LED curing light source for digital ink jetting

A digital inkjet and light source technology, applied in printing, printing devices, etc., can solve the problems of physical injury of employees, high and low operating costs, and inability to control independently or in combination, so as to improve the stability of power output, prolong the service life of LED, The effect of improving equipment utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

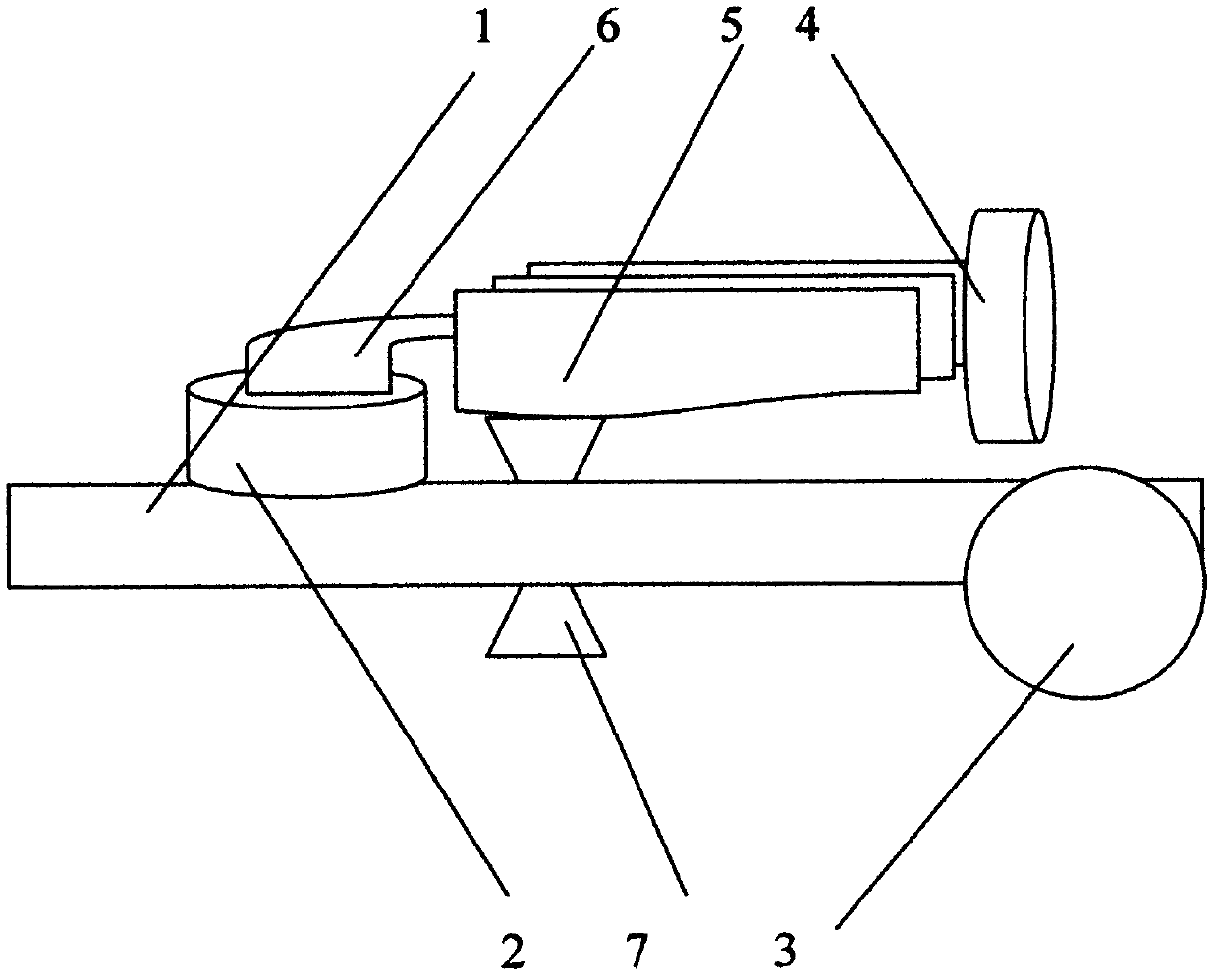

[0014] exist figure 1 Among them, an LED curing light source for digital inkjet, the LED curing lamp 2 is installed on the left side of the ink cart through the connecting piece 7, and the LED lamp follows the movement of the ink cart in real time to instantly cure the pattern.

[0015] A group of lamp beads 5 are installed at the lower end of the LED curing lamp 2, and the lamp beads 5 instantly solidify the ink ejected from the nozzle. A heat sink 3 is installed above the curing lamp, and two fans 4 are installed above the heat sink 3. When the LED When the curing lamp 2 is energized and turned on, the fan 4 and the lamp bead 5 are turned on at the same time, the curing ink is activated by the heat emitted by the lamp bead 5, and the heat sink 3 is dissipated by the fan 4 above the lamp bead 5 of.

Embodiment 2

[0017] Such as figure 1 As shown, a LED curing light source for digital inkjet, its light curing control system is composed of connector 7, ink cart 1, heat sink 3 and six-core wire 6, and controls the LED for digital inkjet through an induction switch The connector 7 of the curing light source feeds back the pressure in the hydraulic system to the connector 7 through the heat sink 3, and then the lamp bead 5 feeds back the speed of the ink cart 1 to the connector 7, and the control signal is processed by the connector 7 Send it to the ink car 1 to adjust the output pressure and flow of the six-core wire 6.

Embodiment 3

[0019] The connection method between the motor and the oil pump: such as figure 1 As shown, the photocuring control system of the LED curing light source for digital inkjet includes an ink cart 1 and a six-core wire 6, and the six-core wire 6 of the ink cart 1 is connected to the LED curing lamp 2 and the fan 4 through the six-core wire 6, and the fan 4 Insert the six-core wire 6.

[0020] The LED curing lamp 2 adopts LED curing light source.

[0021] Described fan 4 adopts motor fan 4, is connected better like this, more stable.

[0022] An LED curing light source for digital inkjet, because it includes the above-mentioned light curing control system, it can be adjusted in real time according to the working conditions of the entire LED curing light source for digital inkjet, so that it can most appropriately meet the actual needs of the system and avoid excessive The waste of large ink flow occurs, which saves the energy of the LED curing light source and the volume of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com