Hydraulic damper with actively-adjustable damping

A hydraulic shock absorber and damping technology, applied in the field of hydraulic shock absorbers, can solve the problems of high manufacturing cost, complex structure, unstable performance of shock absorbers, etc., and achieve the effects of reliable performance, low requirements and cost reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

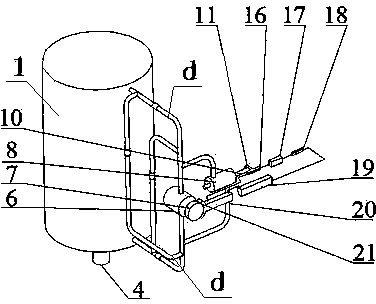

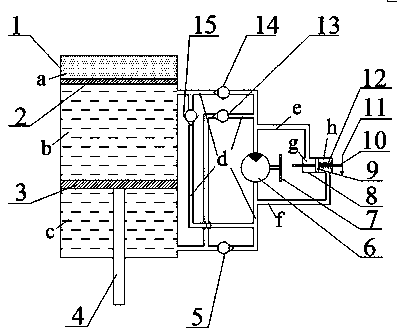

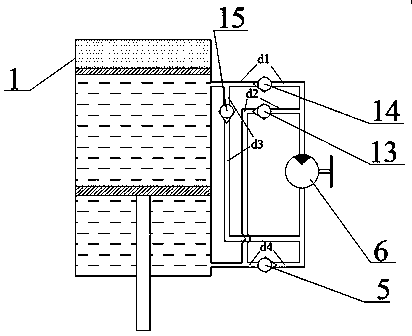

[0019] Such as figure 1 and figure 2 As shown, the shock absorber of the present invention includes a cylinder body 1 , a floating piston 2 , a piston 3 and a piston rod 4 . Both the floating piston 2 and the piston 3 are located in the cylinder body 1, and both are in sealing contact with the inner wall of the cylinder body 1, the floating piston 2 is above the piston 3, and the floating piston 2 and the piston 3 divide the cylinder body 1 into the upper compressed air chamber a, The upper oil chamber b in the middle and the lower oil chamber c in the lower part. The piston rod 4 is connected with the piston 3 and protrudes from the lower end of the cylinder body 1 . The compressed air chamber a can effectively reduce the high-frequency vibration generated when the wheel receives a sudden impact, and compensate the reduction of the oil storage volume of the cylinder 1 caused by the piston rod 4 entering the cylinder 1 . Outside the cylinder body 1, the oil between the upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com