Combined type deacidification and deodorization tower suitable for deodorizing edible oil in oil industry

A technology for deacidification and deodorization, and edible oil, which is applied in the fields of edible oil/fat, fat oil/fat refining, and application, etc., can solve the problems of large gas consumption, edible oil index failing to meet national standards, and long deacidification and deodorization time. To achieve the effect of strong deodorization ability, ensuring sealing and ensuring vacuum degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

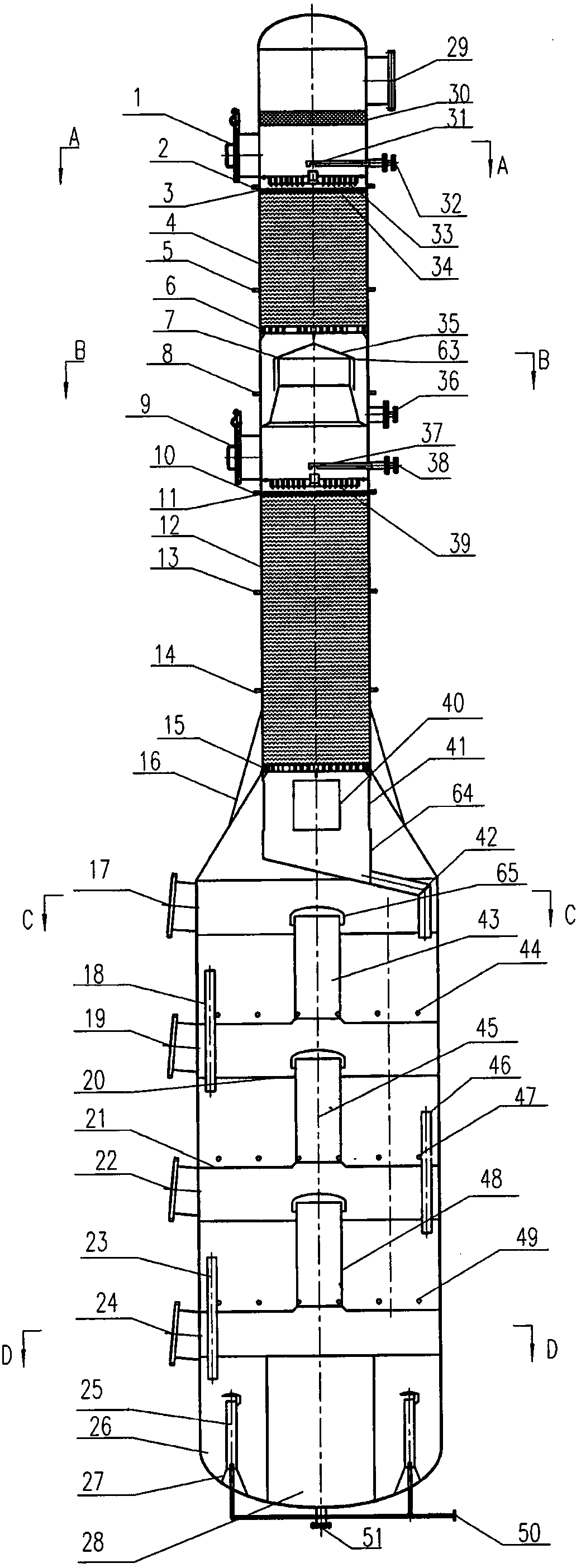

[0023] The present invention is further described below in conjunction with embodiment (accompanying drawing):

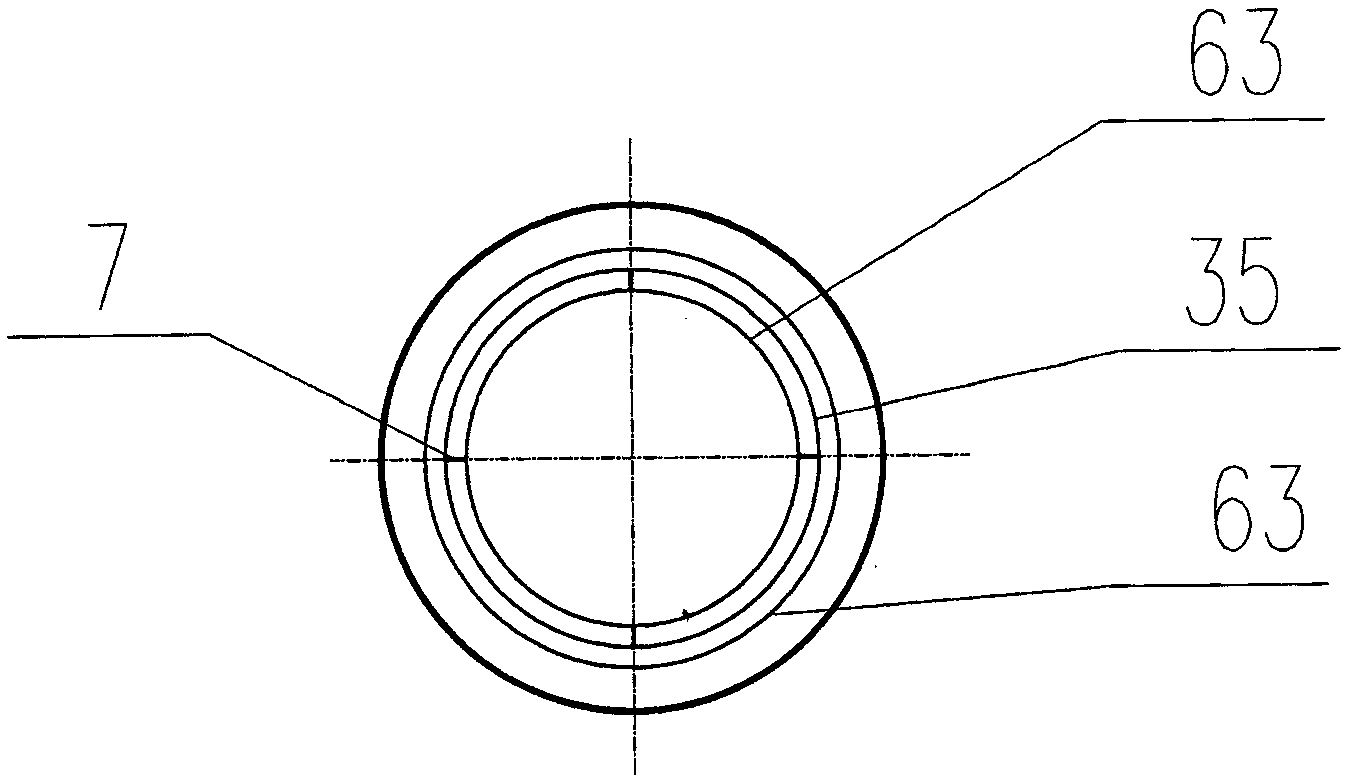

[0024] Such as Figure 1-5 As shown, the present invention is a kind of deodorization tower applicable to the deacidification and deodorization of oils and fats in the oil industry. The tower is divided into four parts from top to bottom. The filler-type fatty acid trapping section, filler pre-deodorization section, tympanic membrane deodorization section, and mammoth pump deodorization and decolorization section at the bottom are fixed together.

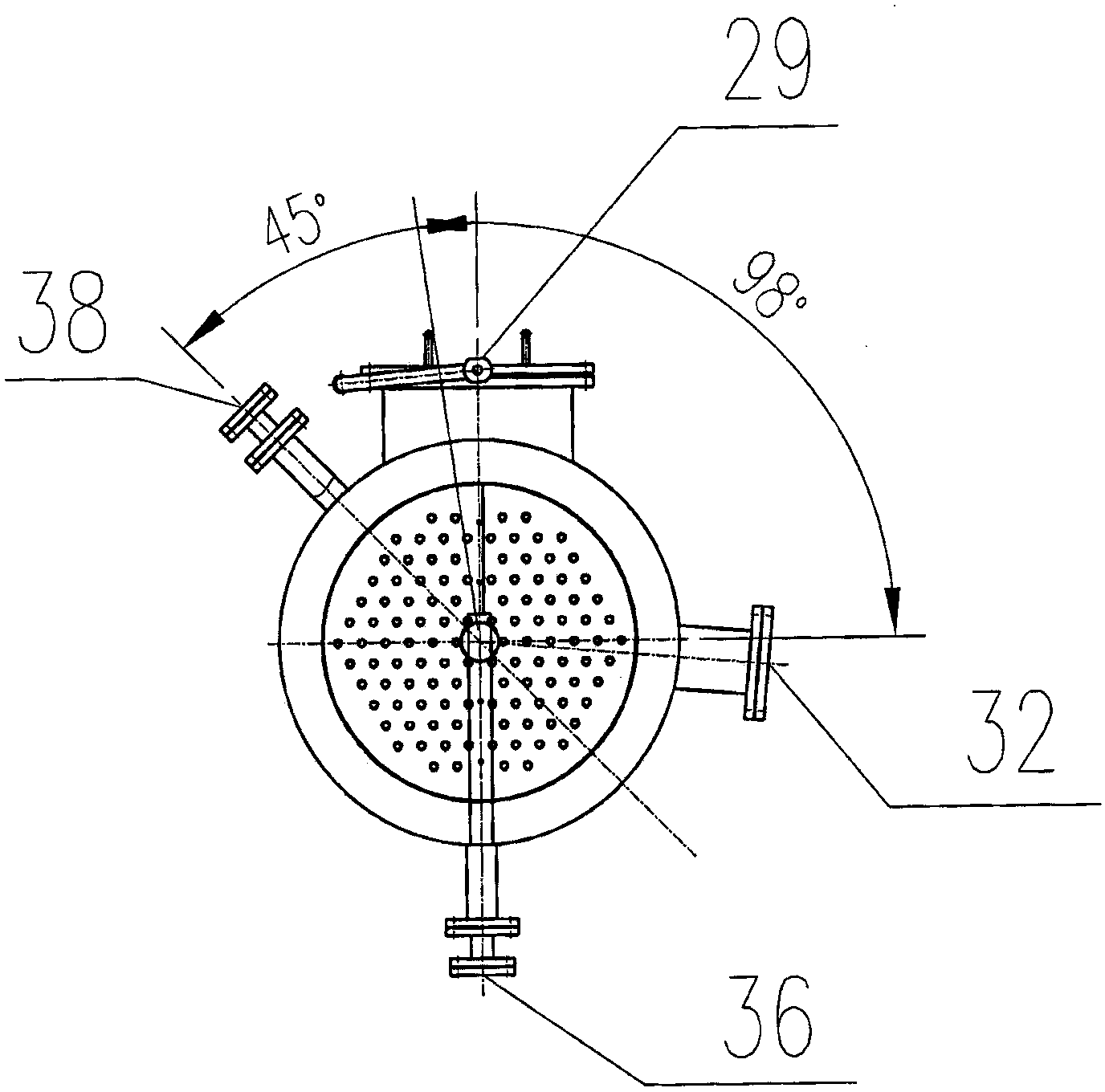

[0025] The structure of the packing type fatty acid trapping section is as follows: the waste gas outlet 29 is located at the top of the packing type fatty acid trapping section, the manhole 1 is located obliquely below the waste gas outlet, and a height of about 15 cm is arranged between the waste gas outlet 29 and the manhole 1. The foam trapping net 30 prevents the fatty acid foam from being ejected from the was...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com