Flash evaporation tank

A flash tank and tank technology, applied in the field of chemical equipment, can solve the problems of product loss, affecting gas quality, incomplete vapor-liquid separation, etc., and achieve the effect of less waste gas pollution, good defoaming effect, and saving raw materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

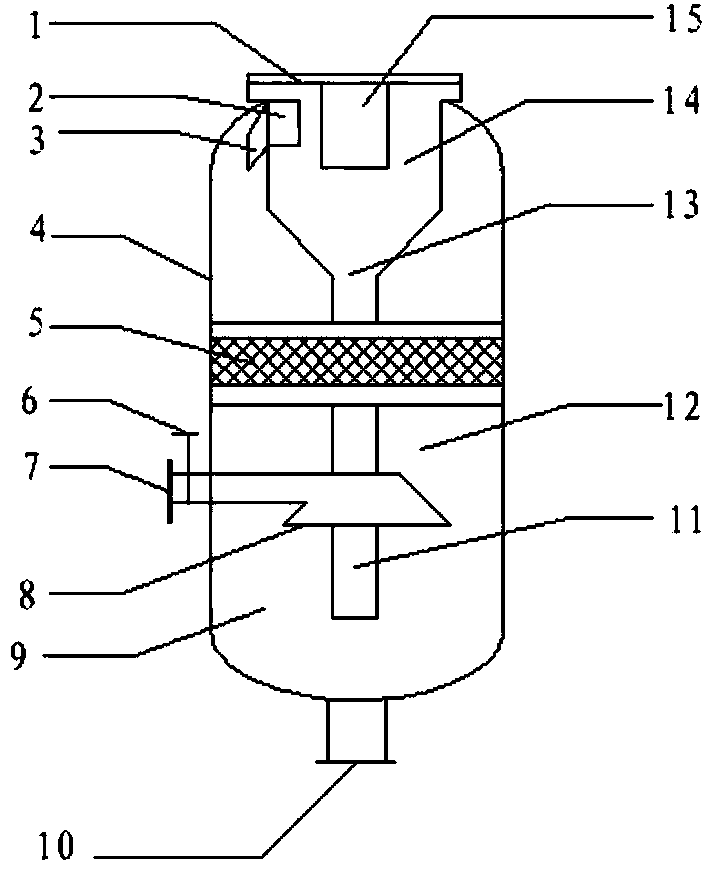

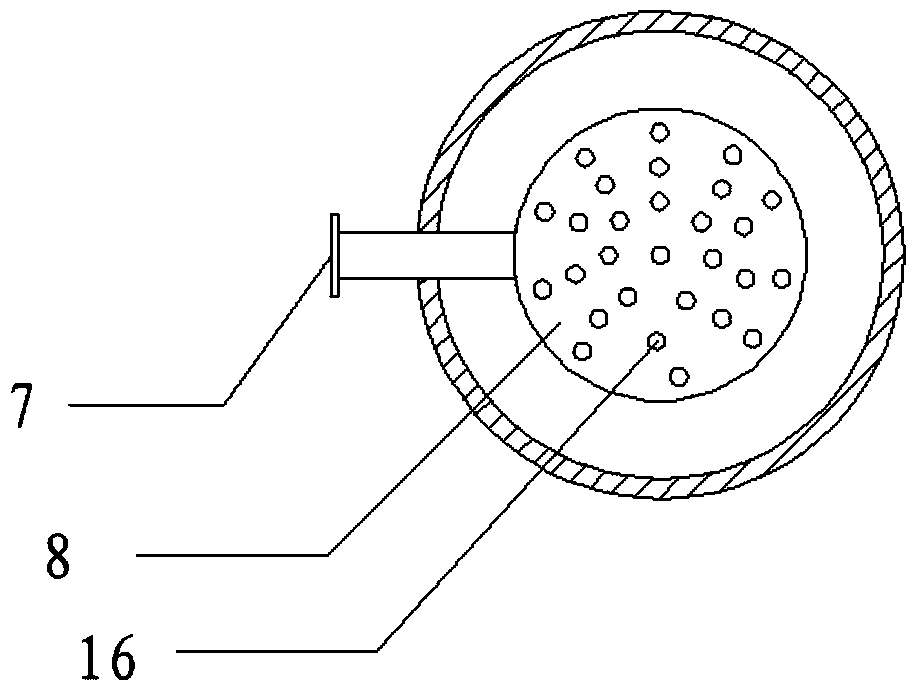

[0017] The present invention will be further described below in conjunction with the accompanying drawings. figure 1 with figure 2 They are the structural schematic diagram of the flash tank in the present invention and the sectional view of the feed pipe respectively. Such as figure 1 As shown, the flash tank includes a tank body 4 , a feed pipe 7 , a demister 5 , a separation device 13 , a gas outlet pipe 15 , and a discharge pipe 10 . The tank body 4 is made of stainless steel; the feed pipe 7 is located below the tank body 4 and extends into the inner cavity of the tank body 4. The feed pipe 7 is provided with a valve 6 and a nozzle 8, and the nozzle 8 is densely covered with nozzle holes 16. 8 Divide the inner cavity of the tank body 4 into a spray chamber 9 and an expansion chamber 12; the demister 5 is located above the feed pipe 7 and is composed of wire mesh packing; the separation device 13 is located above the tank body 4, and the separation device 13 can be Var...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com