Synthetic method for Cu2ZnSnS4 photosensitive thin-film material

A copper-zinc-tin-sulfur and photosensitive thin film technology, applied in tin compounds, chemical instruments and methods, inorganic chemistry, etc., can solve problems such as reducing the possibility of large-scale commercial production, and achieve easy control of film thickness, good consistency and The effect of uniformity and fast growth rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The preparation method step of copper-zinc-tin-sulfur film of the present invention:

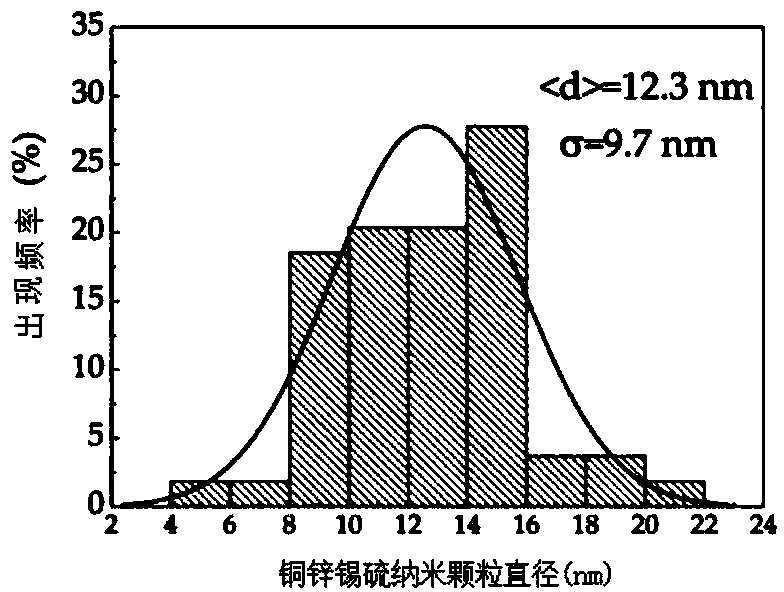

[0026] 1) Preparation of copper-zinc-tin-sulfur nanoparticle solution

[0027] Step 1. Weigh copper sulfate pentahydrate crystals, zinc sulfate heptahydrate crystals, tin sulfate dihydrate crystals, and sodium sulfide nonahydrate crystals with a molar ratio of 2:1:1:4 for analytical purity.

[0028] Step 2, adding the copper sulfate pentahydrate crystals weighed in step 1, zinc sulfate heptahydrate crystals, and tin sulfate dihydrate crystals into an appropriate amount of ethylene glycol of analytical purity to obtain a zinc sulfate molar concentration of 5-15 millimoles / liter of solution A. The organic solvent here can be selected from any one of ethylene glycol, ethanol, methanol, propanol, butanol, tert-butanol, isopropanol, isoamyl alcohol and n-butanol, but is not limited thereto;

[0029] Step 3, adding the sodium sulfide nonahydrate crystals taken by step 1 into an appropri...

Embodiment

[0042]Step 1, the copper sulfate pentahydrate crystal of analytical purity, the zinc sulfate heptahydrate crystal of analytical purity, the tin sulfate dihydrate crystal are joined in the ethylene glycol of analytical purity in the order of 2:1:1 with molar ratio, Making zinc sulfate molar concentration is the solution A of 10 mmol / liter;

[0043] Step 2. Mix the solution A obtained in step 1 and place it in a 100-ml small flask, heat it to 190° C., and simultaneously feed high-purity argon (purity>99.99%) into the solution at a flow rate of 2 ml / min;

[0044] Step 3, dissolving the sodium sulfide nonahydrate crystal of analytical purity in 10 milliliters of ethylene glycol of analytical purity (equal with the ethylene glycol amount used in step 1), described copper sulfate pentahydrate crystal, sulfuric acid heptahydrate The molar ratio of zinc crystal, tin sulfate dihydrate crystal and sodium sulfide nonahydrate crystal is 2:1:1:4;

[0045] Step 4, adding the solution obtai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com