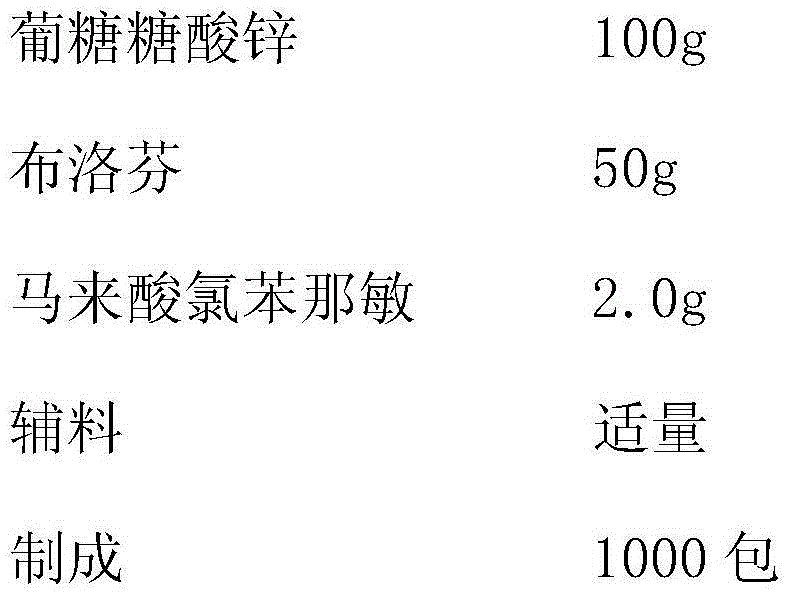

Preparation method of compound zinc gluconate and ibuprofen granules

A granule and zinc cloth technology, which is applied in the directions of non-active ingredients medical preparations, medical preparations containing active ingredients, pharmaceutical formulas, etc., can solve the problems of acute toxicity hazards, low work efficiency, environmental pollution, etc. Acute toxicity hazards and serious environmental pollution, improving work efficiency and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

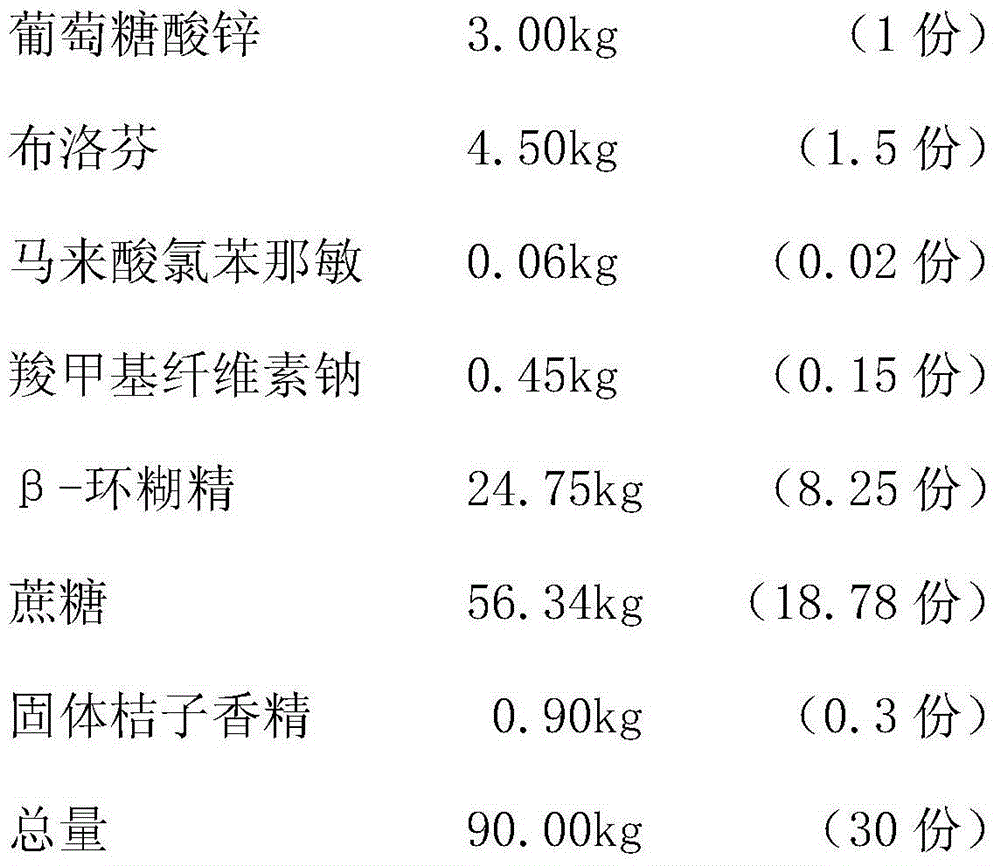

[0041] (1) Add 2 times the volume of 95% (volume concentration) ethanol to 4.50kg of ibuprofen, and heat it in a water bath below 70°C until the ibuprofen is completely dissolved. During this process, no crumbs of ibuprofen float on the surface of the solution No oil drop ibuprofen coverage;

[0042] (2) Add 1 times the volume of purified water to 24.75kg of β-cyclodextrin to disperse, and stir well until it becomes a slurry;

[0043] (3) Use a homogenizer or a colloid mill to stir the β-cyclodextrin slurry, while stirring, slowly add the ibuprofen alcohol solution to the β-cyclodextrin slurry at a uniform speed, and continue stirring for 1 hour after adding to obtain inclusion material suspension, put it aside;

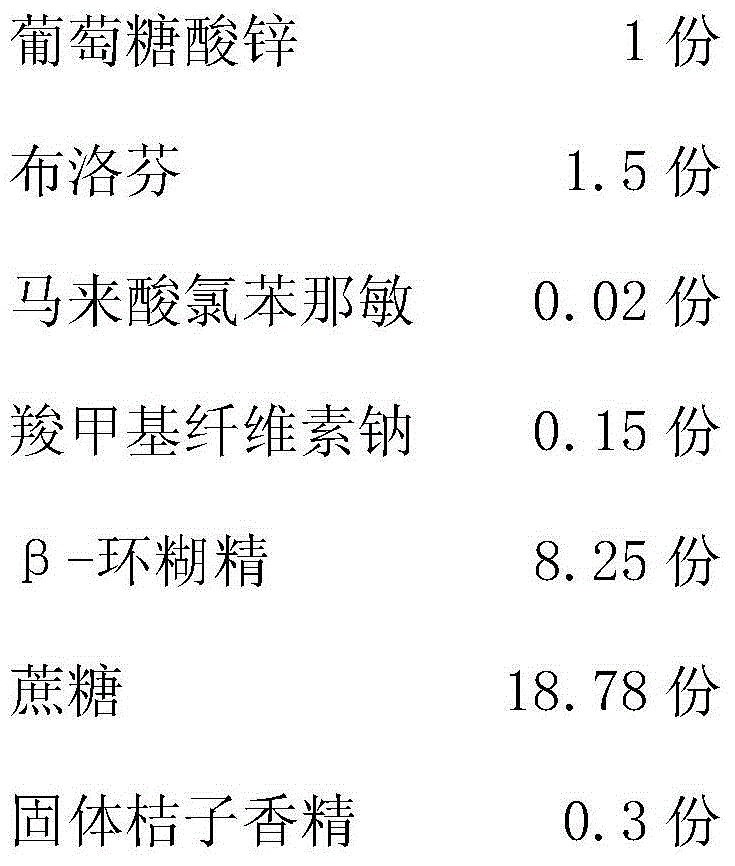

[0044] (4) Grind sucrose, pass through 80-mesh sieve, and set aside; mix 3.00kg of zinc gluconate, 0.06kg of chlorpheniramine maleate, 0.45kg of sodium carboxymethyl cellulose, and 56.34kg of sucrose evenly , transferred to the pot of the spray granulator, put the ...

Embodiment 2

[0049] (1) Add 2.5 times the volume of 95% (volume concentration) ethanol to 4.50kg ibuprofen, and heat it in a water bath below 70°C until the ibuprofen is completely dissolved. During this process, there is no floating ibuprofen debris on the surface of the solution No oil drop ibuprofen coverage;

[0050] (2) Add 1.5 times the volume of purified water to 24.75kg of β-cyclodextrin to disperse, and stir well until it becomes a slurry;

[0051] (3) Use a homogenizer or a colloid mill to stir the β-cyclodextrin slurry, and slowly add the ibuprofen alcohol solution to the β-cyclodextrin slurry at a uniform speed while stirring, and continue stirring for 1 hour after adding to obtain inclusion material suspension, put it aside;

[0052] (4) Grind sucrose, pass through 80-mesh sieve, and set aside; mix 3.00kg of zinc gluconate, 0.06kg of chlorpheniramine maleate, 0.45kg of sodium carboxymethylcellulose, and 56.34kg of sucrose evenly , transferred to the pot of the spray granulat...

Embodiment 3

[0057] (1) Add 3 times the volume of 95% (volume concentration) ethanol to 4.50kg ibuprofen, and heat it in a water bath below 70°C until the ibuprofen is completely dissolved. During this process, there is no floating ibuprofen debris on the surface of the solution No oil drop ibuprofen coverage;

[0058] (2) Add 2.5 times the volume of purified water to 24.75kg of β-cyclodextrin to disperse, and stir until it becomes a slurry;

[0059] (3) Use a homogenizer or a colloid mill to stir the β-cyclodextrin slurry, while stirring, slowly add the ibuprofen alcohol solution to the β-cyclodextrin slurry at a uniform speed, and continue stirring for 1 hour after adding to obtain inclusion material suspension, put it aside;

[0060] (4) Grind sucrose, pass through 80-mesh sieve, and set aside; mix 3.00kg of zinc gluconate, 0.06kg of chlorpheniramine maleate, 0.45kg of sodium carboxymethyl cellulose, and 56.34kg of sucrose evenly , transferred to the pot of the spray granulator, put the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com