Rolling method of grain size of stainless steel plates used for controlling thermonuclear fusion reactors

A thermonuclear fusion, stainless steel technology, applied in the field of steel plate rolling, can solve problems such as the inability to meet the thermonuclear experimental reactor, and the coarse grain size of the finished product.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

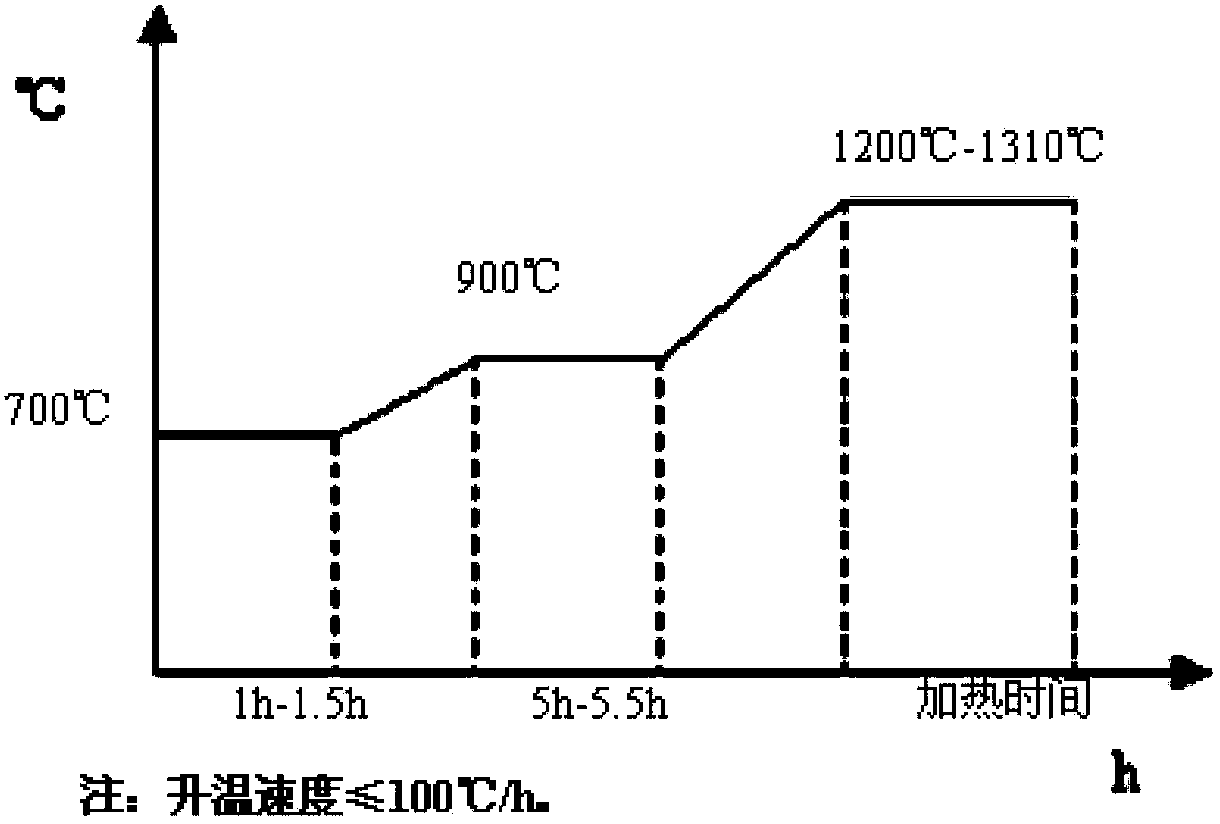

[0030] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings.

[0031] The rolling object of the method is a steel ingot poured by the smelting method. Depending on the requirements of ITER, two types of stainless steel may be used for different applications.

[0032] Steel number: 316L Weight percentage requirements of ingredients:

[0033] C≤0.03%; Si≤0.75%; Mn≤2.00%; P≤0.03%; S≤0.01%; Cr 16.00%-18.00%; Ni 11.00%-14.00%; Mo2.00%-2.50%; %; N 0.06%-0.08%; Nb≤0.10%; Ta≤0.10%; the rest is Fe and unavoidable impurities.

[0034] Steel number: 316LN, weight percentage requirements of ingredients:

[0035] C≤0.03%; Si≤0.75%; Mn≤2.00%; P≤0.03%; S≤0.01%; Cr16.00%-18.50%; Ni 10.00%-14.00%; Mo 2.00%-3.00%; %; N 0.12%-0.17%; Nb≤0.10%; Ta≤0.10%; the rest is Fe and unavoidable impurities.

[0036] The above-mentioned stainless steel can adopt any one or more of electric furnace+VOD+LF smelting method, converter+...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com