Preparation method of sargassum horneri matrix activated carbon

A technology based on activated carbon and copper algae, applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve the problems of copper algae industrialization and resource utilization are far from mature, and achieve improved pore expansion performance and low ash content , Strong specific adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

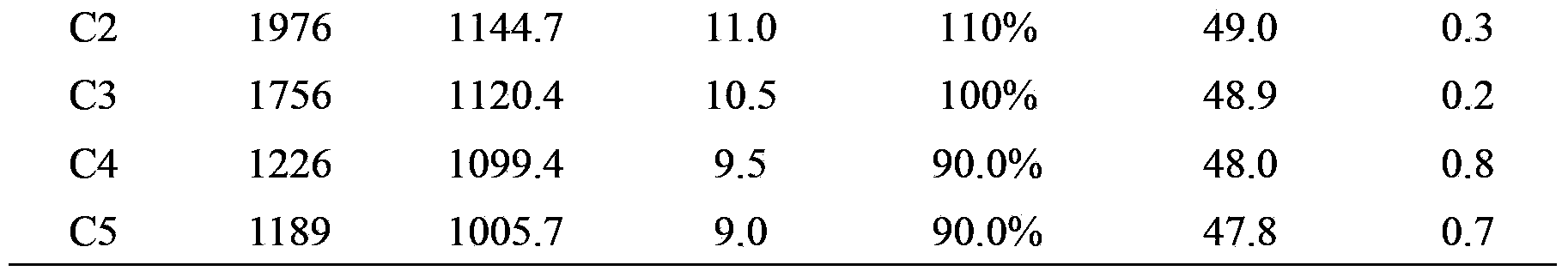

Examples

Embodiment 1

[0024] The copper algae collected in the Wenzhou sea area in southern Zhejiang were simply air-dried, washed with tap water to remove salt and impurities, then washed several times with deionized water, drained, and dried at 100°C for 24 hours to constant weight. The dried copper algae is crushed again, and the powder of 20-40 meshes is screened out. Weigh 10g of dry copper algae powder, add 100g of zinc chloride solution with a mass fraction of 50%, and stir at 25°C for 2h. Then the impregnation mixture was transferred to a vacuum tube furnace at a flow rate of 120L h -1 Under nitrogen protection, at 10°C·min -1 The temperature was raised to 500°C at a certain rate, and activated for 1h. Activate the obtained sample with 1mol·L -1 Boil the HCl solution for 30 minutes, continue to wash with boiling HCl solution for several times, wash with deionized water at 95°C until the pH remains unchanged, and then bake at 100°C for 24h to constant weight to obtain product A 1 .

[0...

Embodiment 2

[0027] The copper algae collected in the Wenzhou sea area in southern Zhejiang were simply air-dried, washed with tap water to remove salt and impurities, then washed several times with deionized water, drained, and dried at 100°C for 24 hours to constant weight. The dried copper algae is crushed again, and the powder of 20-40 meshes is screened out. Weigh 10g of dry copper algae powder, add 100g of zinc chloride solution with a mass fraction of 50%, and stir at 25°C for 10h. Then the impregnation mixture was transferred to a vacuum tube furnace at a flow rate of 100 L h -1 Under nitrogen protection, at 20°C·min -1 The temperature was raised to 600°C at a certain rate, and activated for 3 hours. Activate the obtained sample with 1mol·L -1 Boil the HCl solution for 30 minutes, continue to wash with boiling HCl solution for several times, wash with deionized water at 95°C until the pH remains unchanged, and then bake at 100°C for 24h to constant weight to obtain product A 2 ...

Embodiment 3

[0030] The copper algae collected in the Wenzhou sea area in southern Zhejiang were simply air-dried, washed with tap water to remove salt and impurities, then washed several times with deionized water, drained, and dried at 100°C for 24 hours to constant weight. The dried copper algae is crushed again, and the powder of 20-40 meshes is screened out. Weigh 10g of dry copper algae powder, add 100g of zinc chloride solution with a mass fraction of 30%, and stir at 25°C for 10h. Then the impregnation mixture was transferred to a vacuum tube furnace at a flow rate of 150L h -1 Under nitrogen protection, at 30°C·min -1 The temperature was raised to 600°C at a certain rate and activated for 1h. Activate the obtained sample with 1mol·L -1Boil the HCl solution for 30min, continue to wash with boiling HCl solution for several times, wash with deionized water at 95°C until the pH remains unchanged, and then bake at 100°C for 24h to constant weight to obtain product A 3 .

[0031] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com