Unfired cigarette heating device

A non-combustible, cigarette technology, applied in tobacco, smoker's supplies, applications, etc., can solve the problems of under-reaching, high temperature, and burning cigarettes, and achieve the effects of not falling easily, lowering the heating temperature, and eliminating potential safety hazards Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

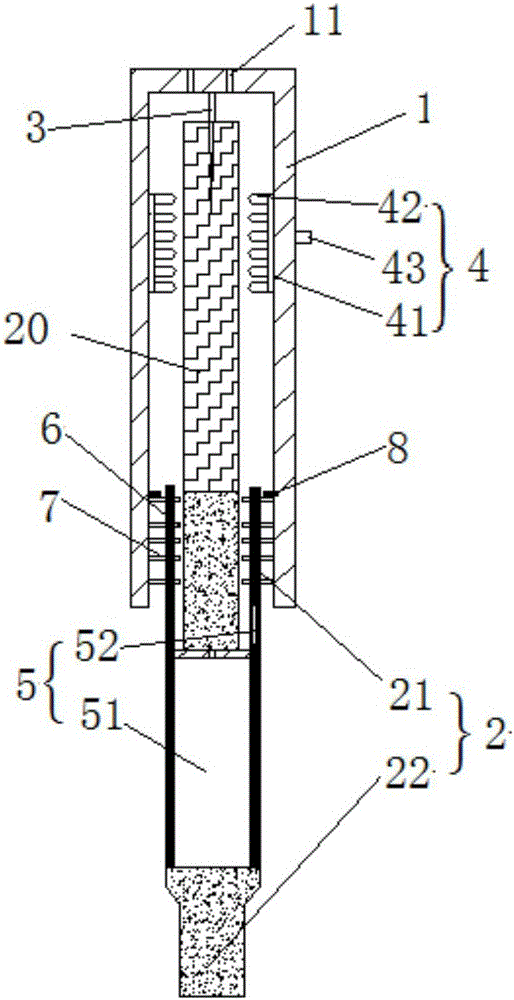

[0040] Such as figure 1 As shown, a pen cap-type non-combustion heating cigarette device of the present invention includes a heating jacket 1 and a circuit control carrier 2, a cavity inside the heating jacket 1, and a vent hole 11 is designed on the wall to be responsible for air intake, and the heating jacket 1 has a piercing heating needle accounting for 1 / 3 of the length of the entire cigarette, an annular external heating structure and a leak-proof silicone protrusion 8, and the circuit control carrier 2 is tightly combined with the silicone protrusion 8 of the heating jacket 1. The cigarette holder has a 20mm cigarette storage cavity, and the annular external heating structure is placed in the middle 1 / 3 of the entire heating jacket through the position regulator 43 . Then put the filter rod of the traditional cigarette into the middle of the cigarette storage cavity, cover the heating jacket, clamp the cigarette, and finally suck it through the suction part.

Embodiment 2

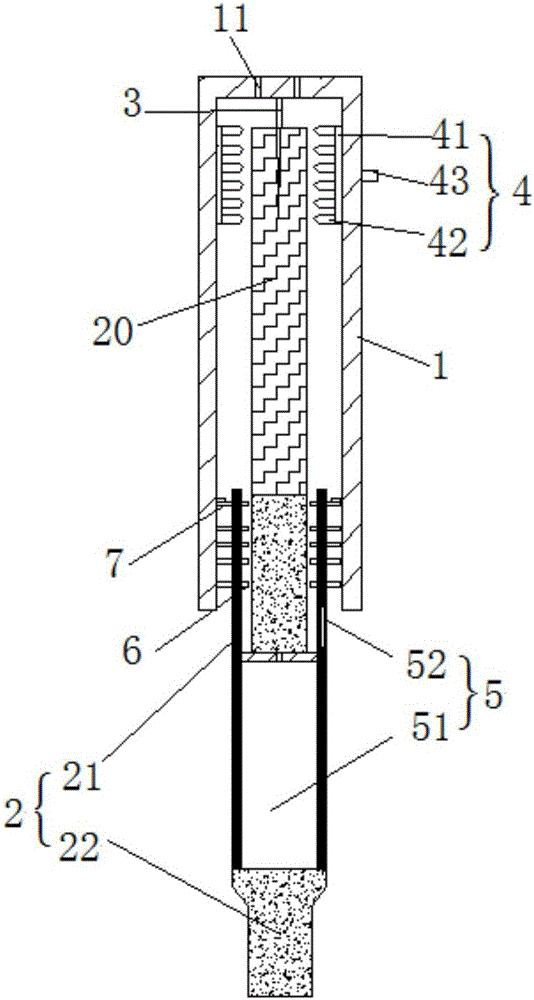

[0042] Such as figure 2 As shown, a pen cap-type non-combustion heating cigarette device of the present invention includes a heating jacket 1 and a circuit control carrier 2, a cavity inside the heating jacket 1, and a vent hole 11 is designed on the wall to be responsible for air intake, and the heating jacket 1 has a piercing heating needle accounting for 1 / 3 of the length of the entire cigarette, an annular external heating structure and a leak-proof silicone protrusion 8, and the circuit control carrier 2 is tightly combined with the silicone protrusion 8 of the heating jacket 1. The cigarette holding part has a 10mm cigarette storage cavity, and the annular external heating structure is placed on the upper 1 / 3 part of the entire heating jacket through the position regulator 43 . Then put the filter rod of the traditional cigarette into the middle of the cigarette storage cavity, cover the heating jacket, clamp the cigarette, and finally suck it through the suction part. ...

Embodiment 3

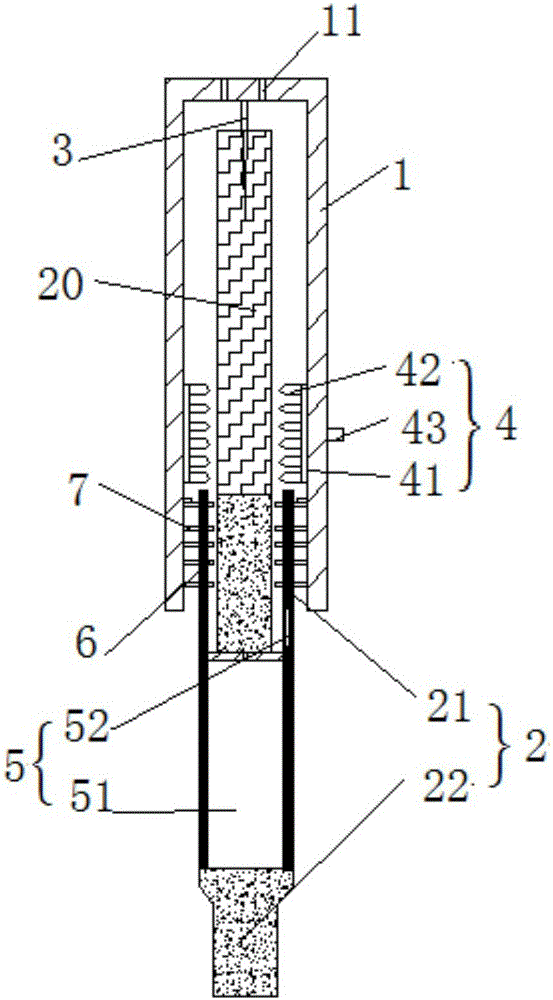

[0044] Such as figure 2 As shown, a pen cap-type non-combustion heating cigarette device of the present invention includes a heating jacket 1 and a circuit control carrier 2, a cavity inside the heating jacket 1, and a vent hole 11 is designed on the wall to be responsible for air intake, and the heating jacket 1 has a piercing heating needle accounting for 1 / 4 of the length of the entire cigarette, a ring-shaped external heating structure, and a leak-proof silicone protrusion 8. The circuit control carrier 2 is tightly combined with the silicone protrusion 8 of the heating jacket 1. The cigarette holding part has a 10mm cigarette storage cavity, and the annular external heating structure is placed in the lower 1 / 4 part of the entire heating jacket through the position regulator 43 . Then put the filter rod of the traditional cigarette into the middle of the cigarette storage cavity, cover the heating jacket, clamp the cigarette, and finally suck it through the suction part. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com