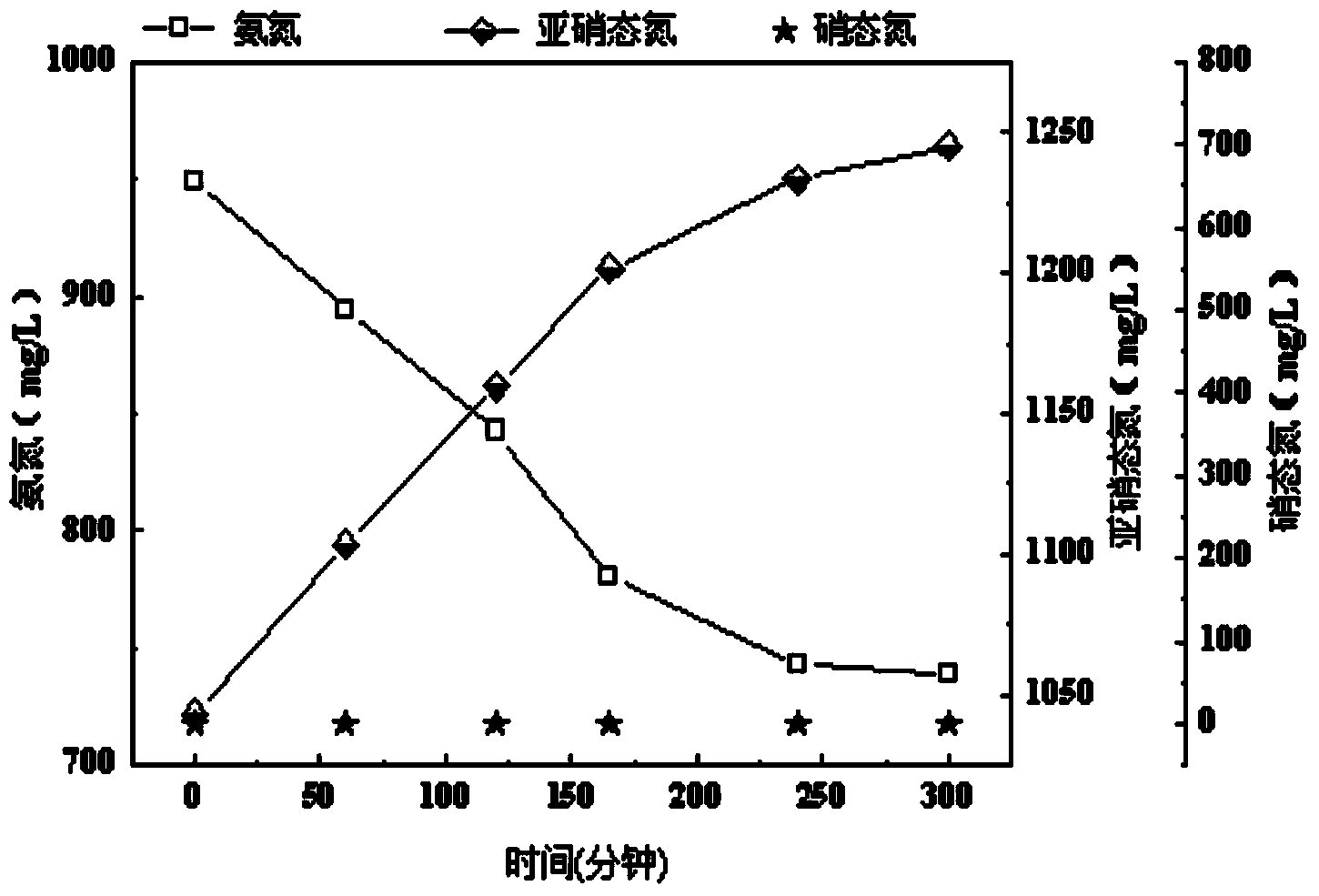

[0033]The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments: the influent adopts artificially configured sewage (pH=7.2-7.9, COD=10-20mg / L, NH 4 + -N=100-2000mg / L), the main components of artificially prepared sewage are ammonium bicarbonate, potassium dihydrogen phosphate, dipotassium hydrogen phosphate and trace element solution. The test device uses a small test SBR with an effective volume of 8L as the ammonia oxidizing bacteria enrichment reactor, and the water treatment volume per cycle is 2L. After the water intake is completed, the NH 4 + - The concentration of N is 25-900mg / L, the operating temperature of the system is 25°C, and the operation steps of each cycle are as follows:

[0034] 1) The water inlet ratio of the ammonia oxidizing bacteria enrichment reactor is 25%. Start the water inlet pump to add ammonia nitrogen-containing sewage from the water inlet tank to the ammonia oxidizing bacteri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com