Manufacturing technology for low-sulfur activated carbon

A technology of sulfur activated carbon and preparation process, which is applied in the direction of inorganic chemistry, non-metallic elements, carbon compounds, etc., can solve the problems of incomplete removal, lack of analysis and explanation, insufficient technical disclosure, etc., and achieve clean and microscopic sulfur removal. The effect of increasing porosity and improving adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

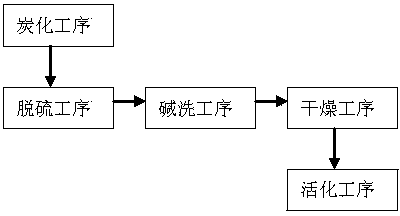

[0033] like figure 1 The low-sulfur activated carbon preparation process shown, the specific process is as follows:

[0034] 1. First soak the carbon-containing raw material in ammonium dihydrogen phosphate solution; carry out the carbonization process of smoldering treatment at a temperature of 180 to 360 degrees.

[0035] 2. Desulfurization process: Put the carbonized material in a fluoroplastic container; then, while stirring the carbonized material, mix a mixture of nitric acid with a weight ratio of 20% and a concentration of 60% and hydrochloric acid with a concentration of 30%. (The molar ratio of nitric acid to hydrochloric acid is 2:1) As a desulfurizing agent, it is sprayed into the carbonized material and soaked to oxidize the sulfur element in it; after the carbonized material is soaked in the desulfurizing agent, the sulfur element is oxidized into a water-soluble compound, such as Sulfuric acid, sulfate, rinse twice with soft water, distilled water or deionized ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com