Non-painting veneer composite board prepared under condition of low temperature and low pressure

A veneer composite board, low temperature and low pressure technology, applied to furniture parts, adhesive types, aldehyde/ketone condensation polymer adhesives, etc., can solve secondary pollution and other problems, achieve smooth and full board surface, and save wood resources and improve the effect of comprehensive utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

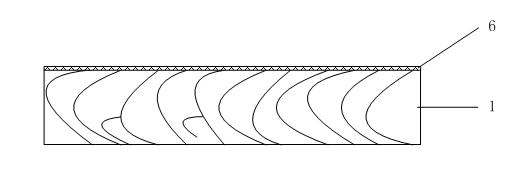

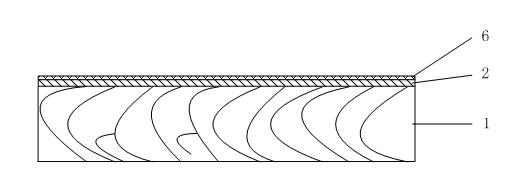

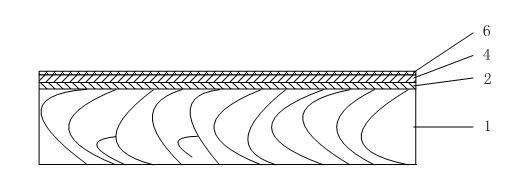

[0008] Specific implementation mode one: the following combination figure 1 This embodiment will be specifically described. A paint-free decorative composite board made under low temperature and low pressure conditions, which includes a base plate 1, which also includes an upper impregnated melamine wood grain paper layer 6, one side of the base plate 1 and the upper impregnated melamine wood grain paper layer 6 are laminated together Fixing, the above impregnated melamine wood grain paper layer 6 is realized under low temperature and low pressure conditions by using a melamine adhesive for curing and impregnating the impregnated wood grain paper. The processing condition is 1.0Mpa.

[0009] The upper impregnated melamine wood-grain paper layer 6 in this embodiment is realized by impregnating the wood-grain paper with a self-developed low-temperature curing impregnated melamine adhesive. Make the impregnated melamine-impregnated wood grain paper achieve better leveling and c...

specific Embodiment approach 2

[0012] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the substrate 1 is blockboard or plywood.

[0013] The substrate 1 in this embodiment is blockboard or plywood. The blockboard is made of high-quality northeast poplar, and the humidity of the board is kiln-dried to 6-12%, and the board is seamlessly assembled by vertical and horizontal machines. Splicing to improve the firmness and connection strength of the board.

specific Embodiment approach 3

[0014] Specific embodiment three: the difference between this embodiment and specific embodiment one is that the composition of the melamine adhesive for low-temperature curing dipping is formaldehyde, melamine, urea, water, and the mass ratio of the four materials is 6:3 :3:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com