Technological condition for preparing antihypertensive peptide from northeast China juglans mandshurica maxim kernel protein by employing enzymatic method

A blood pressure-lowering peptide, an enzymatic preparation technology, applied in the field of enzymatic preparation of Northeast walnut catalpa seed protein blood pressure-lowering peptide, to achieve the effect of simple process operation, cost saving, and good resolubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

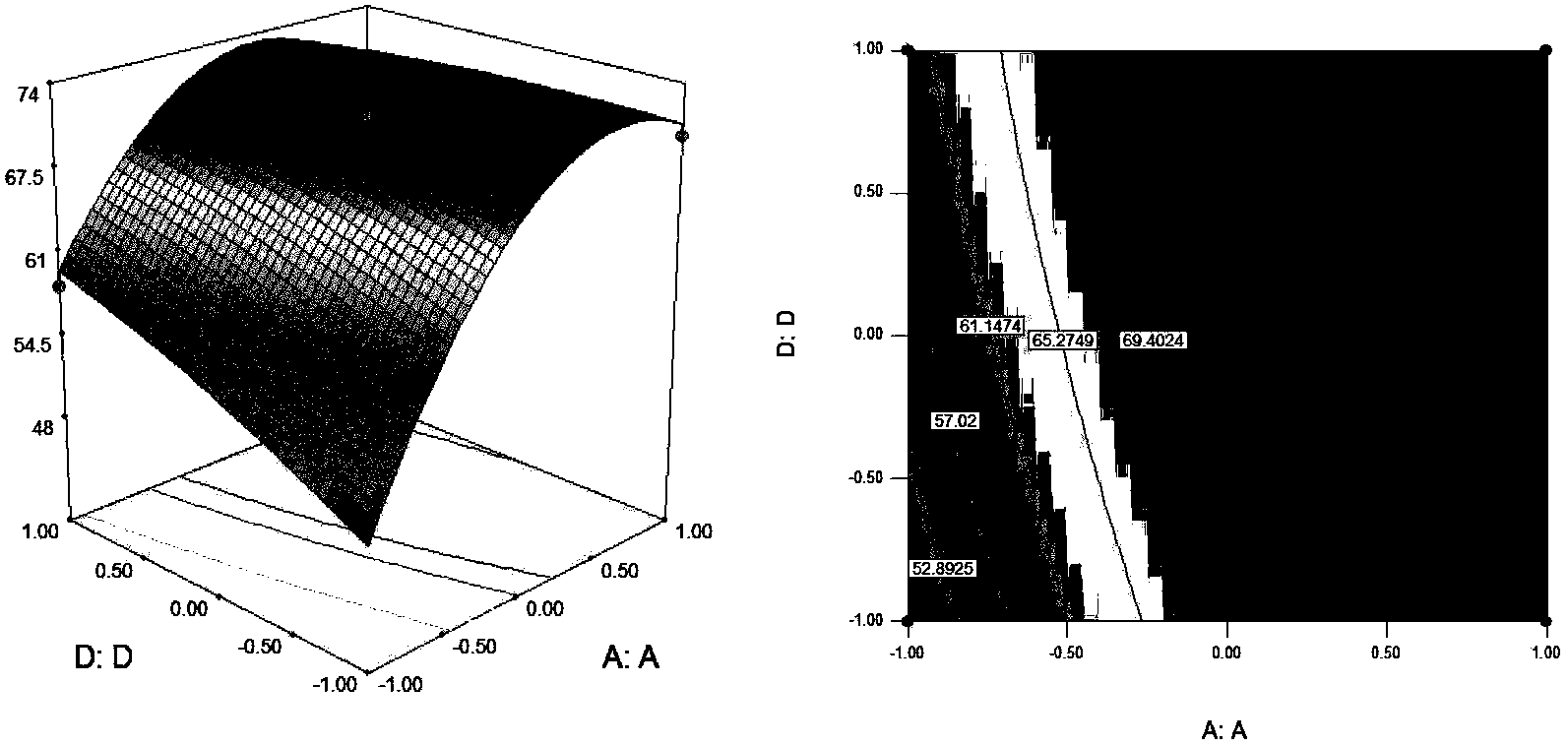

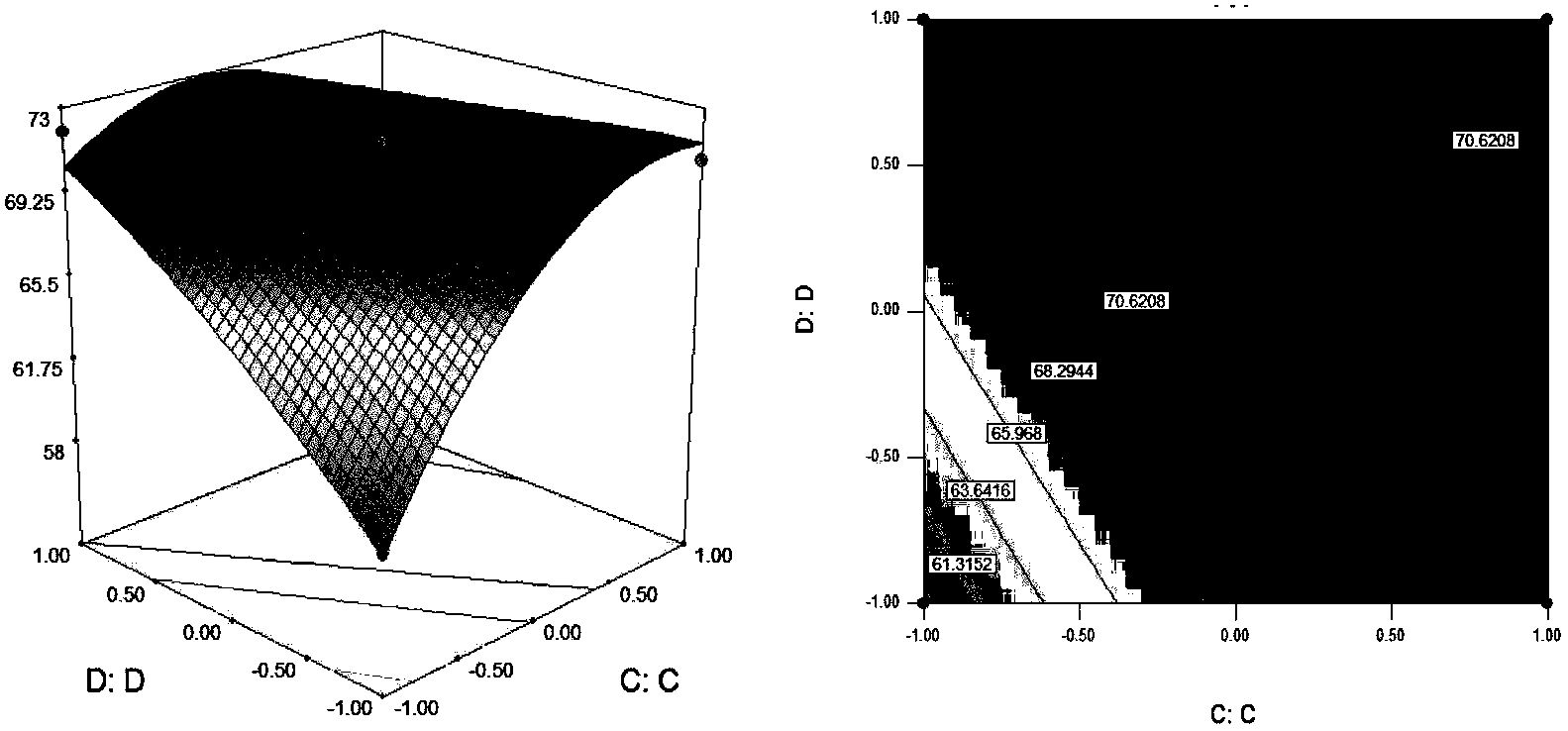

Method used

Image

Examples

Embodiment 1

[0031] Add alkaline protease to 100ml of 2% Northeast Juglans catalpa seed protein solution, enzymolysis at 50°C for 3 hours, the amount of enzyme added is 5000U / g substrate, the pH of enzymolysis is 8, and the enzymolysis process is adjusted with 0.1mol / L NaOH solution The corresponding pH was controlled, and after enzymolysis, the enzyme was inactivated in a boiling water bath at 100°C for 15 minutes; the enzymolysis solution was centrifuged at 4000r / min for 10 minutes, the degree of hydrolysis of the supernatant was 25.784%, and the ACE inhibition rate was 61.135%. The supernatant was subjected to ultrafiltration under the conditions of a pressure of 0.2 MPa, a temperature of 30° C., a permeate flow rate of 2.5 L / h, and a molecular weight intercepted by ultrafiltration of 5000 Da. The Northeast Juglans catalpa seed protein hypotensive peptide obtained after the permeate is concentrated and freeze-dried is a finished product in the form of light yellowish brown powder.

[00...

Embodiment 2

[0043] Add alkaline protease to 100ml of 2% Northeast Juglans catalpa seed protein solution, enzymolysis at 50°C for 4 hours, the amount of enzyme added is 5000U / g substrate, the pH of enzymolysis is 8, and the enzymolysis process is adjusted with 0.1mol / L NaOH solution The corresponding pH was controlled, and after enzymolysis, the enzyme was inactivated in a boiling water bath at 100°C for 15 minutes; the enzymolysis solution was centrifuged at 4000r / min for 10 minutes, and the degree of hydrolysis of the supernatant was 27.567%, and the ACE inhibition rate was 62.375%. The supernatant was subjected to ultrafiltration under the conditions of a pressure of 0.2 MPa, a temperature of 30° C., a permeate flow rate of 2.5 L / h, and a molecular weight intercepted by ultrafiltration of 5000 Da. The Northeast Juglans catalpa seed protein hypotensive peptide obtained after the permeate is concentrated and freeze-dried is a finished product in the form of light yellowish brown powder.

Embodiment 3

[0045] Add alkaline protease to 100ml of 2% Chinese catalpa seed protein solution, add alkaline protease, and enzymolyze at 56°C for 4 hours, the amount of enzyme added is 5880U / g substrate, the pH of enzymolysis is 8.2, and the enzymolysis process is adjusted with 0.1mol / L NaOH solution The corresponding pH was controlled, and after enzymolysis, the enzyme was inactivated in a boiling water bath at 100°C for 15 minutes; the enzymolysis solution was centrifuged at 4000r / min for 10 minutes, the degree of hydrolysis of the supernatant was 29.03%, and the ACE inhibition rate was 72.48%. The supernatant was subjected to ultrafiltration under the conditions of a pressure of 0.2 MPa, a temperature of 30° C., a permeate flow rate of 2.5 L / h, and a molecular weight intercepted by ultrafiltration of 5000 Da. The Northeast Juglans catalpa seed protein hypotensive peptide obtained after the permeate is concentrated and freeze-dried is a finished product in the form of light yellowish brow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com