Processing method for camellia seed oil with aromatic flavor and nutrition

A technology of Camellia oleifera seed oil and processing method, which is applied in the direction of edible oil/fat, fat oil/fat production, fat oil/fat refining, etc. It can solve the problems of loss of strong aroma components, reduce oil yield, and can not be very strict, so as to achieve reduction The loss of nutrients, the improvement of flavor components, and the effect of excellent quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

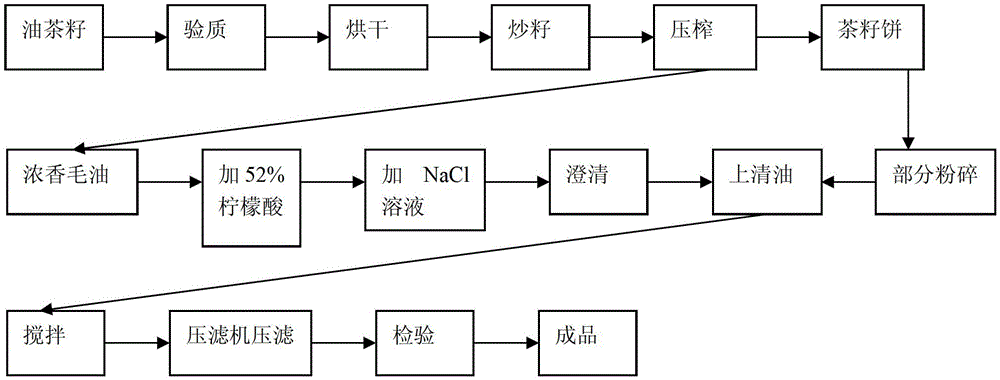

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1: with moisture 11%, impurity content 0.48%, after the Camellia oleifera seed that has no mildew, no moth is shelled, dry, and dry material is measured to contain 48% oil, and the moisture of drying is 7.6%; The dried Camellia oleifera seeds are put into a rotary oven, fried at 130°C for 40 minutes, and then oil-pressed by a screw press while still hot; the measured residual oil of the pre-pressed cake after oil-pressing is 5.5%. Camellia oleifera seed cake, which accounts for about 5% of the total amount of camellia oleifera seed cake after pressing, is ground into powder with a grinder with an aperture of 1.5m, and dried. The measured moisture content is 2.9%. After the pressed oil is filtered by a filter press, add 52% citric acid solution at room temperature according to 0.10% of the pressed oil mass, and react for 90 minutes under continuous stirring conditions; Add 0.5% of the mass of NaCl solution with a concentration of 5%, continuously stir and reac...

Embodiment 2

[0022] Embodiment 2: after moisture 10%, impurity content 0.42%, no mildew, no worm-eaten Camellia oleifera seeds shelled, then dried, the dried material measured oil content was 50%, and the dried moisture was 7.1%; The dried Camellia oleifera seeds are put into a rotary oven, fried at 140°C for 30 minutes, and then oil-pressed by a screw press while still hot; the measured residual oil of the pre-pressed cake after oil-pressing is 5.8%. Camellia oleifera seed cake, which accounts for about 5% of the total amount of camellia oleifera seed cake after pressing, is ground into powder with a pulverizer with an aperture of 1.5m, and dried. The measured moisture content is 2.6%. After the pressed oil is filtered by a filter press, add 52% citric acid solution at room temperature according to 0.12% of the pressed oil mass, and react for 90 minutes under continuous stirring conditions; Add 0.5% of the mass of NaCl solution with a concentration of 5%, continuously stir and react for 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com