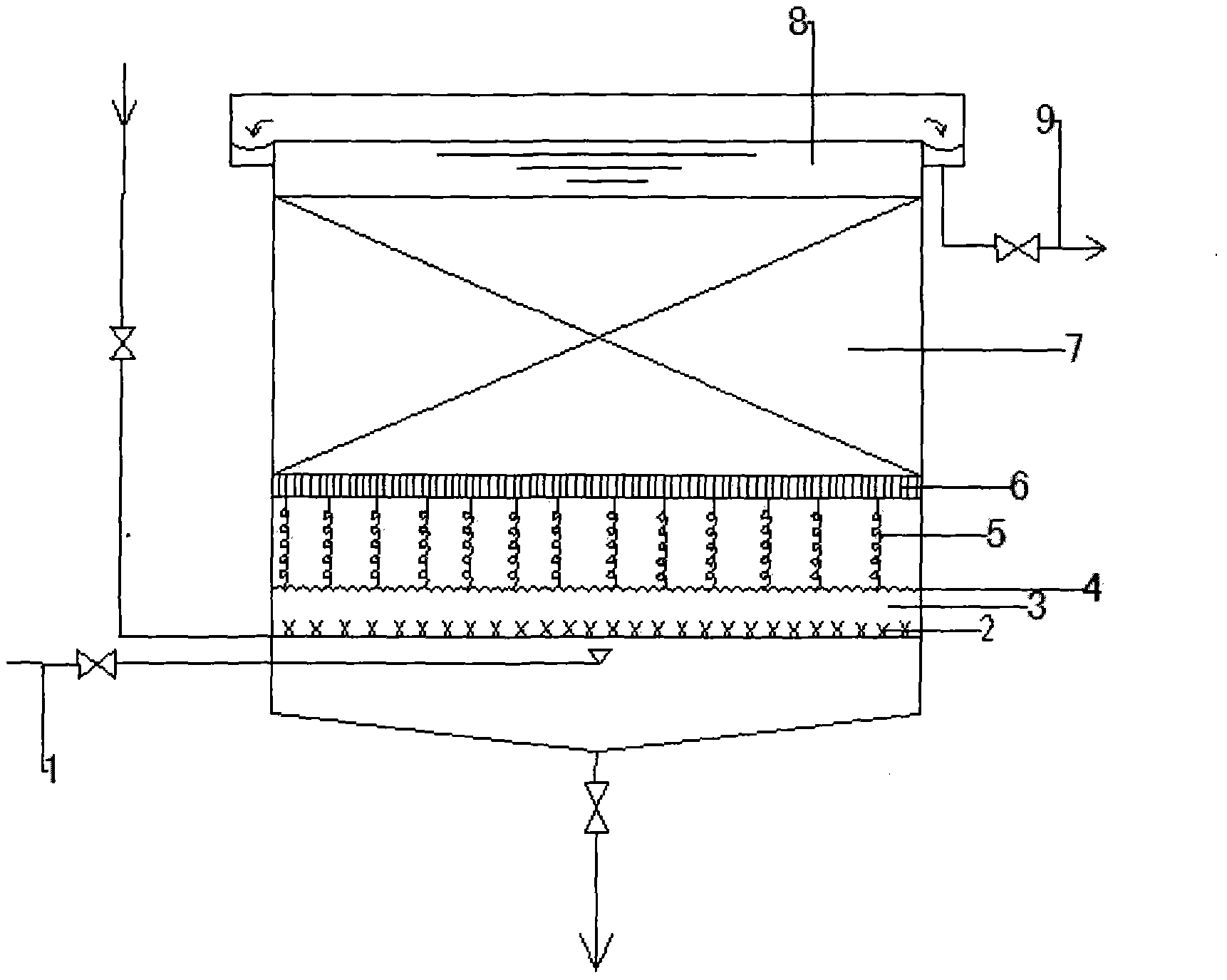

Biological aerating filter

A biological aeration filter and aeration technology, applied in the field of sewage treatment system, can solve the problems of high energy consumption and high investment, and achieve the effect of high treatment load, high transmission efficiency and good treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0015] Example 1: First select 40% fly ash, 5% cement, 10% anthracite, 8% gypsum, 3% magnesium chloride, 10% sludge and 24% water, mix and stir well, and cure in water bath at 50°C for 1 hour, demoulding and curing for 1 hour , the roasting temperature is 600°C, and the roasting time is 0.5h. The removal rate of BOD per kilogram of filter material can reach 1.5; the average concentrations of COD, ammonia nitrogen, total nitrogen and total phosphorus in the water are 76mg / L, 13mg / L, respectively. 21mg / L, 1.94mg / L domestic sewage, the aeration time is 10 minutes, the biological aeration gas-liquid ratio is 15:1, the average concentration of COD, ammonia nitrogen, total nitrogen and total phosphorus in the effluent after treatment is 11.7mg / L , 4mg / L, 4.7mg / L and 0.04mg / L, the removal rates of COD, ammonia nitrogen, total nitrogen and total phosphorus are 85%, 73%, 77.7% and 98% respectively, and the treated effluent meets the " Water Quality Standards for Domestic Miscellaneous ...

example 2

[0016] Example 2: First select 41% fly ash, 8% cement, 15% anthracite, 6% gypsum, 5% magnesium chloride, 8% sludge and 17% water, mix and stir thoroughly, and cure in a water bath at 55°C for 1.5 hours, demoulding and curing 1.5h, the roasting temperature is 600°C, and the roasting time is 0.8h, and the removal rate of 1.8 BOD can be achieved per kilogram of filter material. The average concentration of influent COD, ammonia nitrogen, total nitrogen and total phosphorus is 80mg / L, 15mg / L, 25mg / L, 1.56mg / L respectively, the aeration time is 15 minutes, and the biological aeration vapor-liquid ratio is 20 : 1, the average concentration of COD, ammonia nitrogen, total nitrogen and total phosphorus in the effluent after treatment is 12.3mg / L, 5mg / L, 6.8mg / L and 0.087mg / L, and the removal rate of COD, ammonia nitrogen, total nitrogen and total phosphorus They are 84.6%, 66.6%, 72.8% and 94.4% respectively, and the treated water meets the "Water Quality Standard for Miscellaneous Do...

example 3

[0017] Example 3: First select 42% fly ash, 6% cement, 12% anthracite, 5% gypsum, 4% magnesium chloride, 6% sludge and 25% water, mix and stir thoroughly, maintain in a water bath at 60°C for 2 hours, and remove the mold for 2 hours , the roasting temperature is 600°C, and the roasting time is 1h. The removal rate of BOD per kilogram of filter material can reach 2.0. The average concentrations of COD, ammonia nitrogen, total nitrogen and total phosphorus in the influent are 85mg / L, 20mg / L and 30mg respectively. / L, 2.27mg / L domestic sewage, the aeration time is 20 minutes, the biological aeration gas-liquid ratio is 30:1, the average concentration of COD, ammonia nitrogen, total nitrogen and total phosphorus in the effluent after treatment is 14.3mg / L, 6.8mg / L, 9.1mg / L and 0.125mg / L, the removal rates of COD, ammonia nitrogen, total nitrogen and total phosphorus are 83.1%, 66%, 69.6% and 94.4% respectively, and the treated effluent meets the " Water Quality Standards for Domes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com