Illuminating system of step scanning projection mask aligner

A step-scanning and lighting system technology, applied in the field of lighting systems, can solve problems such as small size of micro-slits, and achieve the effects of reducing processing difficulty, being easy to implement, and improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the embodiments and accompanying drawings, but the protection scope of the present invention should not be limited thereby.

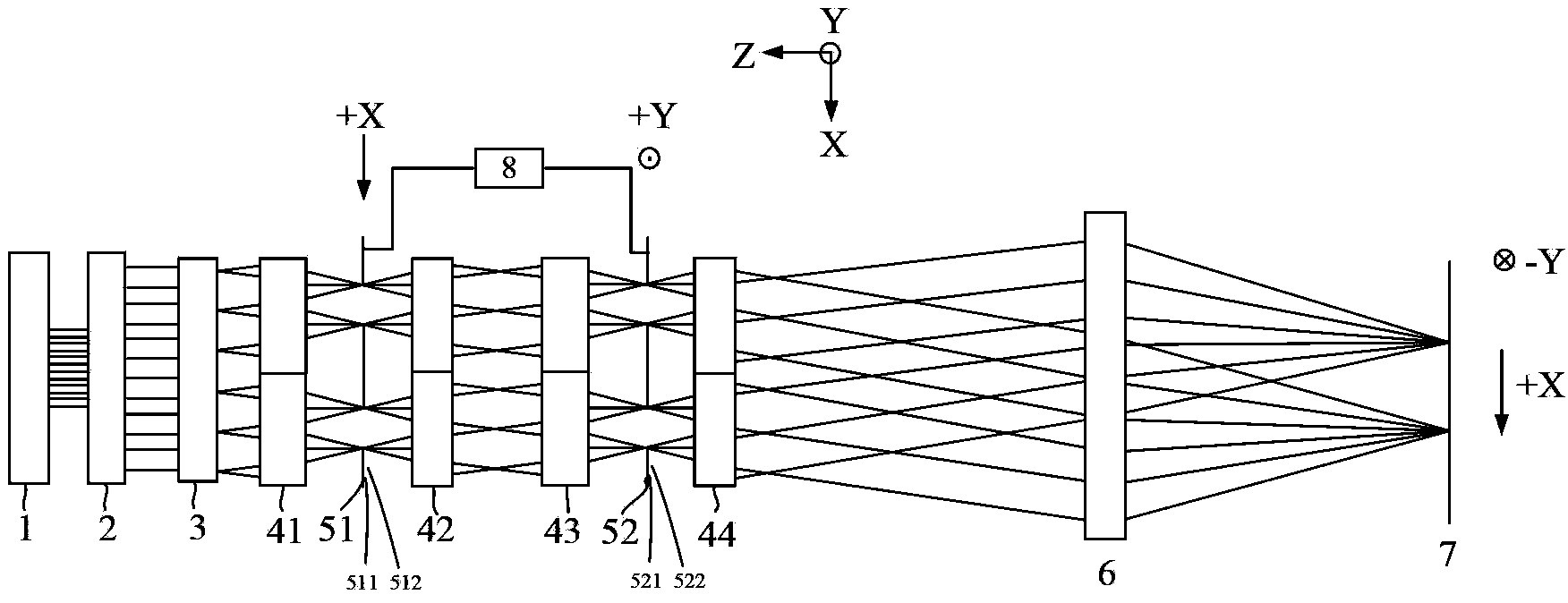

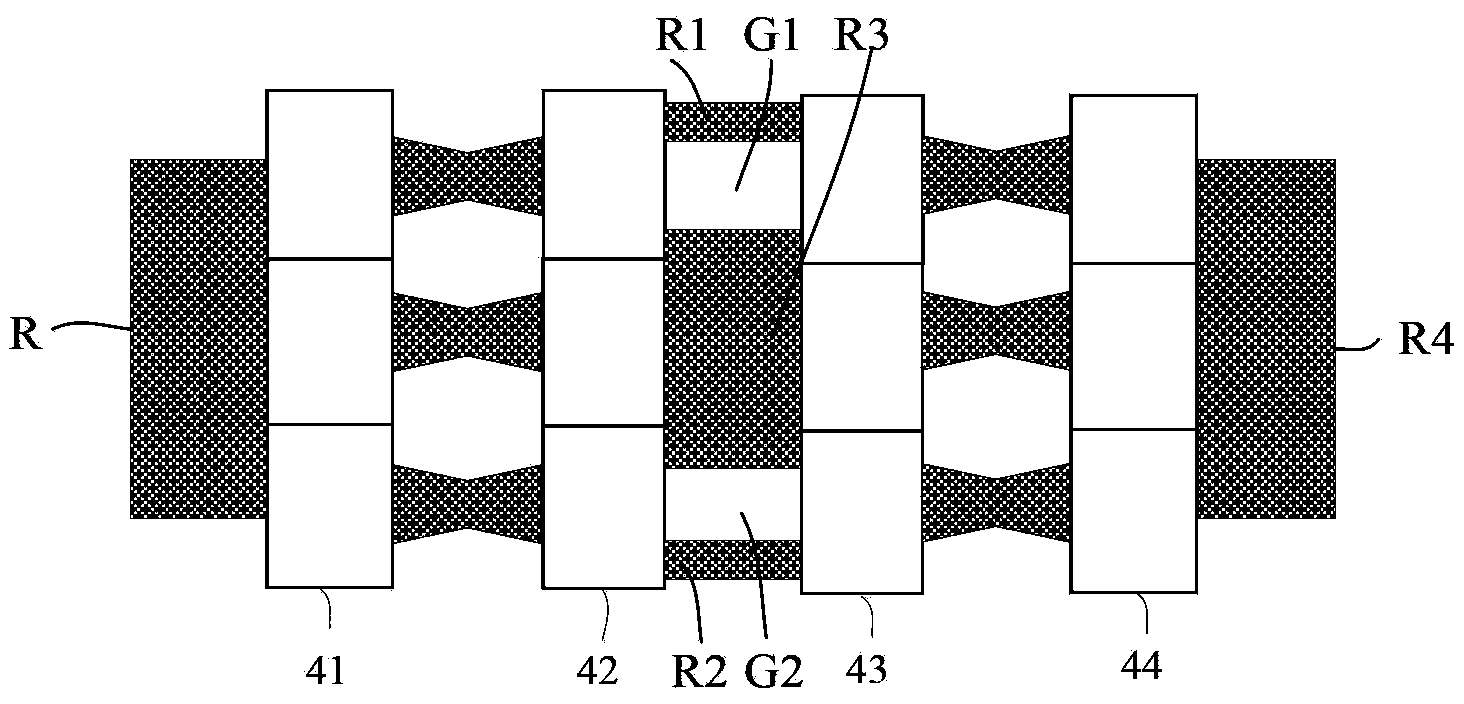

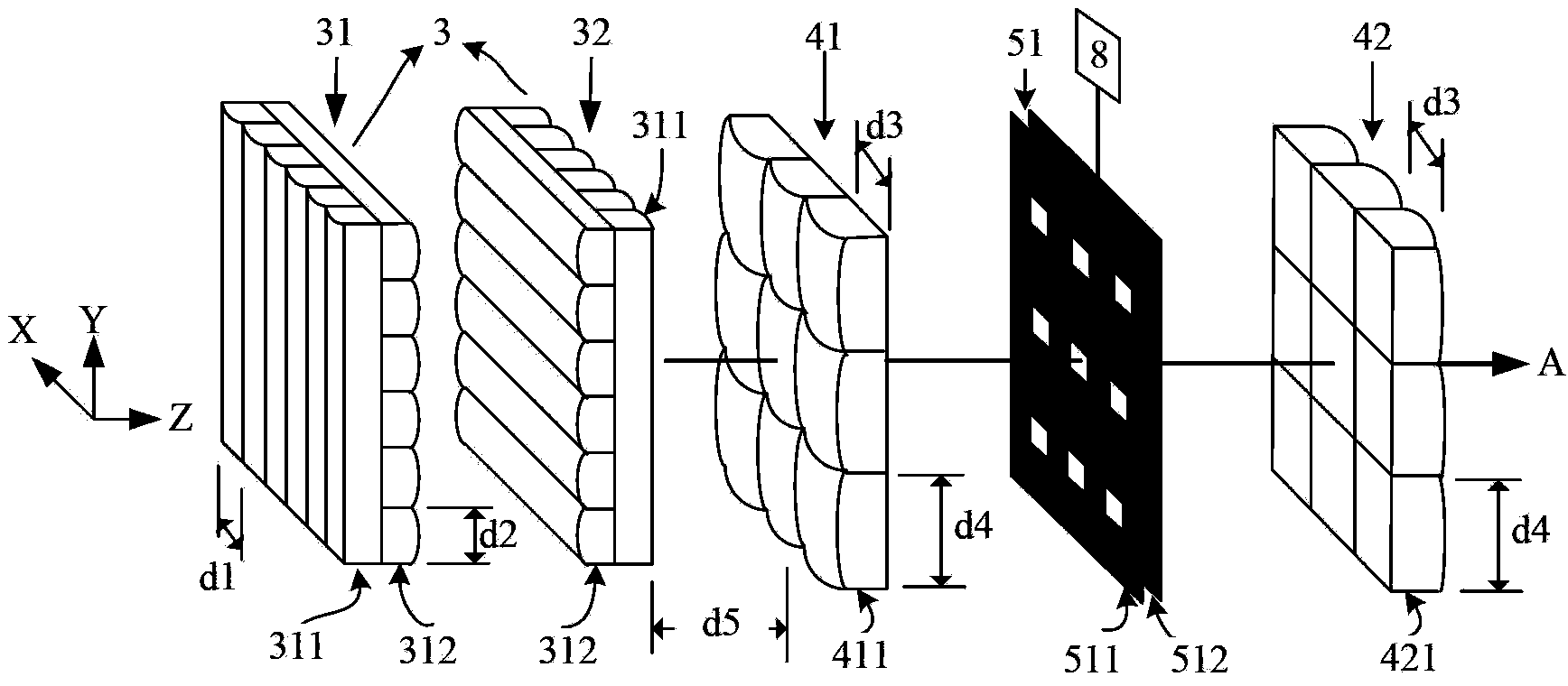

[0023] see first figure 1 , figure 1 It is a structural schematic diagram of the illumination system of the step-and-scan projection lithography machine of the present invention. It can be seen from the figure that the illumination system of the step-and-scan projection lithography machine of the present invention includes a light source 1, a pupil shaping unit 2, a field of view defining unit 3, a first lens array 41, a first slit array 51, and a second lens array 42 , the third lens array 43, the second slit array 52, the fourth lens array 44, the condenser lens 6 and the scanning drive unit 8, and its positional relationship is: the light emitted by the light source 1 passes through the pupil shaping unit 2 and the field of view defining unit successively 3. After the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com