Microwave dielectric ceramic material applicable to low temperature sintering and preparation method of microwave dielectric ceramic material

A technology of microwave dielectric ceramics and low-temperature sintering, which is applied in the field of functional ceramic materials, can solve the problem of high raw material cost, and achieve the effects of low raw material cost, low cost, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

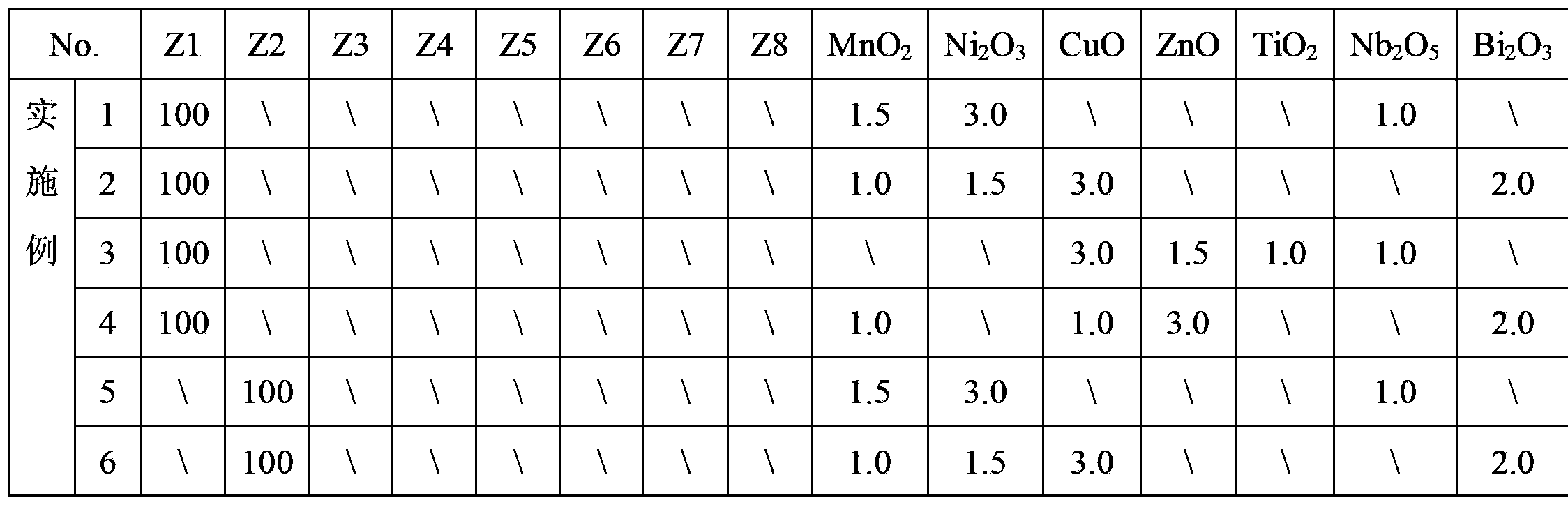

[0045] The microwave dielectric ceramic material prepared in the embodiment of the present invention includes 80-99.5wt% of the main material and 0.5-20wt% of the auxiliary material, wherein the main material includes aBaO-bTiO 2 -cZrO 2 , a, b and c are the molar percentages in the main material, 5%≤a≤35%, 65%≤b≤95%, 0%≤c≤15%, the auxiliary materials include CuO, ZnO, MnO 2 、Ni 2 o 3 or TiO 2 1 or a combination of at least 2 of them. The specific composition of the main ingredients is shown in Table 1. Among them, the raw material of the main material is BaCO 3 、TiO 2 and ZrO 2 Powder. The specific composition of the microwave dielectric ceramic material is shown in Table 2. Wherein, the raw materials of the auxiliary materials are oxides.

[0046] The raw materials of main ingredients and auxiliary ingredients can be replaced by one or a combination of at least two oxides, carbonates, phosphates, sulfates, hydroxides, nitrates or organic metal salts of the constitu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com