Synthetic method of 1, 3-dioxane type organic compounds

A technology of dioxane, organic compound, applied in 1 field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

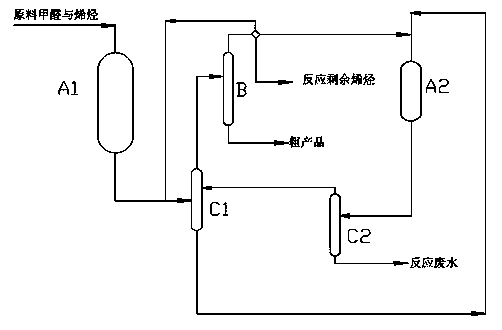

[0023] Example 1: (a) Use deionized 37wt% industrial formaldehyde and butane containing 50wt% 1-butene as raw materials, and send them into the first-stage catalytic fixed-bed reactor A1 at a molar ratio of 1.8:1, and the reaction temperature is 100 ℃, the reaction pressure is 2MPa, and the reaction is catalyzed by macroporous strongly acidic polystyrene cation exchange resin;

[0024] (b) The reaction liquid extracted from the first-stage catalytic fixed-bed reactor A1 is sent to the first-stage extraction and separation tower C1, and the extracted oil phase is sent to the separation tower B for separation. The temperature of the tower bottom is 163 ° C, and the temperature of the top of the tower is 48 ° C. The pressure is 0.45MPa; the extracted aqueous phase is sent to the second-stage catalytic fixed-bed reactor A2, the reaction temperature is 105°C, and the reaction pressure is 2MPa, and the reaction is catalyzed by macroporous strongly acidic polystyrene cation exchange...

Embodiment 2

[0028] Example 2 (a) With deionized 37wt% industrial formaldehyde and butane containing 50wt% 2-butene as raw material, send it into the first-stage catalytic fixed-bed reactor A1 at a molar ratio of 1.8:1, and the reaction temperature is 100°C, the reaction pressure is 2MPa, and the reaction is catalyzed by macroporous strongly acidic polystyrene cation exchange resin;

[0029] (b) The reaction liquid extracted from the first-stage catalytic fixed-bed reactor A1 is sent to the first-stage extraction and separation tower C1, and the mixed material that is left over from the reaction and separated and replenished by the separation tower B is used for extraction and separation, and the resulting oil phase is extracted Sent to the separation tower B for separation, the temperature of the tower kettle is 163°C, the temperature of the tower top is 48°C, and the pressure is 0.45MPa; the extracted aqueous phase is sent to the second-stage catalytic fixed-bed reactor A2, the reaction...

Embodiment 3

[0033] Example 3 : : (a) Use deionized 37wt% industrial formaldehyde, butane containing 25wt% 1-butene and 25wt% 2-butene as raw materials, and send them into the first-stage catalytic fixed-bed reactor at a molar ratio of 1.8:1 A1, the reaction temperature is 100°C, the reaction pressure is 2MPa, and the reaction is catalyzed by macroporous strongly acidic polystyrene cation exchange resin;

[0034] (b) The reaction liquid extracted from the first-stage catalytic fixed-bed reactor A1 is sent to the first-stage extraction and separation tower C1, and the mixed material that is left over from the reaction and separated and replenished by the separation tower B is used for extraction and separation, and the resulting oil phase is extracted Sent to the separation tower B for separation, the temperature of the tower kettle is 163°C, the temperature of the tower top is 48°C, and the pressure is 0.45MPa; the extracted aqueous phase is sent to the second-stage catalytic fixed-bed r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com