Comprehensive factory-like circulation production method of pleurotus eryngii and common edible mushrooms

A production method and integrated factory technology, applied in the direction of botany equipment and methods, applications, products, etc., can solve the problems of low-cost perennial production, low production efficiency, short fruiting period, etc., and reduce the infection rate of bacterial packs , high production efficiency and short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

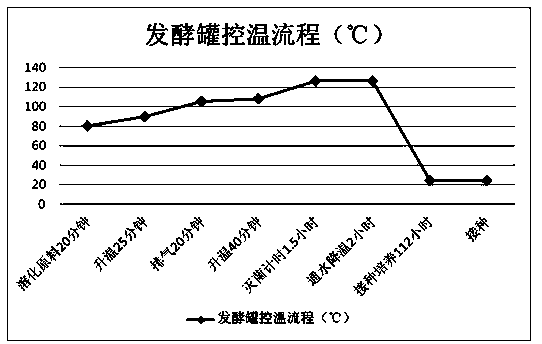

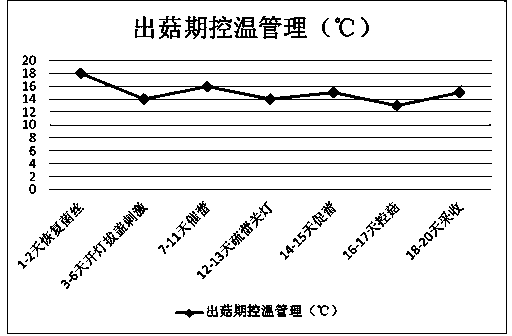

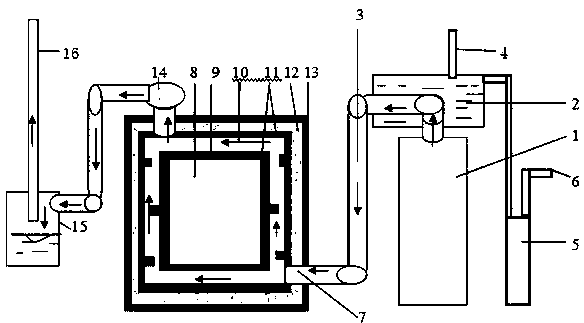

[0039] Embodiment 1: see Figure 1 to Figure 5 .

[0040] In the production method of Pleurotus eryngii, almost all the materials used are agricultural by-products and straws and other leftovers, such as cottonseed hulls, corn cobs, cotton stalk powder, sawdust, bran, rice bran, soybean meal, cornmeal, etc. We are located in the North China Plain, where crops are abundantly cultivated, materials are easy to obtain, low in price, and inexhaustible. While achieving high benefits in the production of edible fungi, we also solve the problem of difficult disposal of crop stalks, which can be said to serve multiple purposes.

[0041] 1. Ingredients and mixing:

[0042] Cotton stalks should be crushed to 1-3mm thick and 3-8mm long debris, and soaked one day in advance; corn cobs should be crushed to 3-5mm particles, soaked and pre-wetted with cotton seed hulls for 2-6 hours in advance; rice bran, bran and other fine materials It should be added while mixing. The weighing of the in...

Embodiment 2

[0074] Pleurotus eryngii cultivation substrate preparation: ingredients according to the following mass ratio, 10 parts of cottonseed husk, 22 parts of corn cob, 12 parts of cotton stalk powder, 12 parts of sawdust, 10 parts of bran, 10 parts of rice bran, 4 parts of cornmeal, soybean meal 3 parts, plus 0.5 parts of quicklime and 0.5 parts of calcium carbonate, the moisture content is 62-63%, mixed and stirred by the mixing production line, and the pH value is adjusted to 7.5-8;

[0075] Production of liquid strains: first prepare the liquid mother species of the triangular flask: the formula of the triangular flask liquid medium is as follows: 7 parts of potatoes (boiled water), 1.5 parts of wheat bran, 0.5 parts of brown sugar, 0.4 parts of glucose, 0.09 parts of peptone, potassium dihydrogen phosphate 0.04 parts, magnesium sulfate 0.04 parts, vitamin B1 10 mg / liter, water 100 parts. Each test tube mother seed is connected with 2-3 bottles of triangular flask liquid mother s...

Embodiment 3

[0080] Pleurotus eryngii cultivation substrate preparation: ingredients according to the following mass ratio, 14 parts of cottonseed husk, 27 parts of corn cob, 18 parts of cotton stalk powder, 18 parts of sawdust, 14 parts of bran, 14 parts of rice bran, 5 parts of cornmeal, soybean meal 5 parts, plus 1.5 parts of quicklime and 1.5 parts of calcium carbonate, the moisture content is 62-63%, mixed and stirred by the mixing production line, and the pH value is adjusted to 7.5-8;

[0081] Production of liquid strains: first prepare the liquid mother seed of the triangular flask: the formula of the triangular flask liquid medium is as follows: 9 parts of potatoes (boiled water), 2.5 parts of wheat bran, 0.7 parts of brown sugar, 0.6 parts of glucose, 0.11 parts of peptone, potassium dihydrogen phosphate 0.06 parts, magnesium sulfate 0.06 parts, vitamin B1 10 mg / liter, water 100 parts. Each test tube mother seed is connected with 2-3 bottles of triangular flask liquid mother seed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com