Flexible veneer overlaid cement particle board

A particleboard and flexible technology, applied in the field of flexible veneer veneer cement particleboard, to achieve the effect of smooth and full board surface, improved application range and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

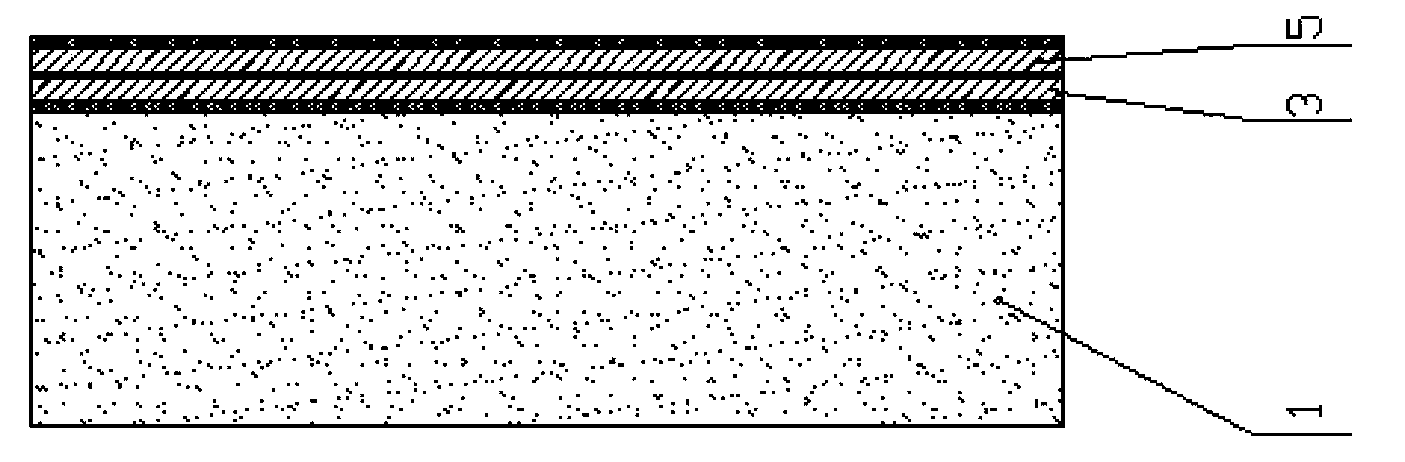

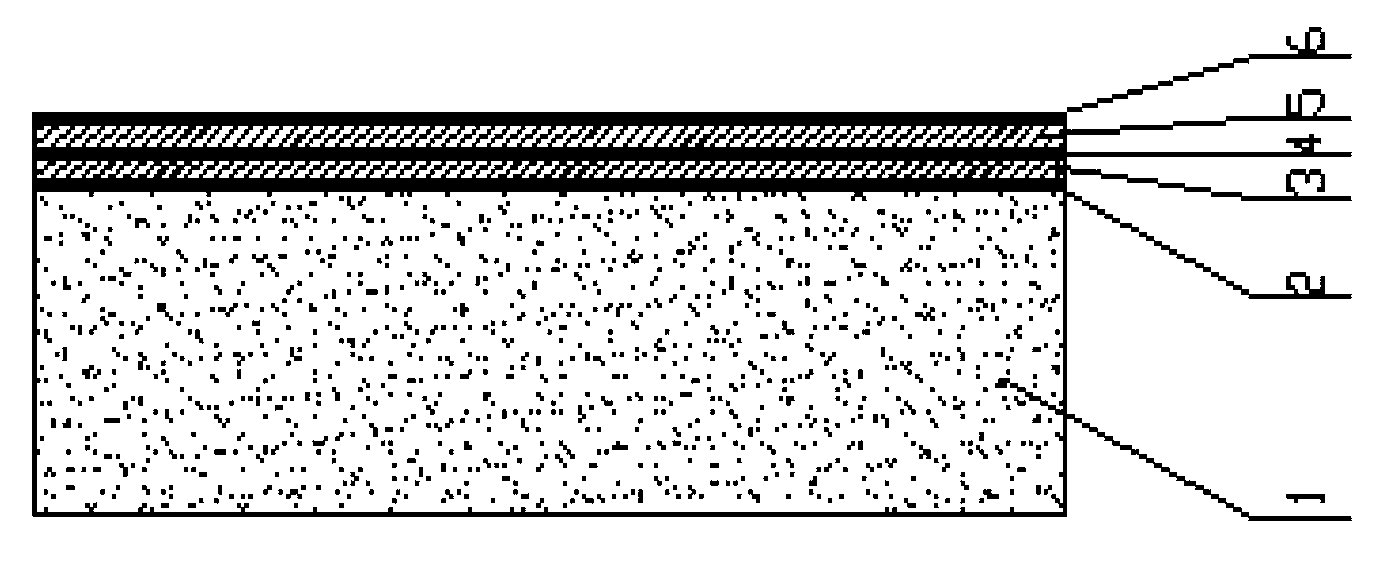

[0023] Specific implementation mode 1: the following combination figure 1 with figure 2 This embodiment will be specifically described. A flexible veneer veneer composite board, which comprises a base plate 1, an upper glue layer 2 between the base plate and an upper veneer balance layer 3, an upper veneer balance layer 3, an upper veneer balance layer 3 and an upper layer impregnated with melamine resin The upper melamine resin layer 4 between the flexible veneer layers 5 , the upper flexible veneer layer 5 impregnated with melamine resin and the upper surface adhesive layer 6 of the impregnated melamine resin flexible veneer. The upper veneer balance layer 3 is tiled on the surface of the base material, making the surface of the composite board described in this embodiment more beautiful. Fewer substrate defects are exposed. One side of the substrate 1 is pressed together with the upper veneer balance layer 3 and the upper flexible veneer 5 impregnated with melamine resi...

specific Embodiment approach 2

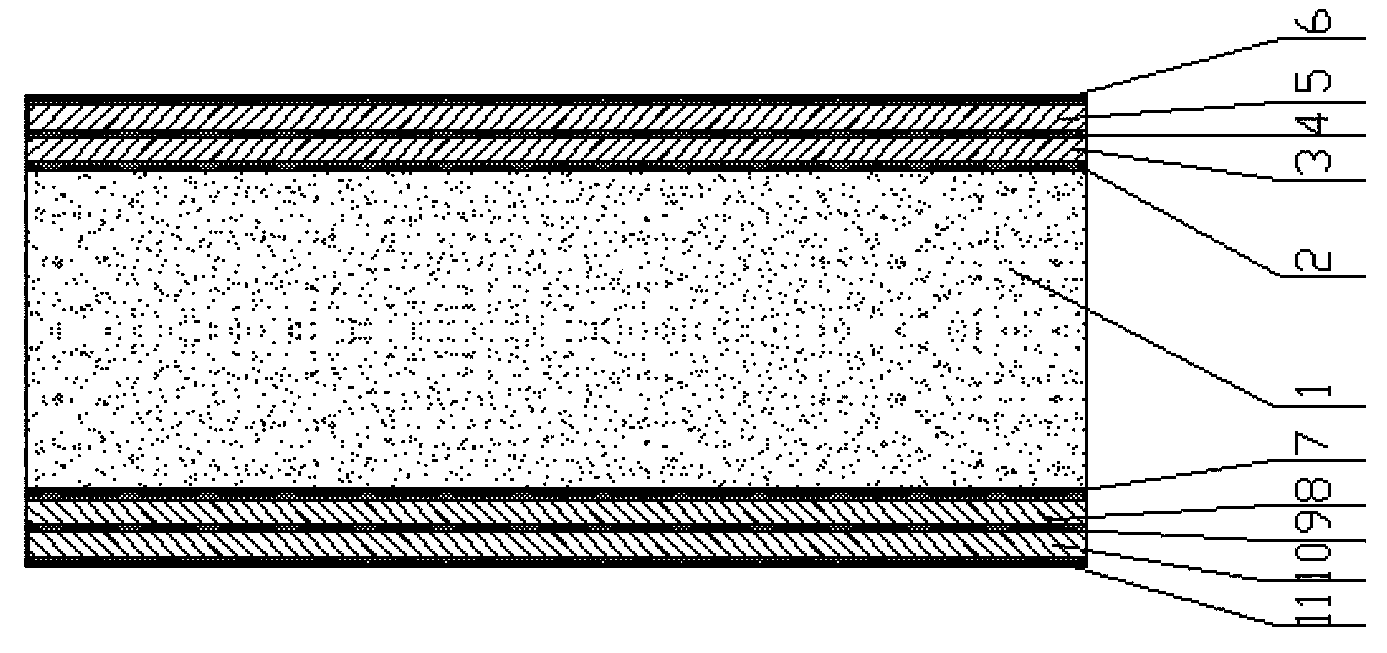

[0029] Specific implementation mode 2: combine below Figures 1 to 3 Describe this embodiment in detail: the difference between this embodiment and Embodiment 2 is that it also includes a lower veneer balance layer 8, a lower adhesive layer 7 between the lower veneer balance layer 8 and the substrate, and a lower impregnated melamine resin adhesive. The lower adhesive layer 9 between the flexible thin wood layer 10 and the lower veneer balance layer 8, the flexible thin wood layer 10 impregnated with melamine resin adhesive, and the adhesive layer 11 on the surface of the flexible thin wood layer 10 impregnated with melamine resin adhesive.

[0030] In this embodiment, both sides of the cement particle board composite board can be used as surface layers. The product described in this embodiment is more suitable for interior decoration, kitchens, greenhouses, air ducts, underground civil engineering, and various high and low-rise buildings. , not only can reduce the secondary ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com