Manufacturing technology for low-sulfur activated carbon

A technology for sulfur activated carbon and preparation process, applied in inorganic chemistry, non-metallic elements, carbon compounds, etc., can solve the problems of incomplete removal, lack of analysis and description, insufficient technical disclosure, etc. The effect of increasing porosity and improving adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

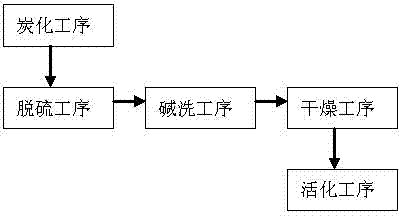

[0033] like figure 1 The low-sulfur activated carbon preparation process shown, the specific process is as follows:

[0034] 1. First soak the carbon-containing raw material in ammonium dihydrogen phosphate solution; carry out the carbonization process of smoldering treatment at a temperature of 180 to 360 degrees.

[0035] 2. Desulfurization process: Put the carbonized material in a fluoroplastic container; then, while stirring the carbonized material, mix a mixture of nitric acid with a weight ratio of 20% and a concentration of 60% and hydrochloric acid with a concentration of 30%. (The molar ratio of nitric acid to hydrochloric acid is 2:1) As a desulfurizing agent, it is sprayed into the carbonized material and soaked to oxidize the sulfur element in it; after being soaked in the desulfurizing agent, the sulfur element in the carbonized material is oxidized into a water-soluble compound, such as Sulfuric acid, sulfate, rinse twice with soft water, distilled water or dei...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com