Crosslinked polysiloxane/acrylic ester compound emulsion, and preparation method and application thereof

A technology for cross-linking polysiloxane and polyacrylate emulsion, applied in latex paint, coating and other directions, can solve the problems of high preparation cost, high equipment requirements, difficult polymerization process, etc., and achieves simple operation and high safety. , the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

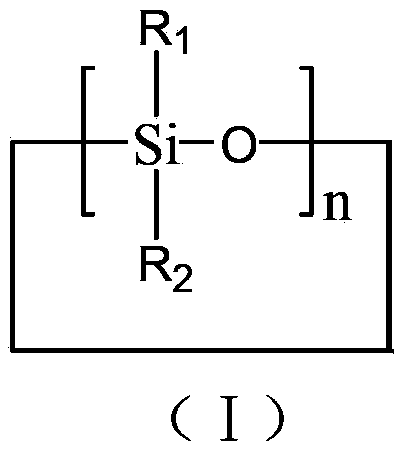

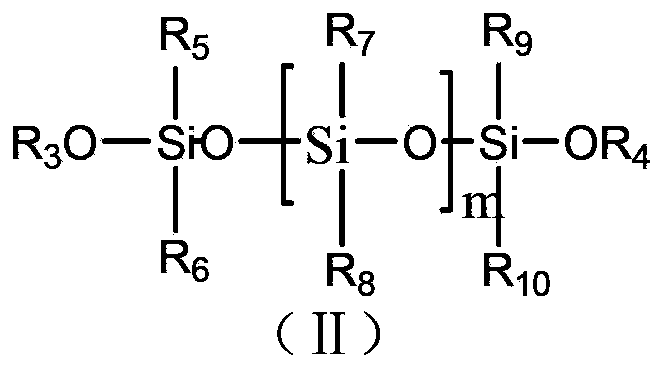

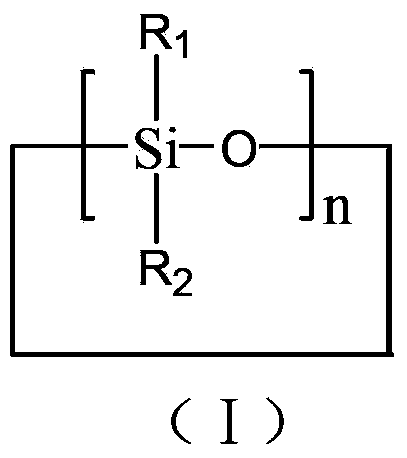

Method used

Image

Examples

Embodiment 1

[0045] (1) Add 0.7g of octadecyltrimethylammonium chloride and 0.5g of isomeric tridecyl alcohol polyoxyethylene ether (the number of moles of added ethylene oxide = 7) to a 500mL glass, and use 118g of water Dissolve, after fully dissolved, add 12g octamethylcyclotetrasiloxane (D4), stir to make it evenly mixed, and then shear at high speed (5000 rpm) in a shear emulsification mixer for 10 minutes to form organosiloxane alkane monomer pre-emulsion; transfer the organosilicon monomer pre-emulsion to a high-pressure homogenizer, and homogenize once under a homogenizing pressure of 30Mpa to form an organosiloxane monomer emulsion.

[0046] (2) Heat the organosiloxane monomer emulsion to 80°C, add 10g of 10wt% potassium hydroxide solution, react for 6 hours, cool to 40°C, add 1.2g of octadecyltrimethylammonium chloride and 1.2g of four Ethoxysilane, polymerized for 3 hours, cooled to 25°C, then added 1g of acetic acid to neutralize the emulsion to neutral, filtered and discharged...

Embodiment 2

[0050] (1) Add 1.4g of octadecyltrimethylammonium chloride and 1g of isomeric tridecyl alcohol polyoxyethylene ether (the number of moles of added ethylene oxide = 7) into a 500mL glass, and dissolve it in 118g of water , after fully dissolved, add 24g of octamethylcyclotetrasiloxane (D4), stir to make it evenly mixed, and then shear at high speed (5000 rpm) in a shear emulsification mixer for 10 minutes to form organosiloxane Monomer pre-emulsion: transfer the organosilicon monomer pre-emulsion to a high-pressure homogenizer, and homogenize once under a homogenizing pressure of 40Mpa to form an organosiloxane monomer emulsion.

[0051] (2) Heat the organosiloxane monomer emulsion to 90°C, add 20g of 10wt% potassium hydroxide solution, react for 6 hours, cool to 40°C, add 1.2g of octadecyltrimethylammonium chloride and 2.4g of four Ethoxysilane, polymerized for 3 hours, cooled to 20°C, then neutralized by adding 2g of acetic acid, and filtered out to obtain a cross-linked poly...

Embodiment 3

[0055] (1) Add 3g of octadecyltrimethylammonium chloride and 2g of isomeric tridecyl alcohol polyoxyethylene ether (the number of moles of added ethylene oxide = 7) into a 500mL glass, dissolve it in 118g of water, After fully dissolved, add 36g of octamethylcyclotetrasiloxane (D4), stir to make it evenly mixed, and then shear at high speed (5000 rpm) in a shear emulsification mixer for 10 minutes to form organosiloxane body pre-emulsion; transfer the organosilicon monomer pre-emulsion to a high-pressure homogenizer, and homogenize once under a homogenizing pressure of 20Mpa to form an organosiloxane monomer emulsion.

[0056] (2) Heat the organosiloxane monomer emulsion to 70°C, add 20g of 10wt% potassium hydroxide solution, react for 6 hours, cool to 40°C, add 3.6g of octadecyltrimethylammonium chloride and 3.6g of four Ethoxysilane, polymerized for 3 hours, cooled to 25°C, then neutralized by adding 2g of acetic acid, and filtered out to obtain a cross-linked polysiloxane e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com