Optical coating composition, fluorescent optical membrane and preparation method thereof

An optical coating and composition technology, applied in the field of backlight display modules, can solve the problems of low market acceptance and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

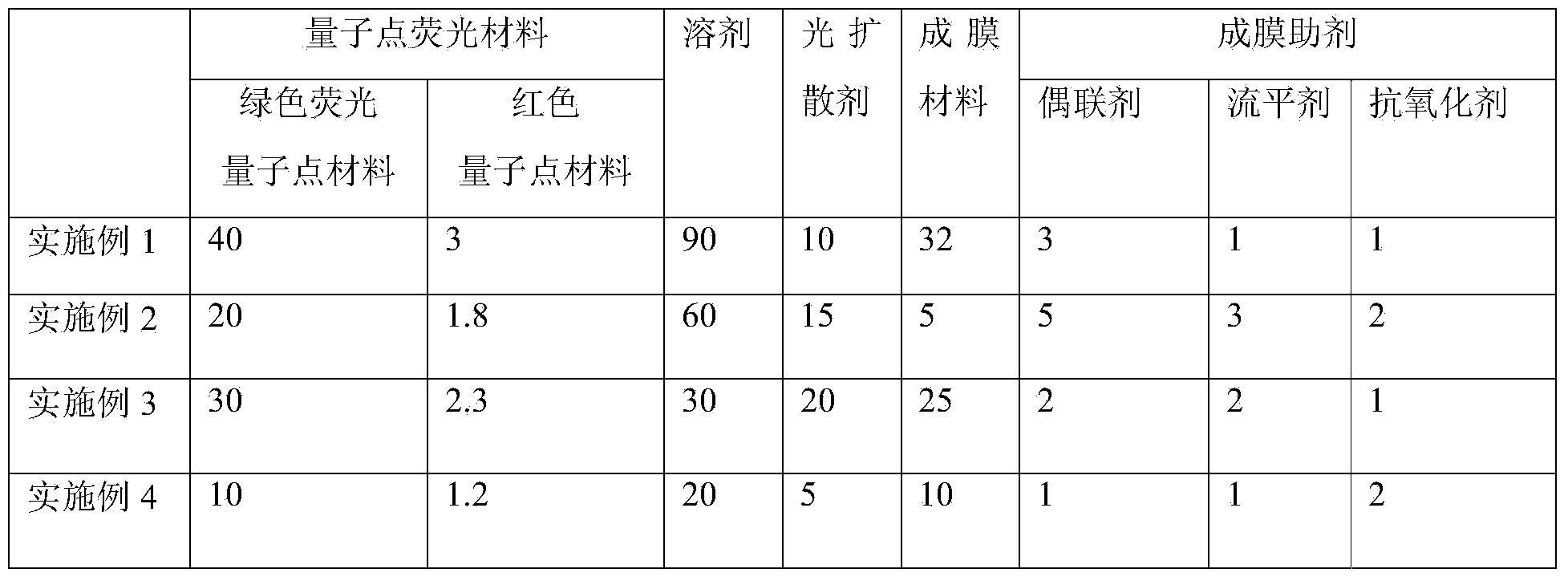

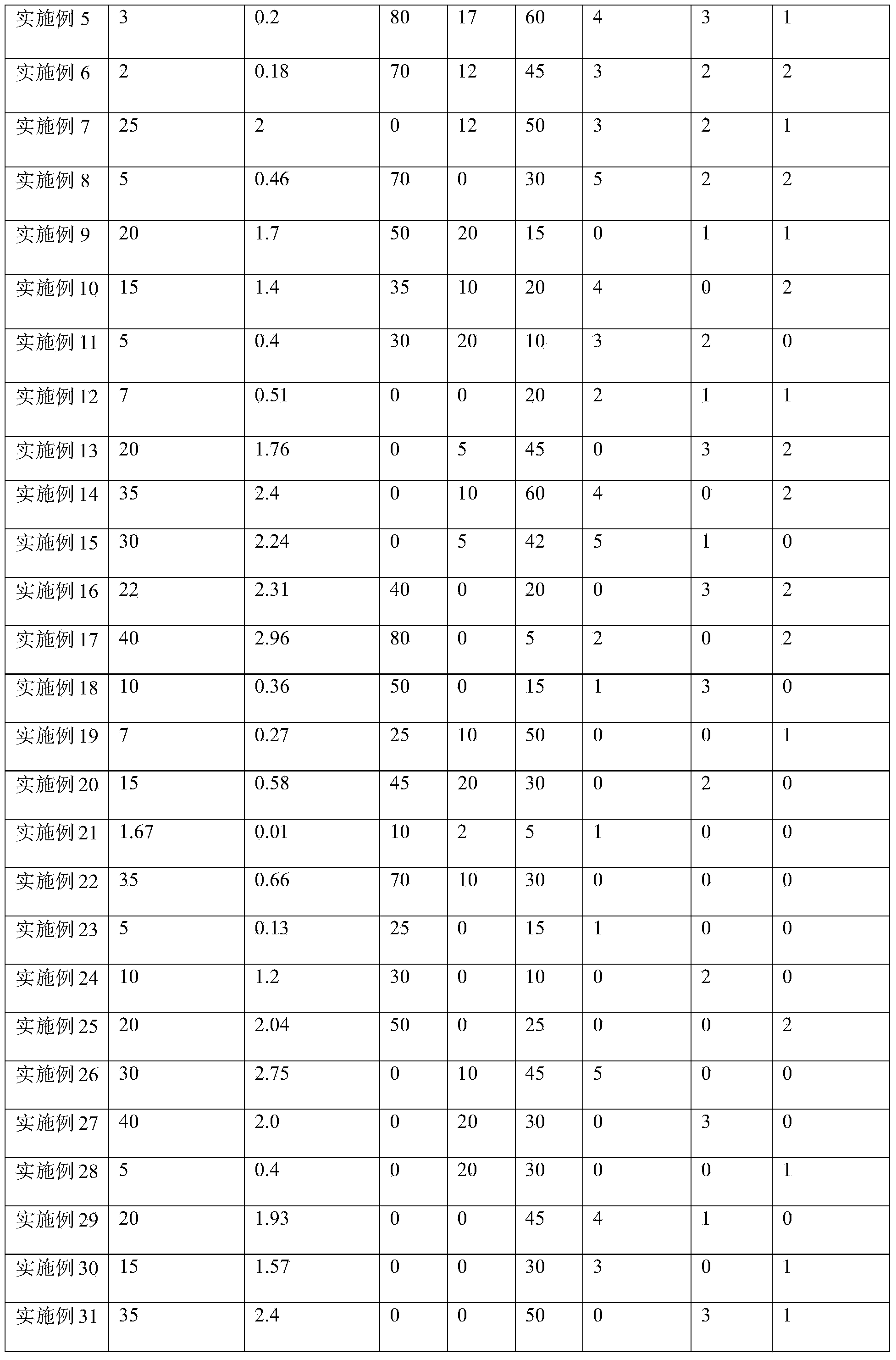

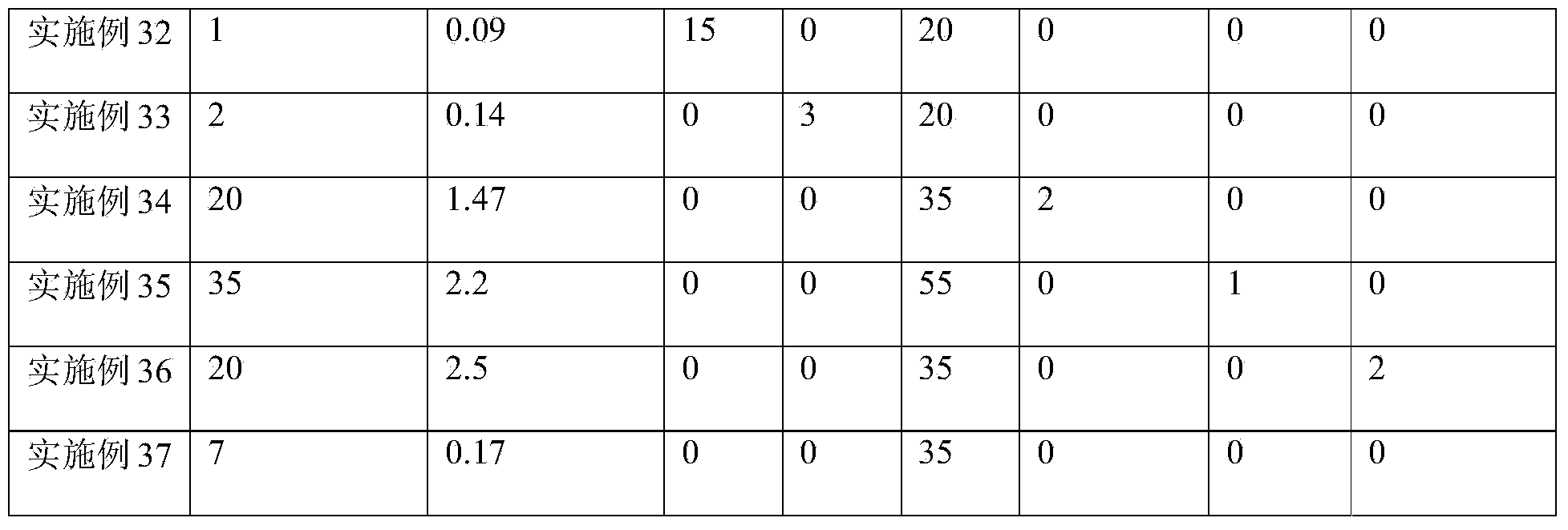

Examples

reference example 1

[0038] Reference example 1: Synthesis of red fluorescent quantum dot material (chemical composition CdZnSeS / ZnS)

[0039] Add 24mmol of zinc acetate, 1.2mmol of selenium powder, 31ml of oleic acid and 30ml of hexadecane into a three-necked flask with a condenser and a thermometer, vacuumize at 150°C for 20min, fill with nitrogen, heat to 260°C, react for 2h, then drop oil Cadmium 1-octadecene solution, real-time monitoring product fluorescence emission peak wavelength by miniature optical fiber spectrometer (Ocean optics USB4000), when the desired light emission peak wavelength is reached (add 7.7ml of cadmium source dropwise at this time), then add dropwise according to The required amount of sulfur source is obtained by calculating the addition amount of the previous reactants, that is, continue to add 6ml of 1-octadecene solution with a concentration of 4mol / L 1-octylthiol dropwise, and control the dropwise completion within 6 minutes. The reaction was continued at 260 °C f...

reference example 2

[0040] Reference example 2: Synthesis of green fluorescent quantum dot material (chemical composition CdZnSeS / ZnS)

[0041] Add 8mmol of zinc acetate, 0.4mmol of selenium powder, 5.2ml of oleic acid and 15ml of 1-octadecene into a three-necked flask with a condenser tube and a thermometer, vacuumize at 120°C for 60min, fill with nitrogen, heat to 240°C, and then slowly drop Add the prepared 1-octadecene solution of cadmium oleate, and monitor the product fluorescence emission peak wavelength in real time through a micro fiber optic spectrometer (Ocean optics USB4000). Then dropwise add the required sulfur source calculated according to the amount of the previous reactant, that is, continue to drop 2ml of the sulfur source prepared in Example 5, and control it to drop in 40min, then add 1ml dodecanethiol dropwise, control it to drop in 20min. The reaction was continued for 120 minutes at 240°C. Cool to room temperature. Add toluene and stir evenly, add ethanol, centrifuge to ...

reference example 3

[0042] Reference example 3: Synthesis of red fluorescent quantum dot material (chemical composition InZnP / ZnS)

[0043] Add indium acetate (1mmol), hexadecanoic acid (3mmol), zinc acetate (8mmol), and 1-octadecene (20ml) into a dry and clean 50ml three-neck flask, vacuumize and change nitrogen for three rounds, and then Slowly raise the temperature to 220°C in the state, drop 0.8ml of 1.0M (TMS) 3P into the reaction system, keep it for 30mins, then raise the temperature to 260°C, and react for 2hours; slowly add 2.3ml of dodecanethiol dropwise into the above solution , kept at 260°C for 90mins, and cooled to room temperature under the protection of nitrogen. Divide the above-mentioned quantum dot solution cooled to room temperature into two 20ml centrifuge tubes, add about 2-3 times the volume of ethanol, stir until the turbid suspension appears, and centrifuge at 3500r / min for 3-5 minutes. Pour off the supernatant; centrifuge once again in the same way, pour off the supernat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| full width at half maximum | aaaaa | aaaaa |

| full width at half maximum | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com