Rolling schedule generation method for aluminum cold rolling mill based on material state and parameter curve

A technology of rolling schedules and parameter curves, applied in rolling mill control devices, metal rolling, metal rolling, etc., can solve the problems of not considering the requirements of finished product status, lack of systematic rolling schedule formulation technology, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

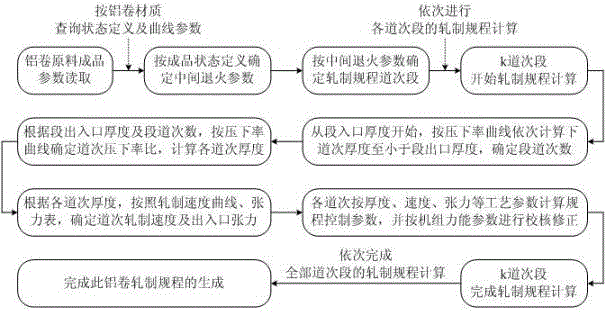

[0074] The invention provides a method for generating rolling schedules for aluminum cold rolling mills based on material states and parameter curves, such as figure 1 , the specific process:

[0075] 1) Read the finished product parameters of aluminum coil raw materials, and obtain the finished product state definition, reduction rate curve parameters, and rolling speed curve parameters of this material according to the material query;

[0076] 2) Determine the intermediate annealing parameters according to the finished state of the aluminum coil and according to the definition of the finished product state;

[0077] 3) According to the intermediate annealing parameters, determine the total number of rolling sections K (the rolling section number is k, k=0,...,K-1);

[0078] 4) k=0;

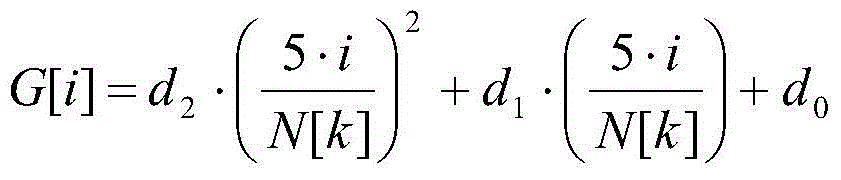

[0079] 5) In the k rolling section, starting from the thickness of the entrance of the section, the thickness of the next pass is sequentially calculated according to the reduction rate curve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com