Preparation method of opal-structure polymer photonic crystal

A technology for structural polymers and photonic crystals, which is applied in crystal growth, chemical instruments and methods, single crystal growth, etc. It can solve the problems of limited application fields, impure products, complicated feeding and heating program control, etc., and achieve a wide range of applications. Foreground effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

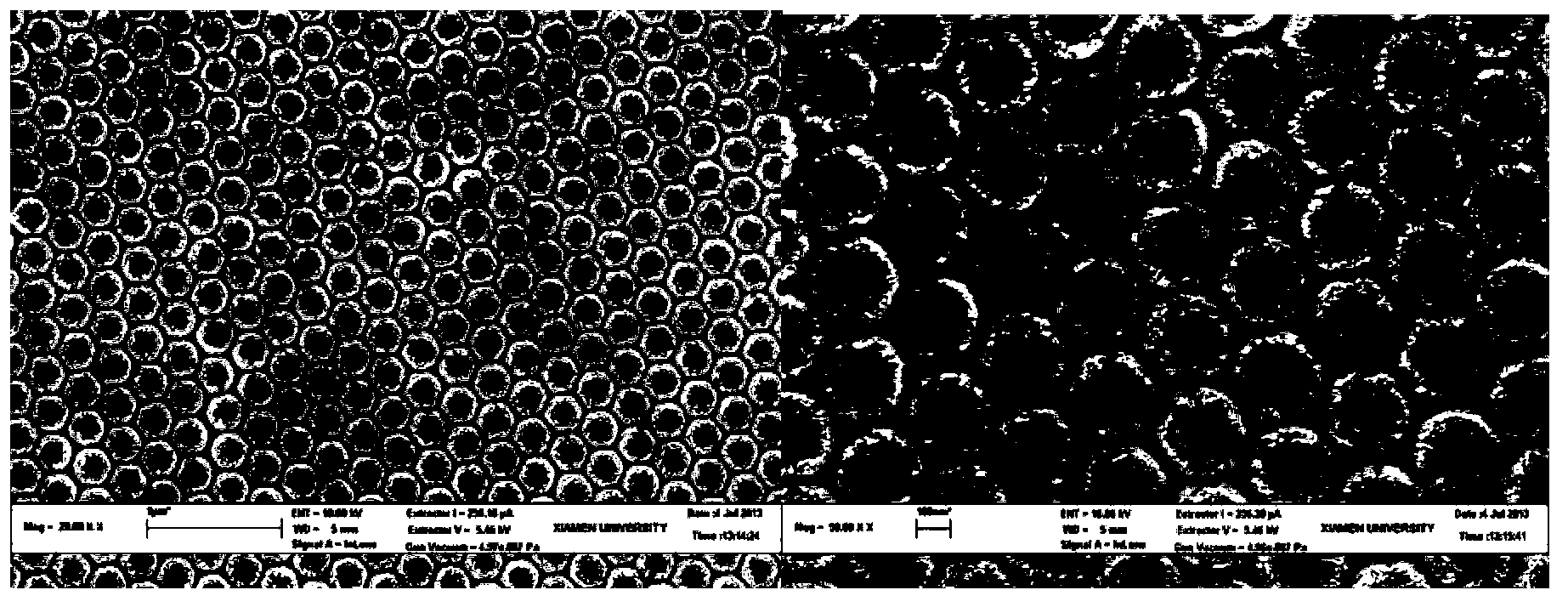

[0025] Add 0.6mL of the hydrophilic monomer glycidyl methacrylate and 2mL of the hydrophobic monomer styrene into a three-necked flask containing 40mL of deionized water and stir for 10min with nitrogen gas, then add an aqueous solution in which 0.08g of potassium persulfate initiator is dissolved, Continue to blow nitrogen, raise the temperature to 80°C, and react for 12 hours to obtain a monodisperse styrene-copolyglycidyl methacrylate (PS-PGMA) microsphere emulsion.

[0026] At room temperature, the obtained monodisperse PS-PGMA polymer microsphere emulsion is applied to a glass slide, and after the water evaporates naturally, the opal structure photonic crystal with a unique color can be obtained.

Embodiment 2~6

[0027] Embodiment 2~6: With the process condition of embodiment 1, change the addition amount of hydrophilic monomer glycidyl methacrylate, synthesize the monodisperse styrene copolymerized glycidyl methacrylate (PS-PGMA) of different particle size ) microsphere emulsion, the results are shown in Table 1.

[0028] At room temperature, apply the monodisperse PS-PGMA polymer microsphere emulsion obtained in Examples 2 to 8 on a glass slide, and wait for the water to evaporate naturally to obtain an opal-structured photonic crystal with a unique color.

[0029] Table 1

[0030]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com