Electric heating internal recirculating air continuous baking frying machine

An internal circulation, electric heating technology, applied in the direction of roaster/barbecue grid, kitchen utensils, home utensils, etc., can solve the problems of low work efficiency, difficult to achieve industrial standardization, automatic production, low control accuracy, etc., to improve the temperature The effect of measuring accuracy and control accuracy, improving the quality of food processing, and improving the working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

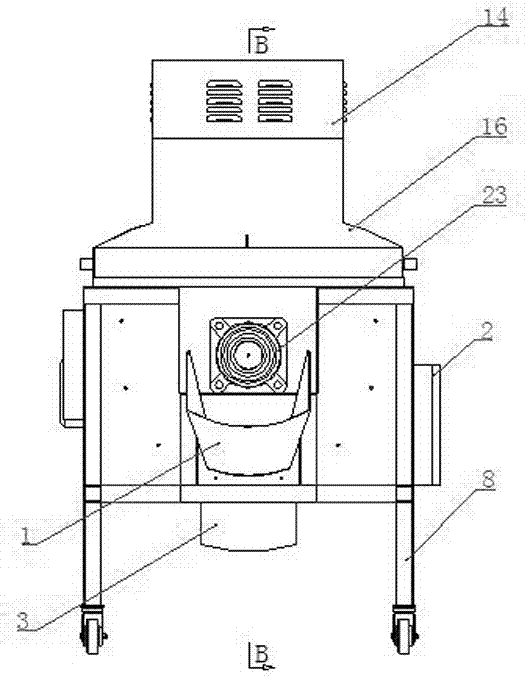

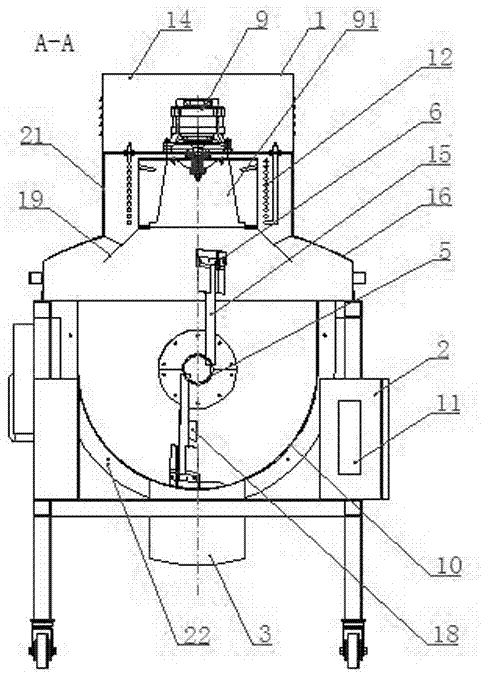

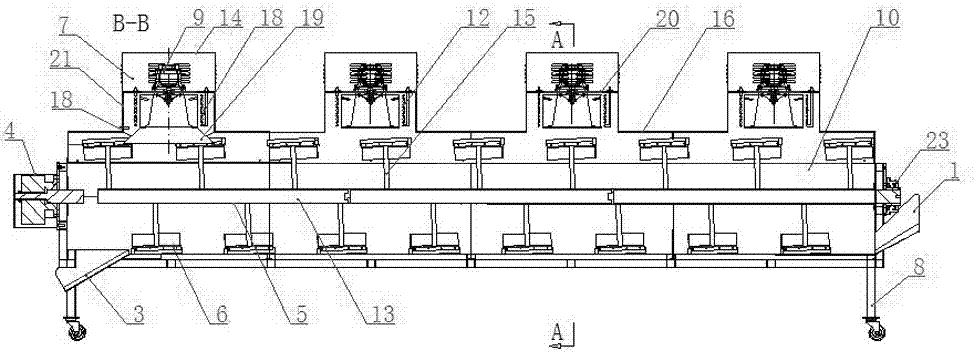

[0019] see Figure 1 ~ Figure 4 , the present invention is an electric heating internal circulating air continuous baking and frying machine, which is characterized in that it includes a frame 8, a U-shaped groove 10, a stirring device 5, a circulating hot air device 7 and a machine cover 16, and the bottom is in the shape of a circular arc The U-shaped groove 10 is supported on the frame 8, and a machine cover 16 with end caps is installed on the top and two ends of the U-shaped groove 10, and a circulating hot air device 7 is installed on the machine cover 16. A stirring device 5 capable of rotating around the axis of the arc of the U-shaped groove 10 is housed in the groove 10; a material inlet 1 and a material outlet 3 are respectively installed on the end covers at both ends of the machine cover 16; An operation panel 2 is installed, and a control circuit 11 is installed in the operation panel 2 for controlling the operation of the complete machine.

[0020] Described ci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com