Cellulose fiber and manufacturing process therefor, cellulose fiber aggregate and cellulose fiber composite material

一种纤维素纤维、纤维素的技术,应用在纤维素纤维领域,能够解决制造工序复杂、N-烃氧基化合物高价、制造费用高等问题,达到不易着色问题、开纤性优异、抑制着色的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0324] Hereinafter, although an Example and a comparative example demonstrate this invention more concretely, unless the summary of this invention is exceeded, this invention is not limited to the following Example.

[0325] In addition, the measurement methods of YI of the cellulose fiber aggregate obtained by this invention, the cellulose content of a cellulose fiber composite material, YI, haze, total light transmittance, and linear expansion coefficient are as follows.

[0326] 〔Cellulose content in cellulose fiber composite material〕

[0327] The cellulose content (% by weight) was determined from the weight of the cellulose fiber aggregates used for compounding and the weight of the obtained cellulose fiber composite material.

[0328] [YI of cellulose fiber aggregate, YI of cellulose fiber composite material]

[0329] YI was measured using a color computer manufactured by Suga Test Instruments. A large YI indicates strong coloring.

[0330] 〔Haze of cellulose fiber c...

Embodiment I-1

[0338]

[0339] As the cellulose fiber raw material, broadleaf bleached kraft pulp (hereinafter abbreviated as LBKP) was used. The amount of carboxyl groups in this LBKP was 0.06 mmol / g.

[0340] 200 g (solid content 20% by weight, water content 80% by weight, 40 g as absolute dry cellulose) of LBKP was suspended in 500 ml of 0.1M sulfuric acid and stirred. The suspension was filtered under reduced pressure using filter paper to obtain LBKP wetted with dilute sulfuric acid. LBKP is put into the detachable flask, to the oxygen containing ozone (gas flow rate 2L / min, ozone concentration 32g / m 3 , ozone generation amount 4g / Hr) carried out ventilation exposure for 5 hours.

[0341] Then, the LBKP was taken out from the separable flask, suspended and washed with ion-exchanged water repeatedly, and the pH of the washing water reached 4.5 or more as the end point of washing. Then. Filtration under reduced pressure was performed with filter paper to obtain cellulose fiber A (so...

Embodiment II-1

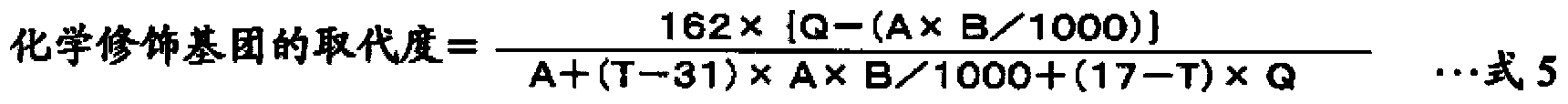

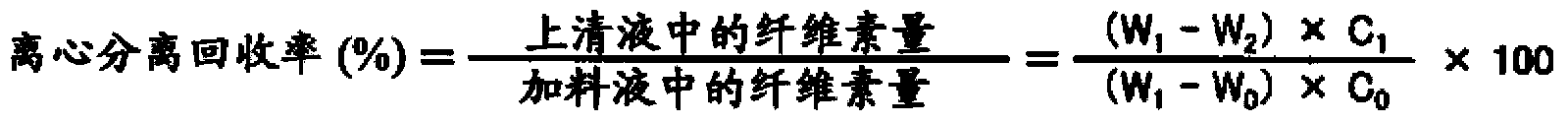

[0372] In Example I-1, the aqueous suspension of about 0.5% by weight of fiber-opened cellulose fibers after the aqueous suspension of cellulose fiber C was treated with a high-speed rotary homogenizer at 20,000 rpm for 1 hour was processed at 18,000 rpm ( 38900G) was centrifuged for 10 minutes to obtain a supernatant. The obtained supernatant contained fibrillated cellulose fibers, and the solid content (cellulose fibers) concentration of the supernatant was 0.0871% by weight. The centrifugation recovery rate of the fibrillated cellulose fibers at this time was calculated from the following formula and found to be 16.9%.

[0373] [mathematical formula 2]

[0374]

[0375] C 0 : Cellulose fiber concentration of the aqueous suspension of fibrillated cellulose fibers before centrifugation

[0376] C 1 : Cellulose fiber concentration of the supernatant

[0377] W 0 : Quality of centrifuge tube

[0378] W 1 : centrifuge tube + liquid quality

[0379] W 2 : centrifuge ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com