Recyclable vertical steel tube front supporting envelop enclosure and applying method thereof

A technology of enclosure structure and application method, applied in basic structure engineering, excavation, construction, etc., can solve the problems of reducing construction cost, low construction cost, and large impact on the surrounding environment, and achieves overcoming slow construction speed, enhancing stability, economical Sex-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

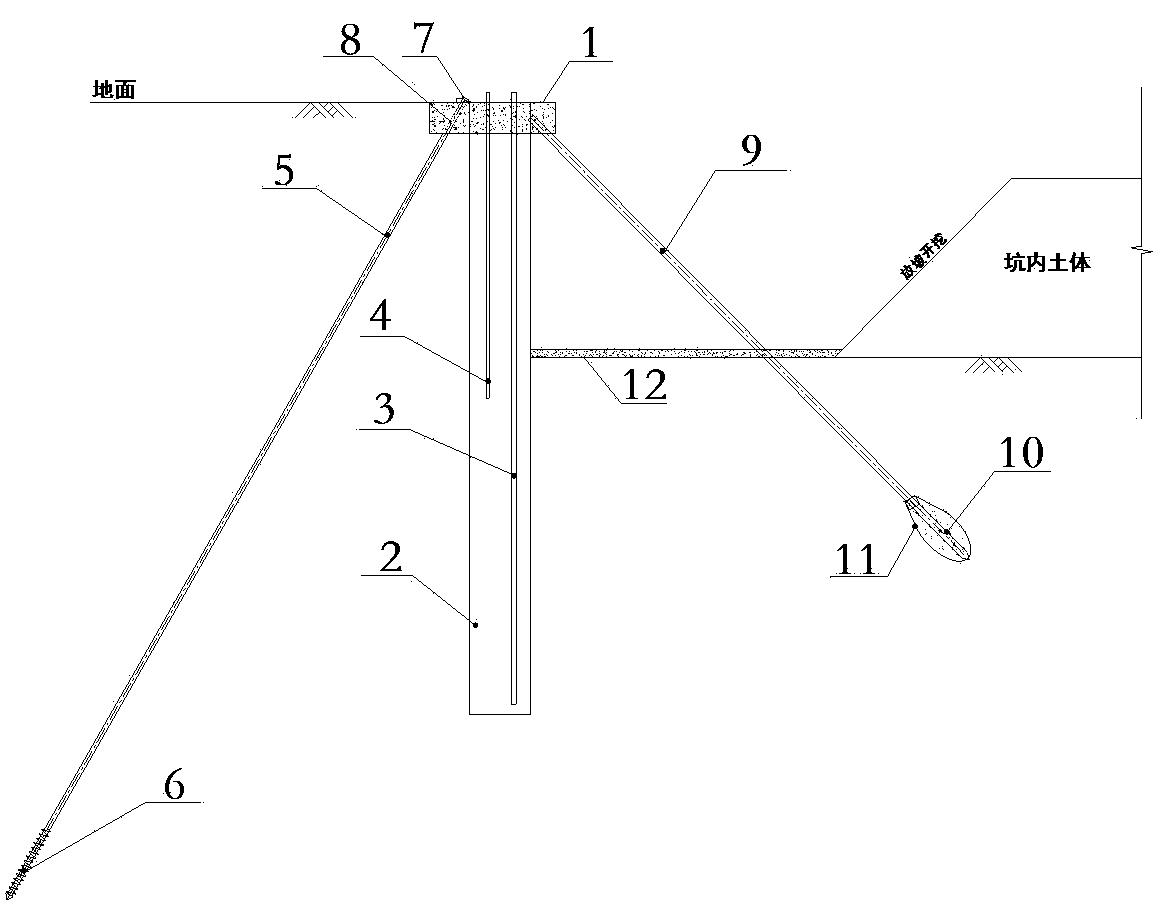

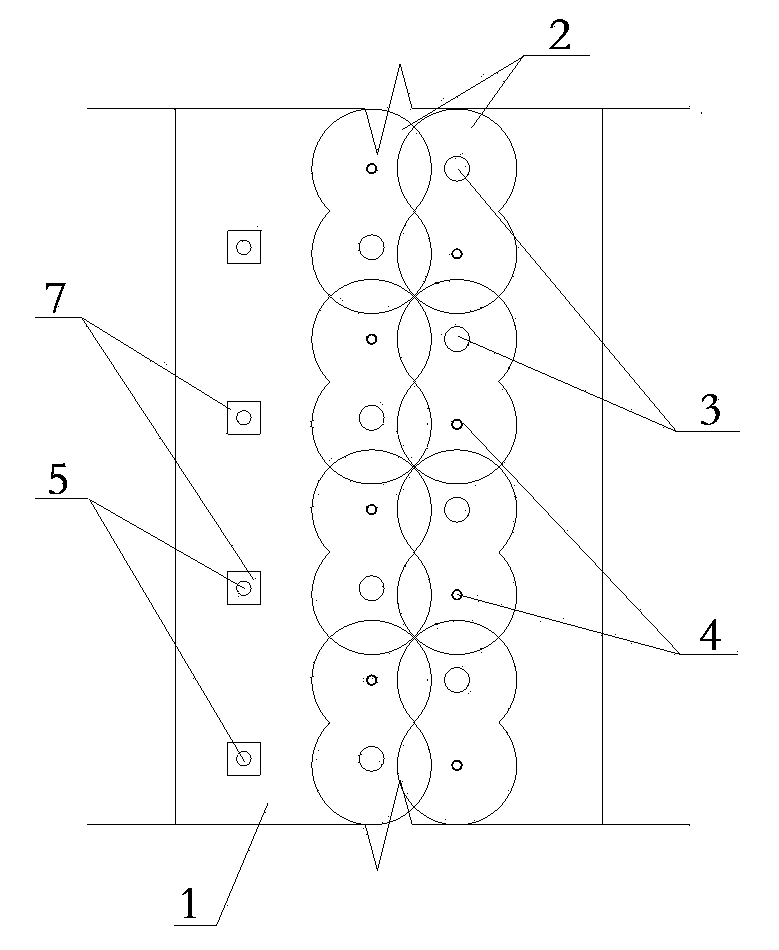

[0022] Example: such as figure 1 , 2 As shown, this embodiment specifically relates to a recyclable upright steel pipe front support enclosure structure for soft soil foundation pits and its application method. Steel pipe 5, middle group steel pipes 3 and 4, inner group steel pipe 9, and reinforcement cushion 12 are combined to form multiple functions of reinforcement, soil retaining and water sealing, restraining soil deformation and enhancing the stability of the foundation pit wall. It can be excavated vertically, avoiding the problem that the conventional sloping excavation method occupies a large area of the site, and at the same time greatly reduces the amount of conventional cement-soil gravity enclosure walls and steel cement-soil mixing walls, and overcomes its slow construction speed and high cost. The quality of the wall is not easy to control and other disadvantages; the steel pipe structure can be easily removed, and it can be recycled after the construction is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com